A durable polyimide film label with a special coating specifically designed for high temperature applications.

Product features and benefits

This product has excellent tear resistance, high temperature resistance, dimensional stability, chemical corrosion resistance. Specially designed surface coating with suitable

The resin based carbon strip is used, showing excellent wear resistance, scratch resistance, UV resistance, high temperature resistance and solvent resistance, suitable for use

Tracking tag application in one or two reflow processes. The use of 25 micron polyimide films can meet the same application requirements

It can also save the cost of use by the end user.

Application and use

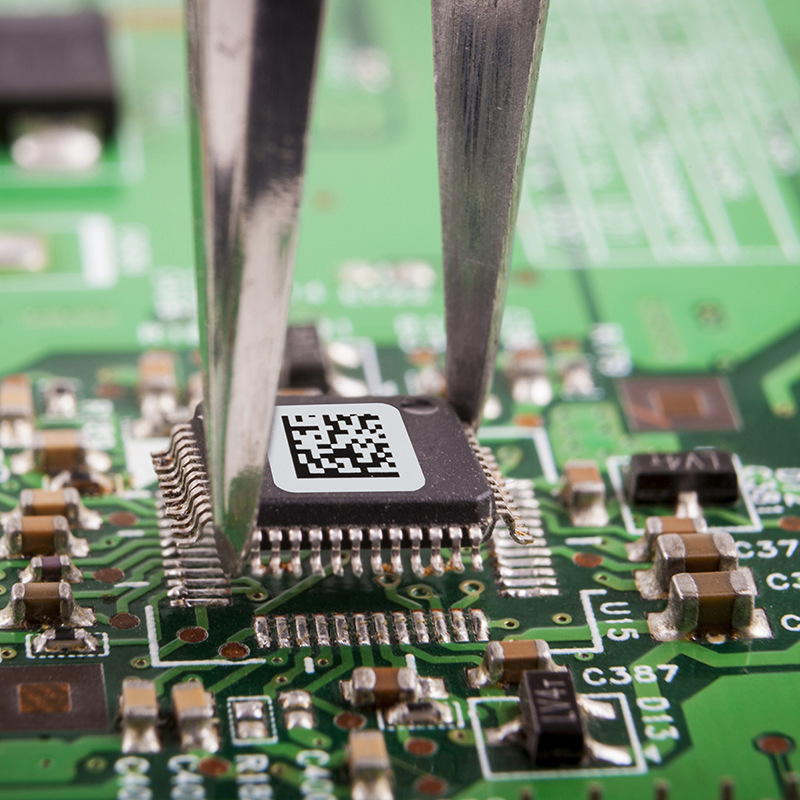

Designed for lead-free high-temperature welding process applications in the printed circuit board (PCB) industry, but also suitable for other applications

Applications requiring high temperature and solvent resistance, such as the LED industry, automotive industry, aerospace industry, medical and manufacturing

Let's wait. The product is matched with a suitable resin-based carbon tape, which can be attached to the front or back of the circuit board and can withstand surface mounters

The application of art is required, but testing before use is a must.

Printing and processing

High performance surface coatings are specifically designed for heat transfer printing and are also suitable for most conventional printing methods, but pre-print testing is

It is necessary. Our materials can be used with a wide range of high performance industrial heat transfer printers and resin-based carbon strips for heat transfer

The choice of printing machine and carbon strip will affect the overall printing quality and environmental tolerance, so we recommend that you must be specific before use

Order the printer and carbon strip for testing. For more details, please see the "Appendix" below or contact us.

This product can be used for high-speed die-cutting and waste removal on most standard rotary presses. A sharp die-cutting tool with high hardness is recommended.

Especially in the flat die-cutting mode.

Automatic labeling applications are not recommended.

Product certification and regulations

UL: This product is UL969 certified. UL Certification number: MH20558, please visit UL website for details.

RoHS: In accordance with the EU RoHS Directive 2002/95/EC.

Halogen-free test: Not detected, test refer to EN14582:2007.

Storage life

It can be stored for one year at a temperature of 23±2 C and relative humidity of 50±5%.

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.