Water soluble embroidery stabilizer sticker paper that can be laser-printed is a highly efficient embroidery auxiliary material that combines multiple functions, specially designed for modern digital embroidery techniques. It integrates three major features: laser printing compatibility, water-soluble support, and self-adhesive bonding, significantly simplifying the embroidery process. It is suitable for complex embroidery designs in fields such as clothing, home furnishings, and handicrafts.

Product Review:Our embroidery stickers are made of high-quality water-soluble stabilizers, which are easily soluble in water, ensuring that the embroidery items are clean and free of residue. The embroidery stickers feature a self-adhesive design, allowing them to be easily adhered to fabrics without the need for tracking or transferring designs. The various style embroidery stabilizers that can be mixed and matched allow you to create unique and exquisite designs on your fabrics using a variety of embroidery stitches and colored threads. They add exquisite and vivid colors to your creations, making them an excellent choice for both beginners and experienced artisans. They can be used to practice your sewing skills and also serve as an interesting thing

Product Overview

Water soluble embroidery stabilizer sticker paper that can be laser-printed is a highly efficient embroidery auxiliary material that combines multiple functions, specially designed for modern digital embroidery techniques. It integrates three major features: laser printing compatibility, water-soluble support, and self-adhesive bonding, significantly simplifying the embroidery process. It is suitable for complex embroidery designs in fields such as clothing, home furnishings, and handicrafts.

Core Features Advantages

Patterns can be directly printed through a laser printer to accurately present design details (please confirm the applicable model of the product to avoid high-temperature damage to the material).

It eliminates the traditional transfer printing step, reduces errors, and is especially suitable for fine patterns or embroidery projects that require precise positioning.

After the embroidery is completed, soak the fabric in warm water (usually 40-60℃). The stabilizing layer will dissolve quickly without leaving any residue, avoiding damage to the embroidery thread caused by manual tearing.

Suitable for hollowed-out embroidery, thin fabrics or high-density designs, it provides temporary support while maintaining the softness of the finished product.

The back is pre-coated with eco-friendly removable adhesive, which can be easily adhered to the fabric surface without the need for additional fixing tools (such as pins or tape).

Prevent the fabric from shifting from the stabilizer during the embroidery process, especially suitable for curved or elastic fabrics.

Environmental Protection and Safety

Water-soluble materials are biodegradable and meet environmental protection standards. The self-adhesive has no toxic residue and is suitable for children's clothing and close-fitting fabrics.

Typical Application Scenarios

Print complex geometric shapes, text or positioning marks to achieve a 1:1 reproduction of embroidery and design.

When used in combination, it can be dissolved layer by layer and supports a 3D stereoscopic embroidery effect.

Quickly print personalized patterns to enhance customization efficiency (such as corporate logos and wedding souvenirs).

Fabrics such as silk and chiffon that are prone to deformation can be reinforced by stabilizers to prevent pulling and damage during the embroidery process.

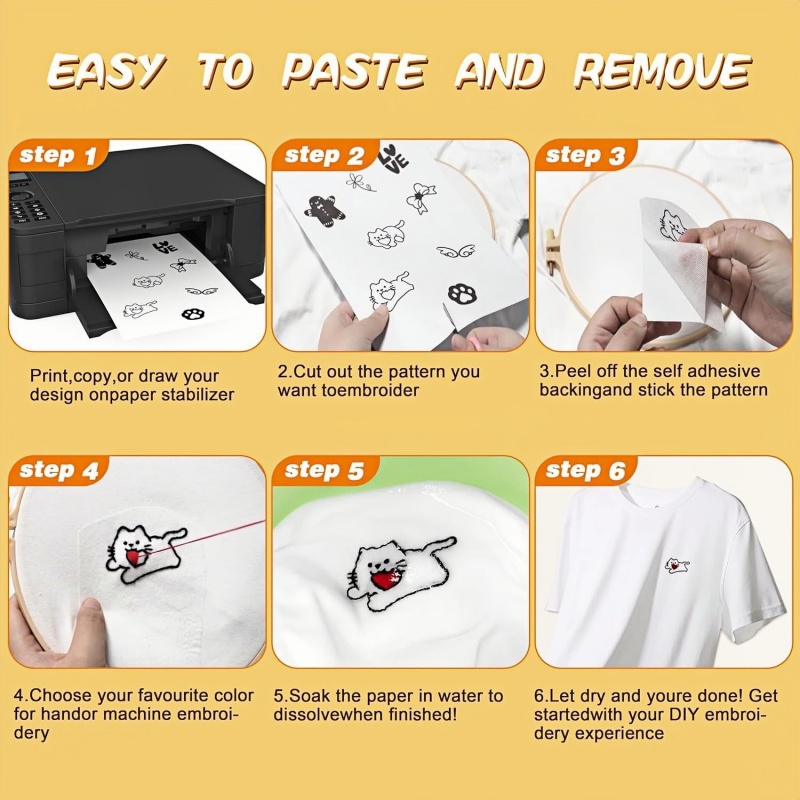

Step-by-step Guide for Use

Mirror the design drawing in the drawing software (to meet the printing requirements of the back of the embroidery).

Load the stabilizer into the laser printer, print and cut as needed.

Tear off the backing paper, stick the patterned surface onto the fabric, and fix it in the embroidery frame.

After completing the embroidery, soak it in cold water for 10 to 15 minutes until the stabilizer is completely dissolved, and then let it dry naturally.

Precautions

Printer Settings: Select the toner residue-free mode to prevent the adhesive layer from melting at high temperatures.

Water temperature control: If the water temperature is too high, it may cause glue stains to remain; if it is too low, the dissolution will be slow.

Fabric testing: It is recommended to test compatibility on small pieces of fabric for the first use.

Storage conditions: Store in a dark and moisture-proof place to prevent the rubber surface from failing or the material from deforming.

DIY Project

Easy to use: Just cut and peel off the floral pattern backing from a lightweight stabilizer, stick the pattern onto fabric or clothing, and then start embroidering. After completion, rinse or soak in warm water to dissolve the adhesive. After drying, you will obtain exquisite flower patterns

Wide Application

The stick and pin stabilizer can be widely used in handbags, shirts, hats, canvas shoes, aprons, towels, cushions, tablecloths, linen and other items. They can also be used to repair damaged areas or holes, adding a unique touch to your clothes. They are meaningful gifts for the people you love.

Market Positioning and Trends

With the rise of personalized customization and sustainable processes, the application scenarios of such smart composite materials continue to expand. In the future, it may be combined with technologies such as AR positioning and conductive embroidery to further promote the digital upgrade of the textile industry.

If you have any questions about our head Stickers material products, please feel free to contact us.

Customer Feedback(1)

For anyone looking to add a touch of versatility, the Laser Printer Water Soluble Cloth Sticker Paper is a great choice. It’s easy to work with, and the texture really gives a premium feel to your creations.