PVC(Polyvinyl ) self-adhesive sticker materials have two kinds of soft and hard, durability, tear resistance, softness, good chemical corrosion resistance, and many applications in electronics, machinery and batteries, outdoor pasting. However, the temperature resistance and tensile resistance are PVC car sticker material, suitable for the identification of non-flat surface articles. Self-adhesive stickers, self-adhesive label stickers based on PVC film, mainly used for decorative decals on cars and motorcycles, logo words on trademark Windows, reflective films on highways, marks on containers, etc. Paper and film based self-adhesive label stickers, according to the scope of application is divided into basic label and variable information label. Body stickers are used to paste on the body of the car, this kind of spray painting adhesive, anti-sunlight.

Product Review:PVC has non-flammability, high strength, resistance to climate change and excellent geometric stability, and has strong resistance to oxidants, reducing agents and strong acids. In addition, because of its good flexibility, shrinkage and light permeability, processing and labeling performance is good, chemical corrosion resistance, strong and durable, so suitable for long-term outdoor use.

However, the thermal stability and light resistance of PVC is poor, and it can begin to decompose and release hydrogen chloride (HCl) gas above 140 ° C, which is not conducive to environmental protection (the actual production often adds alkaline stabilizer and HCl to inhibit its catalytic cracking reaction). And in the manufacturing process, plasticizer, anti-aging agent and other toxic auxiliary materials are added to enhance its heat resistance, toughness, ductility, etc., so its products are generally not stored food and drugs. In addition, the degradation of PVC label materials is poor, which has a negative impact on environmental protection.

PVC car sticker material, suitable for the identification of non-flat surface articles. Self-adhesive stickers, self-adhesive label stickers based on PVC film, mainly used for decorative decals on cars and motorcycles, logo words on trademark Windows, reflective films on highways, marks on containers, etc. Paper and film based self-adhesive label stickers, according to the scope of application is divided into basic label and variable information label. Body stickers are used to paste on the body of the car, this kind of spray painting adhesive, anti-sunlight.

Car sticker, short for body sticker; Mainly used in body advertising, poster advertising, window advertising, advertising board posters.... It is mainly composed of white opaque PVC+ acrylic adhesive + base paper, which can be used for solvent, weak solvent machine (domestic like oil machine, or inkjet machine); The advantages and disadvantages of general car sticker materials depend on the use of raw materials by manufacturers; Domestic PVC film is generally rolled grade, use to 1 year or even shorter will shrink; cast vinyl produced abroad (France, Germany, Sweden, Finland, Turkey have manufacturers), the production cost is the same as that of domestic rolled vinyl, but the use of the process basically does not shrink, the minimum service life of more than 3 years; Divided from the performance of glue, mainly movable glue and permanent glue (there is no semi-movable glue, manufacturers do not do movable glue to say so); Generally used for the body advertising series car stickers, are required glue can be moved; Why, you ask? Have you ever seen the tape stuck on the glass for a period of time, after removing the tape, the glue remains on the glass, and the black can not be cleaned off?)

Commonly Used Car Sticker Material

Because the body sticker needs to be used outdoors, it is required to be able to protect against sun and rain, so the material is usually PVC or PET.

PVC products have chemical stability and strong resistance to oxidants, reducing agents and strong acids. However, it can be corroded by concentrated oxidizing acids such as concentrated sulfuric acid and concentrated nitric acid, and it is not suitable for contact with aromatic hydrocarbons and chlorinated hydrocarbons.

PVC has the advantages of flame resistance and self-extinguishing, wear resistance, noise and shock absorption, high strength, good electrical insulation, low price and wide source of materials, good airtight performance, etc.

The disadvantage of PVC is poor thermal stability and easy aging by light, heat and oxygen. The long-term use temperature of most PVC plastic products should not exceed 55 ° C, but the long-term use temperature of special formula PVC plastic can reach 90 ° C.

PVC has non-flammability, high strength, resistance to climate change and excellent geometric stability, and has strong resistance to oxidants, reducing agents and strong acids. In addition, because of its good flexibility, shrinkage and light permeability, processing and labeling performance is good, chemical corrosion resistance, strong and durable, so suitable for long-term outdoor use.

PET polyester film is based on polyethylene terephthalate as raw material, PET has excellent physical and mechanical properties in a wide temperature range, long-term use temperature up to 120℃, excellent electrical insulation, even at high temperature and high frequency, its electrical properties are still good, but poor corona resistance, anti-toxic, climate resistance, chemical stability, creep, fatigue resistance, The friction resistance and dimensional stability are very good. Low water absorption, resistance to weak acids and organic solvents, but not heat resistant to water immersion, not alkali resistance.

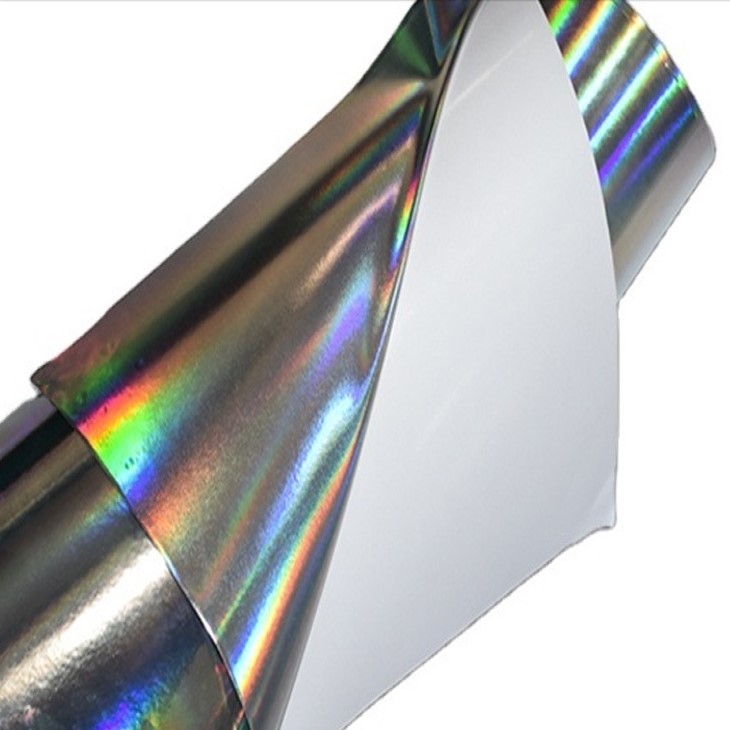

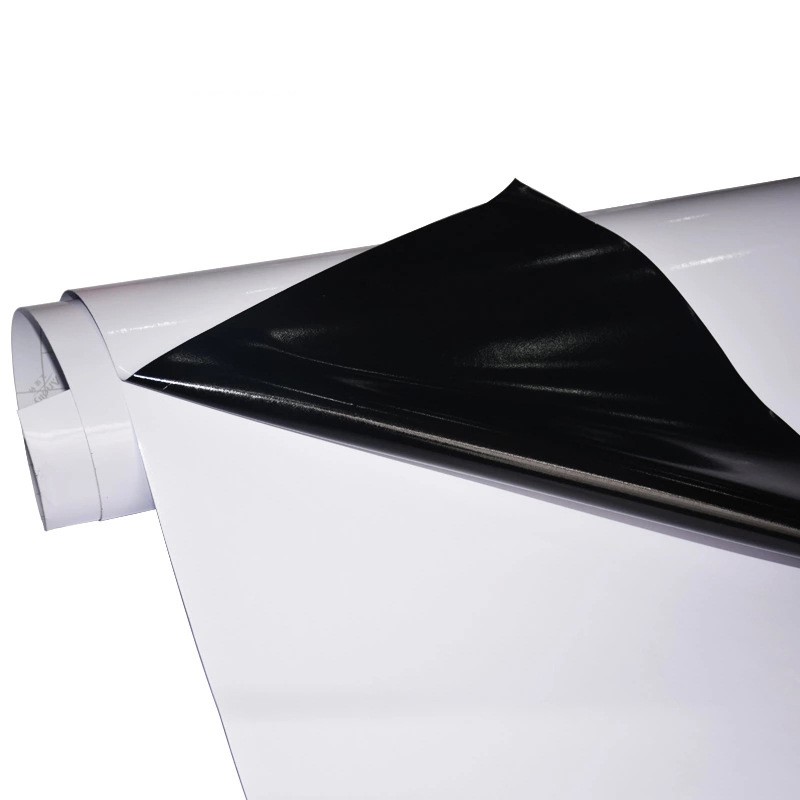

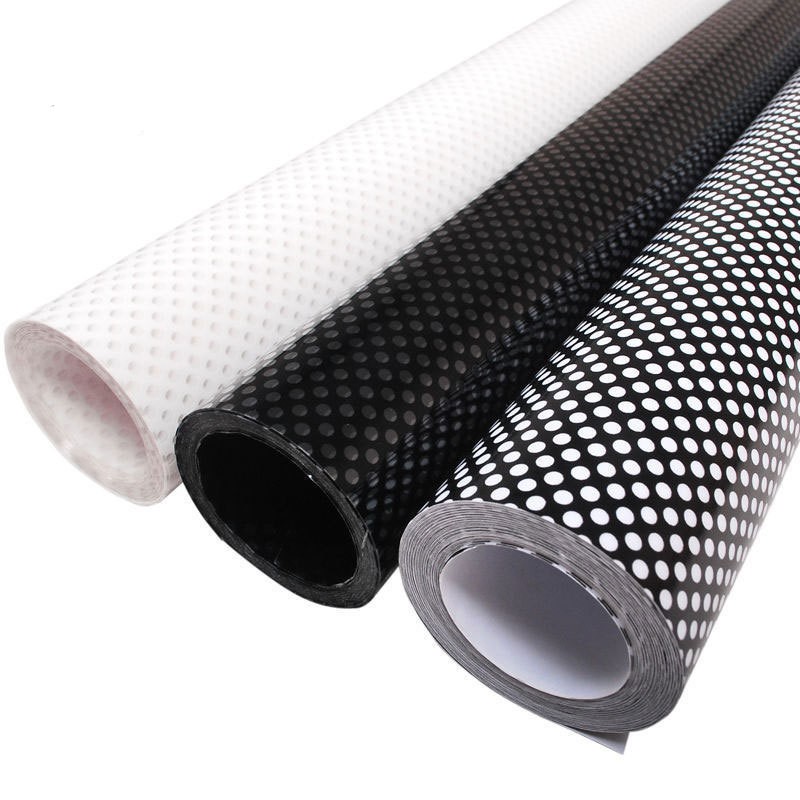

Common Body PVC Car Sticker Material:

|

|

|

| Conventional Car Sticker Material | Transparent Car Sticker Material | White Adhesive Car Sticker Material |

|

|

|

| Black Adhesive Car Sticker material | Grey Glue Car Sticker Material | Single Transparent Sticker Material |

Installation Procedure

Tools: Transfer film, rag, scraper or credit card

1. Clean the body and evenly sprinkle water on the body parts to be pasted - to reduce the viscosity of the sticker and facilitate the adjustment of the position;

2. Determine the location of the tape. Slowly stick on one side, gently scrape with a tool, and uncover the transfer film (translucent paper);

3. When you encounter the door handle or wipe strip, cut the material and wrap it in according to the situation;

4. Adjust properly, after determining the general position of the figure, forcibly scrape off the water and bubbles repeatedly. The transparent transfer film was removed;

5. Make a cut on the door and seam of the car with a utility knife and wrap it inwards;

6. Do not let the car sticker and the body have any separation or protrusion;

7. Try to let the moisture in the car stickers dry thoroughly, and can be moderately heated and dried if conditions exist. Wait a day or two to wash the car, depending on the weather.

Bubble Resolution:

1. The safest way is to make a small diagonal cut from one side of the bubble with a utility knife, and then smooth it with a scraper and a baking gun.

2. Tear it off in half and then slowly put it on.

3. Prick the bubble with a needle and press flat.

4 Dry paste method, there will be inevitable bubbles, do not panic ~ small two I will tell you the solution: First squeeze the small bubble with your fingers, try to squeeze a piece to go. Then use a needle, or

The head of the utility knife, gently poke, a finger press, the bubble is gone. There are tiny bubbles that you can ignore. Under the sun for 1-2 days, through the increase in temperature, the air inside will overflow from the material! Absolute flatness

If you have any questions about our head Stickers material products, please feel free to contact us.

Customer Feedback(1)

I recently used the Black PVC Car Sticker Material for a custom project on my vehicle, and I'm very pleased with the results. The material is tough and has a nice matte finish that gives it a sleek, professional look. It’s easy to apply and sticks securely without any bubbles or peeling. Great quality for anyone looking to add a personal touch to their car!