Transfer AB film finished product structure and self-adhesive material are sandwich principle, two layers of material sandwich glue, and the principle of use is different: self-adhesive is the base paper for the waste layer, and the crystal label base paper and transfer film are waste layer.

Product Review:What is Transfer AB film

Two kinds of Transfer printing process, matching the corresponding material, there is a direct spray process of glue selection, here talk about AB film process AB film material

Due to the high heat of the product, the market is large, many domestic material coating factories began to study AB film, and in fact, the quality of the crystal standard material is uneven, how to choose a beautiful cheap, strong adhesion AB film, is the key to making the perfect pattern.

AB film finished product structure and self-adhesive material are sandwich principle, two layers of material sandwich glue, and the principle of use is different: self-adhesive is the base paper for the waste layer, and the crystal label base paper and transfer film are waste layer.

Therefore, many manufacturers in order to pursue profits and the bottom paper and transfer film are used cheap materials, we need to master the following knowledge points:

Glue

Glue determines whether the finished product will roll, crack, wire drawing, overflow and other phenomena, before printing the finished product, can not distinguish the good or bad glue, in addition to buy back to test, the only choice is not to covet cheap, try to choose mature market verified products, it is best to look at the supplier's finished product, try and step by step batch procurement.

Release Paper

The key to determining the difficulty of transferring crystal labels is in addition to glue and backing paper, so the following conditions should be met when selecting:

1. The base paper is made of high quality Singer release paper

2, dense texture, uniform, has a good internal strength and light transmission

3, with high temperature, moisture, oil and other functions

4, can be firmly combined with glue to stick the pattern, strong adhesion, easy to peel off when pasted

Transfer Membrane

The transfer film is also the B film, that is, the layer of transparent waste film covered in A film that transfers the pattern of the print layer out, because it is a waste material, many people use the sealing film on the hot mounting machine, which is also the reason for the instability of quality.

The thickness and high temperature resistance of the film are very important, determining whether the finished product is curled when placed, or the phenomenon that the film does not fall off (not completely separated from the pattern) after transfer.

After understanding the precautions, it will avoid causing quality problems on the production, that is, sharpening the knife does not mistakenly cut wood. The specific process flow is roughly the same, the core technology is on the selection of materials, reasonable selection of materials, to avoid trial and error costs.

The characteristics of Transfer AB film

1. High transparency, thick, with glue, hard, scratch resistance, high temperature resistance, new over time, no fading, no yellow, anti-ultraviolet.

2. Environmental protection, waterproof and wear-resistant, bright color, good 3D texture, simple operation, easy to paste, can paste any material (except fabric).

Transfer AB film production process

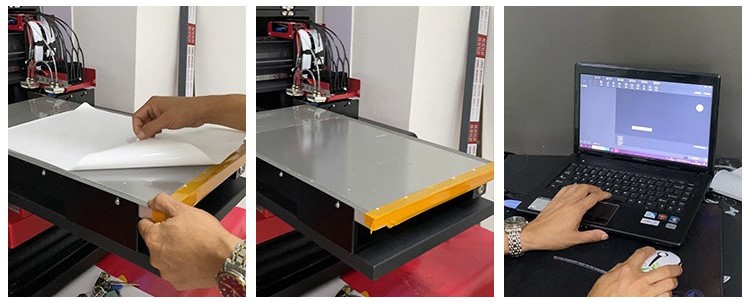

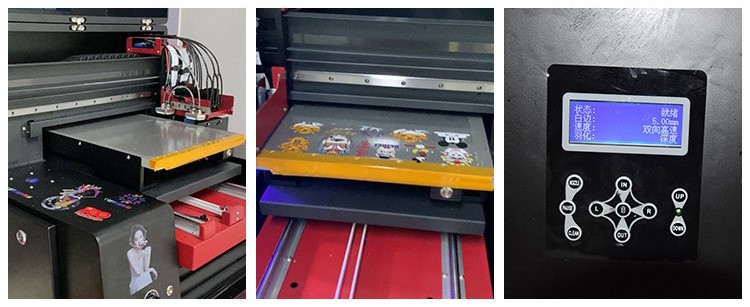

1. Prepare the UV printer, first put the film A film on the printing plate, open the air suction platform, tear off the protective film of the A film, select the ink, to choose UV soft ink (white ink), UV color ink, UV gloss oil (neutral).

2. The order of printing is to print white ink - color ink - gloss oil, and finally use UV light to cure the printed pattern.

3. How to use the printing film and transfer film, first place the A film of the film on the plate of the printer, and then tear off the white isolation paper.

4. Use tape to lay A film on the plate, so that the edge does not tilt up, to prevent scratching the printer nozzle.

5. After the printing is completed, the transfer film is coated with a hot laminating machine. It should be noted that the transfer film is coated with a matt surface inside.

About the crystal label AB film, the questions you want to consult can be found here

Q: What is the size of this AB film?

A :A3 size (30*42 cm)

Q: How does this membrane work?

A :UV printer print directly, hot meter machine directly apply B film Q: What material can be printed out of the crystal label? A: You can paste almost any material except fabric

Q: What printer does AB film need to print?

A: Ordinary UV printer can be (need to bring light oil can be) Q: How about the viscosity of crystal label material? Do you need glue? Answer: The fastness is many times higher than screen printing, no glue, no waste

Q: Is it resistant to high temperatures?

A: Resistance to high temperature of 120 degrees

Q: What is the material made of?

A: Polymer materials

Q: How long will the materials be stored?

A: One year

At present, Transfer sticker have been widely used in packaging, graphics, printing, gift customization, wine and tea and other industries, especially small batch customization, more and more business consumers choose a Transfer sticker that can be printed. Transfer mark printing process is to directly print A film directly white ink, color ink, glossy oil printing into patterns, trademarks, etc., so it has more scratch resistant than traditional stickers, and waterproof, sunscreen and high temperature, outstanding performance.

If you have any questions about our head Stickers material products, please feel free to contact us.

Customer Feedback(1)

I used the Transfer AB Film for a vinyl decal project, and it made the process really easy. The film picks up the design cleanly and releases it smoothly onto the surface. It sticks well during transfer but doesn’t leave any residue—super helpful for clean, accurate applications.