Introduction to PLA Film Roll: A Sustainable Packaging Revolution

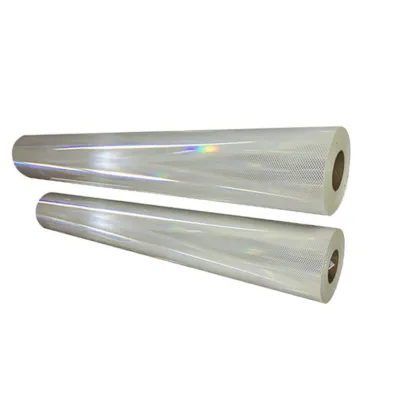

In an era where sustainability intersects with innovation, the introduction of 100% biodegradable plastic packaging in the form of PLA film roll material stands as a beacon of environmental responsibility. Polylactic Acid (PLA) film, derived from renewable resources such as cornstarch or sugarcane, offers a sustainable alternative to traditional petroleum-based plastic films. PLA film is not only biodegradable but also compostable, making it a front-runner in the race toward eco-friendly packaging solutions.

PLA film roll material differentiates itself through its unique composition and environmental impact. Unlike ordinary plastic films that persist in landfills for centuries, PLA films break down naturally, reducing the environmental footprint. Their versatility in application, ranging from food packaging to labeling and textile wrapping, illustrates their adaptability across industries. With mounting global concerns over plastic pollution, PLA film rolls pave the way for responsible packaging choices that resonate with both businesses and consumers.

Driving Forces Behind PLA Film Adoption in the Packaging Industry

The global push for sustainability has spurred industries to rethink packaging materials. With approximately 80 billion pieces of clothing manufactured annually, and a staggering 90 percent relying on some form of plastic for labels and price tags, the textile industry exemplifies a prime sector for change. PLA film rolls present an eco-friendly option for labeling and packaging, aligning with the growing consumer demand for environmental preservation.

The post-pandemic consumer landscape reflects a heightened awareness of personal health and environmental sustainability. People now prioritize products that not only serve functional needs but also align with their values of ecological and social responsibility. Brands and retailers face mounting pressure to adopt eco-friendly packaging solutions like PLA film, driven by this consumer shift towards sustainability. OwnLikes, through its continuous innovation, strives to provide eco-label solutions that meet these evolving demands, transforming packaging standards industry-wide.

Technological Innovation and Sustainability at OwnLikes

At OwnLikes, our pursuit of sustainable development propels us to integrate cutting-edge technology into the creation of biodegradable packaging materials. Our flagship PLA film roll, designed to address the environmental challenges of plastic pollution, is crafted using advanced bio-based materials. By leveraging both domestic and international technological advancements, we have developed PLA films that are not only biodegradable but also exhibit exceptional performance characteristics.

Key Features of Our PLA Film Roll Material:

- Raw Material Source: Derived from sustainable and renewable plant-based resources.

- Biodegradable Lifecycle: The entire product lifecycle is designed to be sustainable, culminating in complete biodegradation without harmful residues.

- High Transparency and Tensile Strength: Innovative coating processes enhance both the visual appeal and mechanical properties of the film, ensuring robust protection and presentation for packaged goods.

- Certifications: Our PLA film rolls hold certifications such as FSC (Forest Stewardship Council) and SGS Biodegradation Certification, attesting to their environmental credentials.

Through technological innovation and sustainable material choices, we contribute to the circular economy, focusing on reducing waste and promoting recycling initiatives. Our products align with the principles of sustainable development, where renewable resources replace oil-based materials, and packaging reduction initiatives prioritize eco-conscious designs.

Sustainable Solutions and Circular Economy Initiatives

OwnLikes offers comprehensive solutions that encompass a range of bio-based materials, degradable films, and moisture barrier coatings. Our dedication to sustainability is reflected in every facet of our product development, from conceptualization to recycling. PLA film rolls form an integral part of this initiative, embodying our commitment to environmental stewardship.

Recycling, Renewal, and Degradation:

- Recycling: Our PLA film materials can be recycled, allowing for integration into new product cycles.

- Renewable Resources: PLA film is derived from biomass resources such as corn and sugarcane, aligning with our goal of reducing reliance on oil-based plastics.

- Reduction: Through innovative design and production techniques, we reduce material thickness and weight, minimizing plastic use while maintaining product integrity.

- Degradability: Our PLA film rolls are fully biodegradable, breaking down under industrial, oxygen, and photodegradable conditions.

Customization Options to Meet Diverse Industry Needs

Understanding that each business has unique packaging and labeling requirements, OwnLikes offers a range of customization options for our PLA film rolls. From varying material weights and dyeing processes to laser shading and inkjet coatings, we ensure our clients can tailor our products to their exact specifications. Our glue coating options, including water-based, hot melt, oil-based, and removable adhesives, allow for versatile applications across industries.

Customization Highlights:

- Size Specifications: Tailor the PLA film roll to meet specific dimensional requirements.

- Logo Printing: Showcase brand identity by printing logos and designs directly on the film.

- Automated Labeling and Roll Material: Customize for automatic labeling processes and cutting, enhancing operational efficiency.

Our tailored solutions ensure that whether it’s in the apparel, food, or electronics industry, our PLA film rolls provide both functional and aesthetic benefits while prioritizing sustainability.

Distinguishing PLA Film from Traditional Plastics

A common question regarding PLA film roll material pertains to its visual similarity to traditional plastic membranes. While the appearance may seem alike, PLA film is fundamentally different in both composition and environmental impact. Here’s how you can quickly verify the distinction:

- Ignition Test: In a controlled environment, ignite a small piece of the film. PLA film will burn quickly without dripping and will leave behind paper-like ash.

- Smell Test: When burned, PLA film emits the smell of burnt sugar or plant-based materials, unlike the harsh chemical odor of plastic.

- Tear Test: PLA film tears easily along the longitudinal axis, unlike plastic, which tends to stretch and resist tearing.

PS: PLA film is a transparent paper-like material, not a plastic film.

Certifications and Compliance: Proof of Sustainability

OwnLikes ensures that all our biodegradable PLA film rolls meet global environmental and safety standards. Our certifications provide clients with the assurance of quality, sustainability, and safety.

Key Certifications:

- EU Industrial Composting Certificate: Validates the industrial compostability of our PLA film.

- EU Home Composting Certificate: Confirms the suitability of our film for home composting.

- FSC Forest Certification: Reflects our commitment to sourcing materials from sustainably managed forests.

- ROHS Report: Ensures our products comply with restrictions on hazardous substances.

- FDA Food Grade Certification: Demonstrates that our PLA film is safe for food contact.

- Halogen Reports: Confirms the absence of harmful halogen compounds in our materials.

These certifications not only attest to the quality of our PLA film rolls but also provide peace of mind to businesses looking to transition to sustainable packaging solutions.

Performance Under Stress: Testing and Applications

Our PLA film rolls undergo rigorous testing to ensure they meet high standards of durability, printability, and environmental safety. Through tests simulating high temperature, humidity, and various post-processing applications such as UV printing, embossing, and heat sealing, our films consistently demonstrate exceptional performance.

Applications and Compatibility:

- High-Temperature and Humidity Resistance: PLA film maintains integrity under conditions of 60% high temperature and 85% high humidity over 48 hours.

- Versatile Printing and Coating: Compatible with a range of printing processes, including UV, screen printing, and gold stamping.

- Durability: Suitable for packaging needs across industries, from color boxes and handbags to books and labels.

Addressing Concerns: Will PLA Film Degrade Before Use?

A common concern with biodegradable materials is whether they will degrade before reaching the end consumer. At OwnLikes, we ensure our PLA film rolls are engineered for durability during their useful life. Biodegradation requires sustained exposure to specific environmental conditions—including the presence of microorganisms, temperature, and humidity—over a period exceeding 90 days. Therefore, clients need not worry about premature degradation under normal usage and storage conditions.

Comparative Advantages Over OPP and PET Films

When compared to traditional OPP and PET films, PLA film rolls from OwnLikes offer distinct advantages:

- Biodegradability: Unlike OPP and PET films, which persist in the environment for centuries, PLA films degrade naturally.

- Antistatic Properties: Reduces dust and particle attraction, ideal for electronic component packaging.

- High Transparency and Color Reproduction: Provides superior visual appeal for product presentation.

- Strong Rupture Resistance: Withstands handling and transportation stresses, ensuring product protection.

- High Barrier Properties: Protects contents from moisture, oxygen, and other environmental factors.

- Odorless and Non-Toxic: Safe for food contact and does not emit harmful fumes upon combustion.

- Ease of Tearing: Convenient for both consumers and manufacturers, meeting special packaging needs.

Environmental Impact: The Residue After Degradation

After complete degradation, OwnLikes’ PLA film rolls leave behind harmless substances such as protein and glucose. Imagine a world where plastics no longer litter our oceans and waterways. Where sea creatures swim freely without the threat of ingesting or becoming entangled in plastic waste. PLA films contribute to this vision by eliminating the long-lasting environmental hazards of traditional plastics.

Recycling Potential: A Step Towards a Circular Economy

OwnLikes’ PLA film rolls support the circular economy by being fully recyclable. When regenerated, the proportion of biodegradable cellulose materials in finished products does not exceed 20%, eliminating the need for separation processing. These films can be recycled alongside paper waste, further reducing landfill contributions and advancing recycling efforts.

Conclusion: A Sustainable Future with PLA Film Rolls

As industries across the globe pivot towards sustainability, the demand for eco-friendly packaging solutions has never been greater. OwnLikes, through its innovative and sustainable PLA film roll materials, provides businesses with the tools they need to meet this demand while maintaining product integrity and branding excellence.

The journey toward a plastic-free future begins with responsible choices today. By adopting PLA film rolls, businesses can align themselves with the growing consumer expectation for sustainability, contributing to a cleaner, greener, and more biodiverse planet. With comprehensive customization options, robust performance characteristics, and full compliance with global environmental standards, OwnLikes’ PLA film rolls offer an unmatched solution for the future of packaging. Together, we can redefine packaging, transform industries, and create a healthier home for generations to come.

We offer comprehensive technical support, including free professional labeling solutions, advice on label materials and adhesive selection, as well as online/offline assistance from professional software and hardware engineers. Service email: andy@ownlikes.cn. In pre-sales, we leverage our extensive experience in specialty labeling projects to provide clients with the most suitable hardware solutions. Additionally, all our label barcode printers and scanners come with a three-year free warranty, demonstrating our confidence in our products.