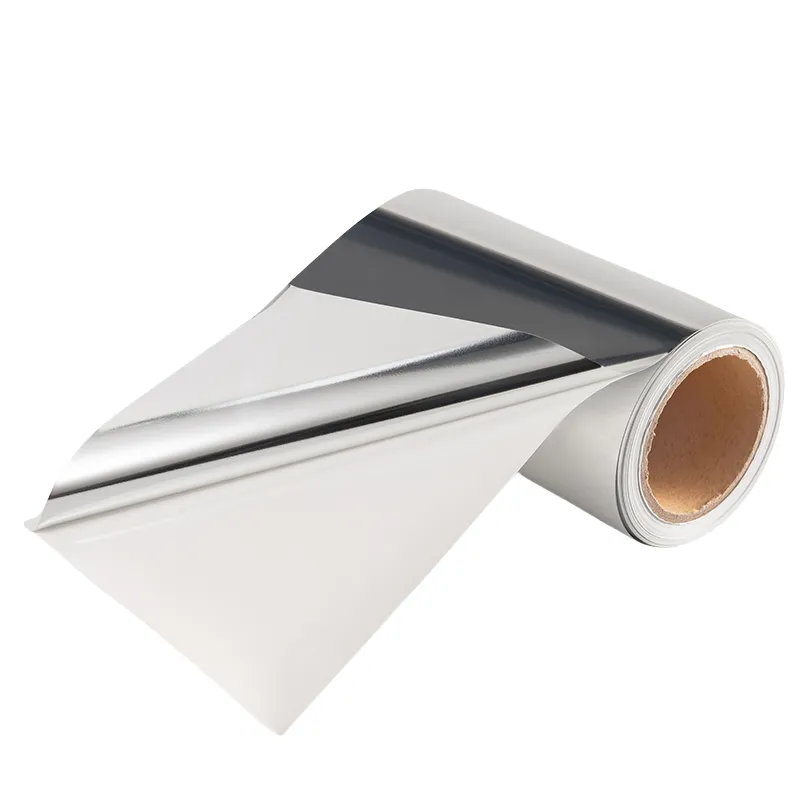

Flexographic glossy silver sticker label material is a glossy silver PET sticker specially designed for high-end packaging and brand logos. It combines an environmentally friendly flexographic printing process with a gold-plated metalized PET substrate to present a mirror-like metallic luster effect. The balanced design of FDA certified food-grade materials and industrial-grade weather resistance meets the dual demands for texture and functionality in multiple fields such as fast-moving consumer goods, electronic products, and luxury goods.

Product Review:Flexographic printing polyester sticker material

High-performance, durable and environmentally friendly sticker solutions

Product Overview

Flexographic glossy silver sticker label material is a glossy silver PET sticker specially designed for high-end packaging and brand logos. It combines an environmentally friendly flexographic printing process with a gold-plated metalized PET substrate to present a mirror-like metallic luster effect. The balanced design of FDA certified food-grade materials and industrial-grade weather resistance meets the dual demands for texture and functionality in multiple fields such as fast-moving consumer goods, electronic products, and luxury goods.

Core Characteristics

The special silver plating process creates a mirror-like lustrous surface, presenting a luxurious metallic texture. It has an outstanding reflection effect under strong light, instantly catching consumers' eyes and enhancing the competitiveness of shelf display.

The surface is smooth and flat, with a fine touch. After printing, the color saturation is high, enhancing the appearance grade of the product.

High and low temperature resistance: It can be stably used in an environment ranging from -40℃ to 150℃, and is suitable for various scenarios such as cold storage and high-temperature sterilization.

Chemical corrosion resistance: Resistant to common chemicals such as oils, solvents, weak acids and weak alkalis, suitable for industrial and laboratory environments.

Tear resistance and wear resistance: The high-strength polyester base material can resist external force damage such as transportation and friction, extending the service life of the label.

Surface optimized coating: Special coating treatment enhances ink adhesion, compatible with water-based, UV and solvent-based flexographic inks, ensuring rich colors and fine patterns.

Fast drying and low energy consumption: Combined with the efficient production rhythm of flexographic printing, it reduces energy consumption and lowers the overall cost.

Compliant with RoHS/REACH standards: No harmful substances added, suitable for direct contact packaging of food, medicine, etc.

Customizable eco-friendly adhesives: Offer permanent, removable or low-temperature resistant adhesive options to meet different application requirements.

Diversified surface treatments: Matte, glossy or anti-static coatings are available to meet the requirements of anti-glare, high gloss or protection of electronic components.

Laminating and laminated: Supports integration with anti-counterfeiting technologies (such as holographic films) to enhance brand security and visual appeal.

Typical application scenarios

Food and beverages: Cold chain labels, bottle labels, canned food labels (resistant to condensation and freezing).

Industry and Chemical Engineering: Equipment nameplates, pipe identification, chemical warning labels.

Electronic products: Circuit board identification, high-temperature resistant electronic component labels.

Logistics and retail: Outdoor storage labels, anti-counterfeiting and traceability labels, high-end product tags.

Product structure

Surface material: High transparency/white polyester film (thickness 25-100μm available).

Coating: Functional coating for optimized printability (UV-resistant or scratch-resistant treatment is optional).

Adhesive: Acrylic pressure-sensitive adhesive (permanent type/removable type), peel force range 300-1200g/25mm.

Base paper: White Glassine release paper (weight 60-120g/㎡), easy to die-cut and resistant to wrinkling.

Technical advantage

Printing efficiency: Reduce printing downtime, lower the scrap rate, and be compatible with high-speed rotary printing machines.

Cost-effectiveness: Long-life labels reduce the frequency of replacement and save maintenance costs.

Customized services: Support personalized customization of size, thickness, adhesive and printing effect.

Specification parameters

Standard width: 200mm-1200mm (slitting available).

Core diameter: 76mm/152mm.

Storage conditions: Temperature 20-30℃, humidity 40-60%, keep away from light and flat.

Reasons for selection

Flexographic printing polyester label materials take technological innovation as the core, combine environmental protection concepts with industrial demands, and provide global customers with high cost-performance and high value-added label solutions. Whether it is the reliability in extreme environments or the exquisite presentation of brand visuals, both can exceed expectations.

Consult now to get samples and customized solutions!

If you have any questions about our head Stickers material products, please feel free to contact us.

Customer Feedback(1)

Used the Flexographic Glossy Silver Sticker Label Material and it looks sharp! The shiny finish gives it a premium feel, and it prints great. Makes my labels look way more professional.