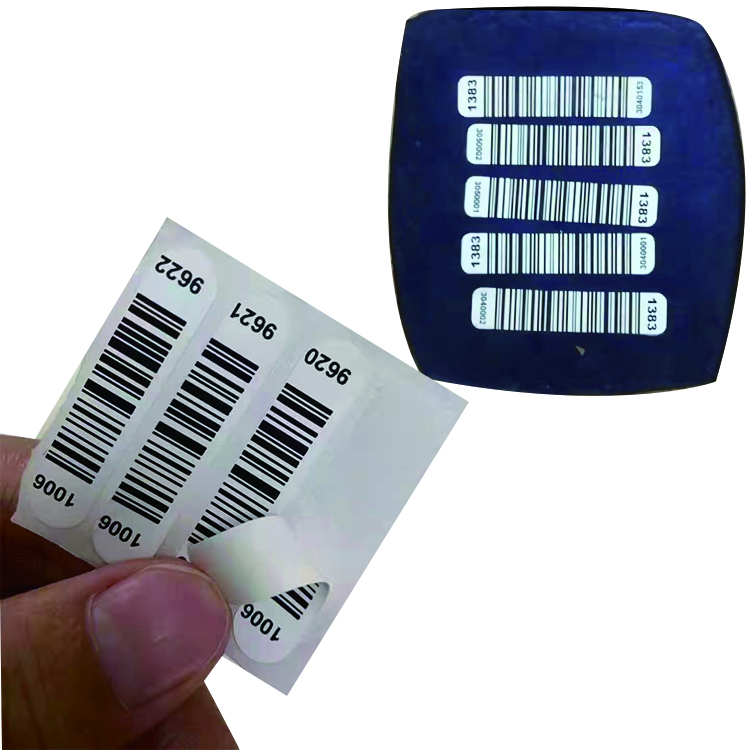

OwnLikes is specifically designed for all-steel tire barcode and tire number etching applications, and consists of a permanent rubber-based glue that is resistant to high temperatures and vulcanized with the tire for the entire life cycle of the tire. Features: • Excellent high temperature stability, withstand the heat and pressure of the tire when it is treated with high temperature and sulfur (up to 210℃) • Excellent durability and wear resistance • Excellent chemical resistance: strong water resistance, acid resistance, salt, alkali, most oil stains, oil and low-fat solvents, adhesives can penetrate into the concave surface, firmly combined with the tire surface penetration softener, when the car in the running bar code will not fall off, at the same time, artificial forced peeling will not destroy the tire surface rubber • Excellent barcode/heat transfer printing effect, with VR-30 carbon belt, to ensure 100% accurate reading and scanning on the high-speed transmission line before and after vulcanization. • Excellent adhesion: When the tire is removed from the mold, strong flexibility to withstand tire deformation

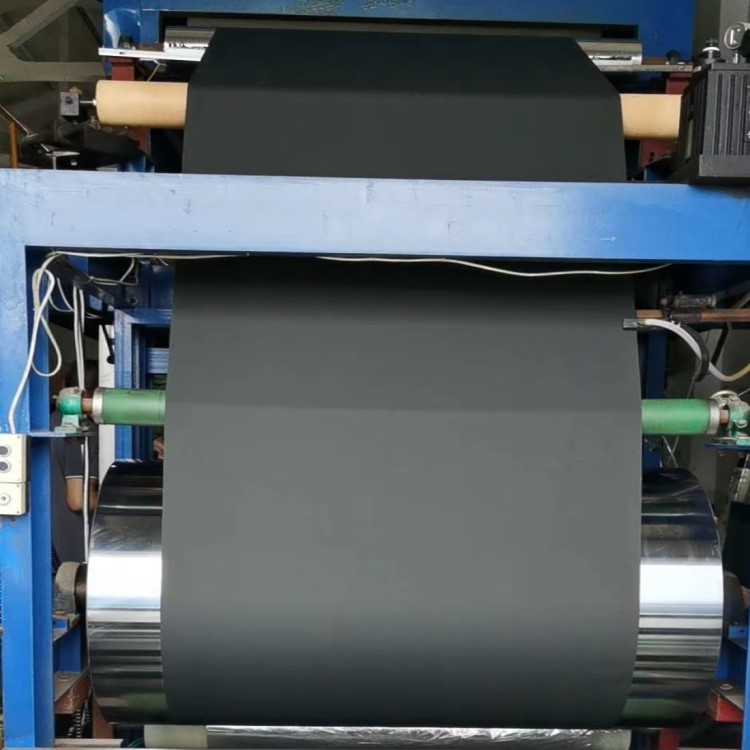

Vulcanization Purpose:

Through external shear, high temperature promotes the chain molecules in the rubber to cross-link into a network molecule, strengthening its tensile force, hardness, aging, elasticity and other properties to make it more valuable. In the vulcanizer, the tire will be at a high temperature of more than 145 degrees Celsius, depending on the size, the vulcanization time will vary to form the final shape and tread pattern. A hot die shapes and hardens the tire. When the machine is turned on, the tire will roll out of the mold and be sent through a long conveyor belt for final inspection.

The significance of vulcanization label in tire industry:

After the tire is formed, the barcode label is affixed to it and vulcanized so that it is kept throughout the life of the tire, and the production date, installation date and service date of the tire are fed back at any time, thus providing reliable raw data for quality assessment.

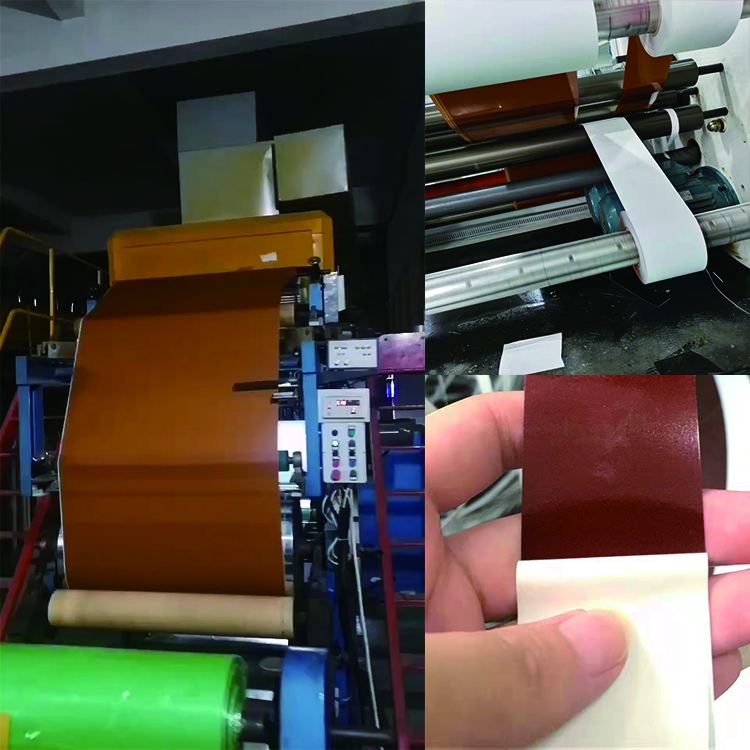

Product Features:

• Excellent high temperature stability, withstand the heat and pressure of the tire when it is treated with high temperature and sulfur (up to 210℃)

• Excellent durability and wear resistance

• Excellent chemical resistance: strong water resistance, acid resistance, salt, alkali, most oil stains, oil and low-fat solvents, adhesives can penetrate into the concave surface, firmly combined with the tire surface penetration softener, when the car in the running bar code will not fall off, at the same time, artificial forced peeling will not destroy the tire surface rubber

• Excellent barcode/heat transfer printing effect, combined with the west carbon belt, to ensure 100% accurate reading and scanning on the high-speed transfer line before and after vulcanization.

• Excellent adhesion: When the tire is removed from the mold, strong flexibility to withstand tire deformation

Order Size:

Reference Size: 530*500m (coil), 30mm*6mm 38mm*8mm 40mmX10mm and other specifications of die cut and prefabricated bar code coil

Certification: Rohs, halogen free

L/T: 10 days, according to the actual customization requirements

Regular Product Information:

| P/N | Materials | Thickness μm | Release Paper | Printing Mode | Temperature Resistance | Ribbon | Peculiarity |

| VL-75 | 75μPET | 100±10 | PET | Thermal transfer/Printing | 200℃ | VR-35 | Suitable for motorcycle tires |

| VL-100 | 100μPET | 125±10 | PET | Thermal transfer/Printing | 200℃ | VR-35 | Be common |

| VL-125 | 125μPET | 155±10 | PET | Thermal transfer/Printing | 200℃ | VR-35 | Be common |

| VL-250 | 250μPET | 270±10 | PET | Thermal transfer/Printing | 200℃ | VR-30 | Laser etching |

| VL-H50 | 50μPI | 70±10μ | PET | Thermal transfer/Printing | 200℃ | VR-30 | Vulcanized capsule |

Alternative Product Information:

| P/N | Materials | Adhesive | Release Paper | Printing Mode | Temperature Resistance | Ribbon | Labeling method | Fungible |

| VL-75 | 75μPET | 100±10 | Glazin paper | Thermal Transfer | 200℃ | VR-35 | Manual/Automatic | Kuramoto |

| VL-100 | 100μPET | 125±10 | PET Film Base | Thermal Transfer | 200℃ | VR-35 | Manual/Automatic | Computype |

| VL-125 | 125μPET | 155±10 | PET Film Base | Thermal Transfer | 200℃ | VR-35 | Manual/Automatic | United States /DATA 2 Hochang, Taiwan |

| VL-250 | 250μPET | 270±10 | PET Film Base | Thermal Transfer | 200℃ | VR-30 | Manual/Automatic | Nitto, Japan |

| VL-H50 | 50μPI | 70±10μ | Glazin paper | Thermal Transfer | 200℃ | VR-30 | Manual/Automatic | Japanese Linderaceae |

The combination of barcode machine printing and scanning gun recommended by OwnLikes constitutes a complete tire quality traceability system, providing the perfect tire vulcanization process tracking management solution the curing time of the manufacturers is different. Affected by the size, pattern type, vulcanization temperature, compound formula, tire structure and other factors, semi-steel car tires are generally 9-30 Minutes, the whole steel is generally 45-60 minutes, according to the size of the tire and vulcanization process to decide, please be sure that the customer to do field testing.

The specific price is determined according to the size of the label, the pattern, and the quantity ordered. Please consult your OwnLikes local sales and technical support team.

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.