Biodegradable Cellulose Paper Film: A Leap Towards Sustainability

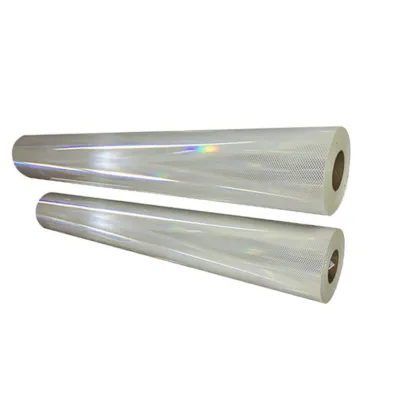

When we think of materials shaping the future, plastic often comes to mind—ubiquitous, resilient, but tragically harmful to the environment. However, OwnLikes introduces an innovative alternative: biodegradable cellulose paper film, marking a transformative chapter in eco-friendly packaging solutions. Unlike ordinary paper, which lacks flexibility and transparency, cellulose film is regenerated from natural materials like cotton pulp or wood pulp fibers. The product—dubbed "cellophane"—embodies flexibility, transparency, and a commitment to reducing environmental impact.

Cellulose film emerges not just as a substitute but as a game changer in packaging materials. Unlike plastic, which haunts ecosystems for centuries, cellulose decomposes into harmless substances like water and carbon dioxide. Paired with environmentally friendly pressure-sensitive glue that is water-based, this material ushers in a new era of sustainability. The adhesives used are biodegradable, aligning perfectly with circular economy ideals and environmental deplasticizing trends. This synergistic blend of eco-conscious components delivers a powerful punch against traditional packaging woes.

Furthermore, these biodegradable cellulose films from OwnLikes are customizable, ranging from white and blue to beige, meeting brand-specific aesthetic needs. Customization options also extend to logos and specific dimensions, allowing brands to retain their identities while contributing to environmental preservation. OwnLikes doesn't just offer a product; it crafts solutions that foster creativity while minimizing environmental degradation.

Apparel Industry Embraces Biodegradable Solutions Amid Rising Demand for Sustainability

Picture this: every year, the apparel industry manufactures approximately 80 billion pieces of clothing, with nearly 90 percent leveraging plastic for tags and labels. In this expansive network, brands, retailers, and consumers are rallying behind sustainable alternatives. The need to shift towards eco-friendly practices in clothing—ranging from safety and comfort to environmental sustainability—has never been more pronounced. Post-pandemic, the apparel industry finds itself at a critical juncture, accelerated by new consumption patterns that prioritize health and the planet's future.

OwnLikes stands at the forefront of this transformation with its cellulose paper films and biodegradable solutions. It's not merely about offering alternatives; it's about creating an entire ecosystem where biodegradable materials dominate, reducing reliance on harmful plastics. Clothing manufacturers, faced with rising consumer expectations around environmental stewardship, find in OwnLikes an ally capable of supporting the complex logistics of modern, eco-conscious production lines.

In the push towards sustainable practices, OwnLikes' products offer a seamless transition. They marry performance with ecological sensitivity, opening new avenues where both durability and biodegradability exist harmoniously. Whether it's for fixing price tags or labeling garments, these biodegradable materials serve multiple functions while fostering a waste-reducing life cycle.

OL008: OwnLikes’ Cellulose Paper Film Leading the Circular Economy Charge

Designed to meet the ever-growing demands of sustainability and the circular economy, OwnLikes' Cellulose Paper Film OL008 showcases what modern innovation can achieve when eco-conscious technologies converge. This product begins its life cycle with wood pulp fibers sourced from sustainably managed forests, ensuring the raw materials themselves reflect environmental stewardship from inception.

Key features of OL008 include its:

- Biodegradable nature ensuring sustainability from production to degradation.

- High transparency and tensile strength offering functional reliability.

- Advanced coating processes that bolster printability and moisture resistance.

Sustainability certificates from globally recognized institutions like the FSC (Certificate No. RINA COC-001475) and SGS Biodegradation Certification (ISO Certificate No.: GZIN2111064903MR) reinforce OL008’s ecological promise. The ability to retain strength akin to synthetic fibers like nylon and polyester without environmental harm positions OL008 as a beacon for the future of packaging.

Recycling is not an afterthought with OL008; it’s embedded in the product's ethos. By reducing reliance on petroleum-based materials and utilizing renewable resources, OwnLikes ensures that every product phase—from creation to decomposition—aligns with broader deplasticizing goals. OL008's raw materials, driven by biomass sources, reflect a commitment to innovation that speaks directly to consumer concerns about resource overconsumption and waste management.

Tailored Solutions: Customizing the Future of Packaging

Every business has unique needs, and OwnLikes meets this diversity with tailored solutions. Whether it's adjusting surface material weight, applying laser shading, or selecting from a variety of adhesive types—such as water-based, hot melt, oil adhesive, or removable glue—OwnLikes molds its offerings to suit customer requirements.

OwnLikes offers three specific custom schemes for biodegradable cellulose paper film, allowing businesses the flexibility to choose according to their adhesive needs:

- Biodegradable cellulose paper film (25-40u thickness) paired with water-based glue and customer-specified substrates.

- Biodegradable cellulose paper film (25-40u thickness) coupled with oil adhesive, adhering to grid or transparent bottom preferences.

- Biodegradable cellulose paper film (25-40u thickness) matched with movable adhesive for versatile application scenarios.

This isn’t merely customization—it’s an alignment of operational efficiency and environmental duty. Whether clients need specific sizes, logo prints, or custom label rolls, OwnLikes brings a precision-based, customer-centric approach that fuels the next wave of eco-conscious branding and labeling solutions.

Validating the Future of Materials: OwnLikes’ Commitment to Transparency

Critical questions surface in any industry transitioning to eco-friendly solutions. How can one ensure that what appears like traditional membrane material is truly biodegradable? OwnLikes provides not just assurances but evidence through simple, effective testing methods: ignition, smell, and tear tests offer immediate verification. Quick combustion, a paper-like odor when burned, and easy longitudinal tearing distinguish true cellulose film from plastic lookalikes.

Supporting documentation further dispels doubts. From the EU Industrial Composting Certificate to the FSC Forest Certificate, OwnLikes equips its clientele with the proof points necessary to uphold environmental commitments. Ingesting a minor grammatical miscue here and there, OwnLikes shows that while its technical documents may stumble, its products never falter on performance or sustainability.

OwnLikes assures customers that their biodegradable products, despite being completely degradable in 90 days under the right conditions, remain resilient through the rigors of shipping, storage, and display. There’s no need for premature degradation concerns unless subjected to prolonged microbial exposure—unlikely during normal product lifecycles.

Moreover, moisture resistance—a crucial factor in product usability—ensures that despite its paper base, OwnLikes' biodegradable film stands strong even in humid environments. OwnLikes subjected OL008 to high temperatures, humidity, and other rigorous tests, successfully meeting requirements for coatings, embossing, heat sealing, and more. This isn't just eco-friendly material; it's an adaptable solution ready to meet modern packaging needs.

Biodegradability, Performance, and Environmental Wins: The Special Advantages

Why make the shift from traditional OPP/PET films to biodegradable alternatives? OwnLikes’ biodegradable cellulose film not only outperforms plastic counterparts in terms of environmental friendliness but also excels in functional qualities:

- Antistatic properties, ensuring smoother handling and application processes.

- Stable corona values, essential for high-quality printing outcomes.

- Rupture resistance, keeping your products safe during transit or display.

- Odorless, non-toxic nature, aligning perfectly with health and safety standards.

- Tearability, providing ease of use for both consumers and businesses.

These films further alleviate the need for complex taxation or special tariffs under increasingly strict environmental regulations, creating a smoother, greener operational landscape for customers.

Finally, imagine the freedom of choosing packaging that poses no threat to marine life or ecosystems once discarded. With biodegradable materials that decompose into harmless organic matter, OwnLikes doesn't just limit its products' environmental footprint—it erases it.

Closing Thoughts: OwnLikes’ Role in a Sustainable Tomorrow

As we confront the realities of plastic waste, businesses must step forward as pioneers of sustainable change. OwnLikes not only rises to this occasion but drives it, showing that performance and planetary care are far from mutually exclusive. Through its biodegradable cellulose paper films and eco-friendly adhesives, OwnLikes carves a new path—one where packaging becomes a solution rather than a problem.

The overarching questions are answered, the game is changed, and brands are given a clear avenue towards sustainability without compromising the integrity of their products or messages. The power lies in the shift, and OwnLikes hands you the key. It’s time to embrace biodegradable innovation. The future, after all, waits for no one. But with OwnLikes, it's a future we can all look forward to—lighter, brighter, and infinitely more sustainable.

We offer comprehensive technical support, including free professional labeling solutions, advice on label materials and adhesive selection, as well as online/offline assistance from professional software and hardware engineers. Service email: andy@ownlikes.cn. In pre-sales, we leverage our extensive experience in specialty labeling projects to provide clients with the most suitable hardware solutions. Additionally, all our label barcode printers and scanners come with a three-year free warranty, demonstrating our confidence in our products.