Unveiling Biodegradable Cellulose Film: A Natural Alternative

Imagine a material that rivals plastic in flexibility and transparency yet holds an eco-friendly edge—cellulose film. At OwnLikes, we specialize in transforming cotton pulp or wood pulp into regenerated cellulose membranes through a unique process. This "cellophane" is no ordinary paper. While it mirrors the strength and sheen of synthetic films, it’s crafted entirely from renewable resources, setting it apart in the world of industrial labeling and packaging. This natural alternative isn't just a theoretical concept—it’s here, replacing plastic in practical, everyday applications.

Cellulose film isn’t the end of the story. The adhesive that accompanies it is equally revolutionary. OwnLikes’ pressure-sensitive glue is a biodegradable, water-based concoction that complements the film's environmental promise. Comprised of butyl acrylate, water, rosin resin, and a medley of additives, this glue breaks down harmlessly into water and carbon dioxide. It's a far cry from traditional adhesives, which persist in landfills for centuries. This eco-glue can also be recycled alongside waste cartons, contributing to a circular economy where nothing goes to waste.

But the customization doesn't stop there. The cellulose film can be tailored to suit specific aesthetic and functional needs. Whether it’s a splash of color—white, red, blue, or beige—or custom logos and dimensions, OwnLikes ensures that brands don’t have to compromise on identity or values. In a world increasingly driven by sustainability, these biodegradable films aren't just a product; they're a statement.

The Apparel Industry’s Green Shift: From Plastic to Biodegradable Solutions

Each year, the fashion industry churns out around 80 billion garments. A staggering 90 percent of these use plastic for price tags and product information labels. As environmental awareness seeps into every facet of consumer behavior, brands and retailers face mounting pressure to swap out plastic for sustainable alternatives. This is where OwnLikes steps in, offering biodegradable cellulose film as an answer to the apparel industry's environmental dilemma.

Post-pandemic, the shift toward eco-conscious consumption has only accelerated. Consumers, now more than ever, prioritize health, comfort, and sustainability in their clothing choices. They demand that brands take responsibility, pushing the industry toward a greener future. OwnLikes rises to this challenge, delivering biodegradable solutions that meet the stringent demands of modern apparel production without compromising on quality or durability.

Our cellulose paper films and bio-based materials are engineered for the circular economy. They don’t just replace plastic; they outperform it. Take, for example, our Cellulose Paper Film OL008—designed specifically to align with sustainable development and deplasticizing trends. It marries high transparency with impressive tensile strength, ensuring that even the most demanding packaging needs are met. And with an FSC Certification and an SGS Biodegradation Certification, OL008 doesn’t just promise sustainability; it proves it.

The Birth of OL008: Combining Innovation and Sustainability

OwnLikes’ Cellulose Paper Film OL008 is the product of extensive R&D, blending cutting-edge technology with a commitment to environmental preservation. Derived from sustainably sourced wood pulp fibers, OL008 embodies the essence of a biodegradable and sustainable life cycle. The innovative coating process we’ve developed enhances both printability and moisture resistance, making it a versatile solution for a range of applications.

Here's a snapshot of OL008’s standout features:

- Sustainably sourced raw materials from certified forests.

- Complete biodegradability, verified by SGS.

- High transparency and tensile strength for reliable performance.

- Enhanced coating for improved moisture resistance and print quality.

These certifications and features underscore our commitment to creating products that not only meet but exceed the environmental standards set by the EU Plastics Regulation. By integrating OL008 into your operations, you're not just choosing a material; you're choosing to be part of a movement toward a more sustainable future.

Catering to Diverse Needs: Customization at Its Best

One size doesn’t fit all, especially in the world of industrial packaging and labeling. That’s why OwnLikes goes above and beyond to offer tailored solutions that meet the specific needs of our clients. From surface material weight selection to dyeing, laser shading, and inkjet coating, our customization options are as vast as they are precise.

We understand that adhesive needs vary, which is why we provide a range of glue coating options: water-based, hot melt, oil-based, and removable adhesives. And for those looking to print logos on release paper or select specific paper thicknesses, OwnLikes has got you covered.

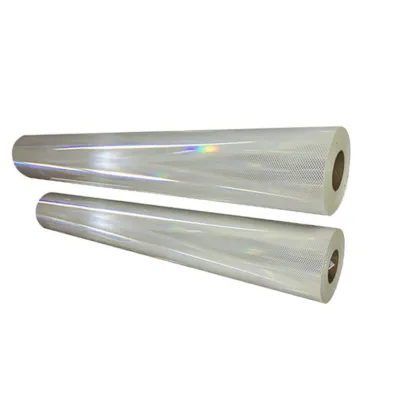

Our biodegradable cellulose paper film can be customized into three distinct schemes, giving clients the flexibility to choose based on their specific adhesive requirements:

- Biodegradable cellulose paper film (25-40u thickness) with water-based glue and customer-specified substrates.

- Biodegradable cellulose paper film (25-40u thickness) with oil adhesive, tailored to grid or transparent bottom needs.

- Biodegradable cellulose paper film (25-40u thickness) with movable adhesive, adaptable to grid or transparent bottom specifications.

Whether you're looking to adjust size specifications, print logos, or customize automatic labeling roll materials, OwnLikes has the expertise and technology to make it happen.

Verifying the Authenticity of Biodegradable Cellulose Film

With innovation comes skepticism, and rightly so. How can you be sure that what you're getting is genuinely biodegradable? OwnLikes provides three quick verification methods to dispel any doubts:

- Ignition Test: In a safe environment, ignite the material. It should burn quickly without dripping, leaving behind paper ash.

- Smell Test: When burned, the smell should resemble that of burning paper products.

- Tear Test: The material should tear easily longitudinally.

It's these simple, yet effective tests that confirm the authenticity of our biodegradable cellulose film. To further solidify trust, we provide supporting documents, including the EU Industrial Composting Certificate, EU Home Composting Certificate, FSC Forest Certificate, RoHS report, FDA food-grade certification, and Halogen reports.

But what about moisture resistance? After all, paper and water don’t traditionally mix well. Rest assured, OwnLikes’ cellulose film is moisture-proof, having passed rigorous tests involving high temperatures and humidity. The advanced coating process ensures that the film can withstand various post-processing techniques such as shallow bump, embossing, UV printing, and high-frequency heat sealing.

Answering the Tough Questions: Degradation, Recycling, and Beyond

One common concern surrounding biodegradable materials is the fear of premature degradation. Will the product disintegrate before reaching the consumer? The answer is a resounding no. Our biodegradable cellulose film requires specific conditions—microorganisms, temperature, and humidity—to break down over 90 days. Under normal circumstances, the material remains robust and reliable throughout its intended use cycle.

When compared to traditional OPP/PET films, OwnLikes’ biodegradable cellulose film boasts several advantages:

- Complete biodegradability into harmless substances like protein and glucose.

- Antistatic properties for smoother handling.

- High transparency and color reproduction for superior print quality.

- Strong rupture resistance and high barrier properties for reliable protection.

- Odorless and non-toxic when burned.

- Easier to tear longitudinally, meeting special packaging needs.

- Exemption from tariffs under plastic orders, helping you avoid additional costs.

What’s more, our biodegradable materials can be recycled along with paper, requiring no separate processing. When regenerated, the proportion of finished products is minimal, ensuring efficient use of resources.

A Vision for the Future: Biodegradable Solutions for a Plastic-Free World

As the EU Plastics Regulation tightens and the world moves toward stricter environmental standards, the need for biodegradable solutions becomes ever more pressing. OwnLikes isn’t just preparing for this future—we’re helping to shape it. Our cellulose film materials aren’t just an alternative to plastic; they’re a step toward a plastic-free world, where packaging no longer contributes to pollution and waste.

Picture a world where marine life swims freely without the threat of plastic bags, and ecosystems thrive without the shadow of non-biodegradable waste. This vision isn’t a distant dream; it’s a tangible reality that OwnLikes is actively working toward. With biodegradable cellulose film leading the charge, we can move toward a future where both industry and environment coexist harmoniously.

The power lies in the shift, and OwnLikes gives you the tools to make that shift today. Whether you’re in the apparel industry or any sector that relies on labeling and packaging, biodegradable cellulose film is your ticket to sustainability. It’s not just about meeting regulations; it’s about making a real difference. So, will you join us in paving the way for a greener tomorrow? The choice is yours, but the path is clear.

We offer comprehensive technical support, including free professional labeling solutions, advice on label materials and adhesive selection, as well as online/offline assistance from professional software and hardware engineers. Service email: andy@ownlikes.cn. In pre-sales, we leverage our extensive experience in specialty labeling projects to provide clients with the most suitable hardware solutions. Additionally, all our label barcode printers and scanners come with a three-year free warranty, demonstrating our confidence in our products.