Black Polyimide high-temperature resistant sticker label material is specially designed for harsh industrial environments. It uses high-purity black polyimide film substrate and combines thermal transfer printing compatible coating technology to create a special label material that integrates high-temperature resistance, chemical corrosion resistance and excellent mechanical strength. It is applicable to scenarios with extremely high requirements for the durability of signs in fields such as electronic manufacturing, automotive industry, aerospace, etc.

Product Review:Product Overview

Black Polyimide high-temperature resistant sticker label material is specially designed for harsh industrial environments. It uses high-purity black polyimide film substrate and combines thermal transfer printing compatible coating technology to create a special label material that integrates high-temperature resistance, chemical corrosion resistance and excellent mechanical strength. It is applicable to scenarios with extremely high requirements for the durability of signs in fields such as electronic manufacturing, automotive industry, aerospace, etc.

|

|

|

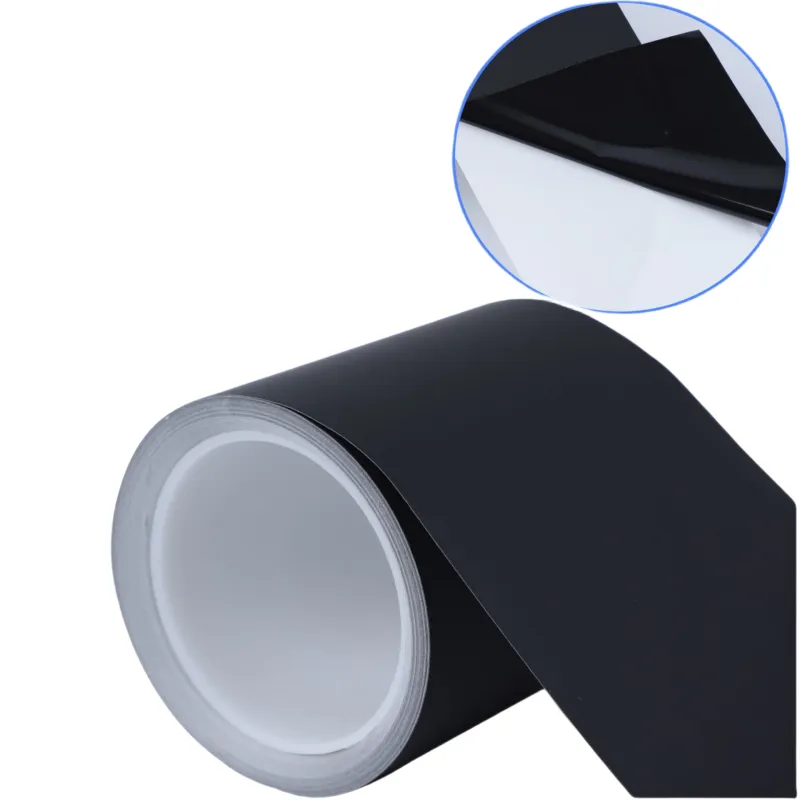

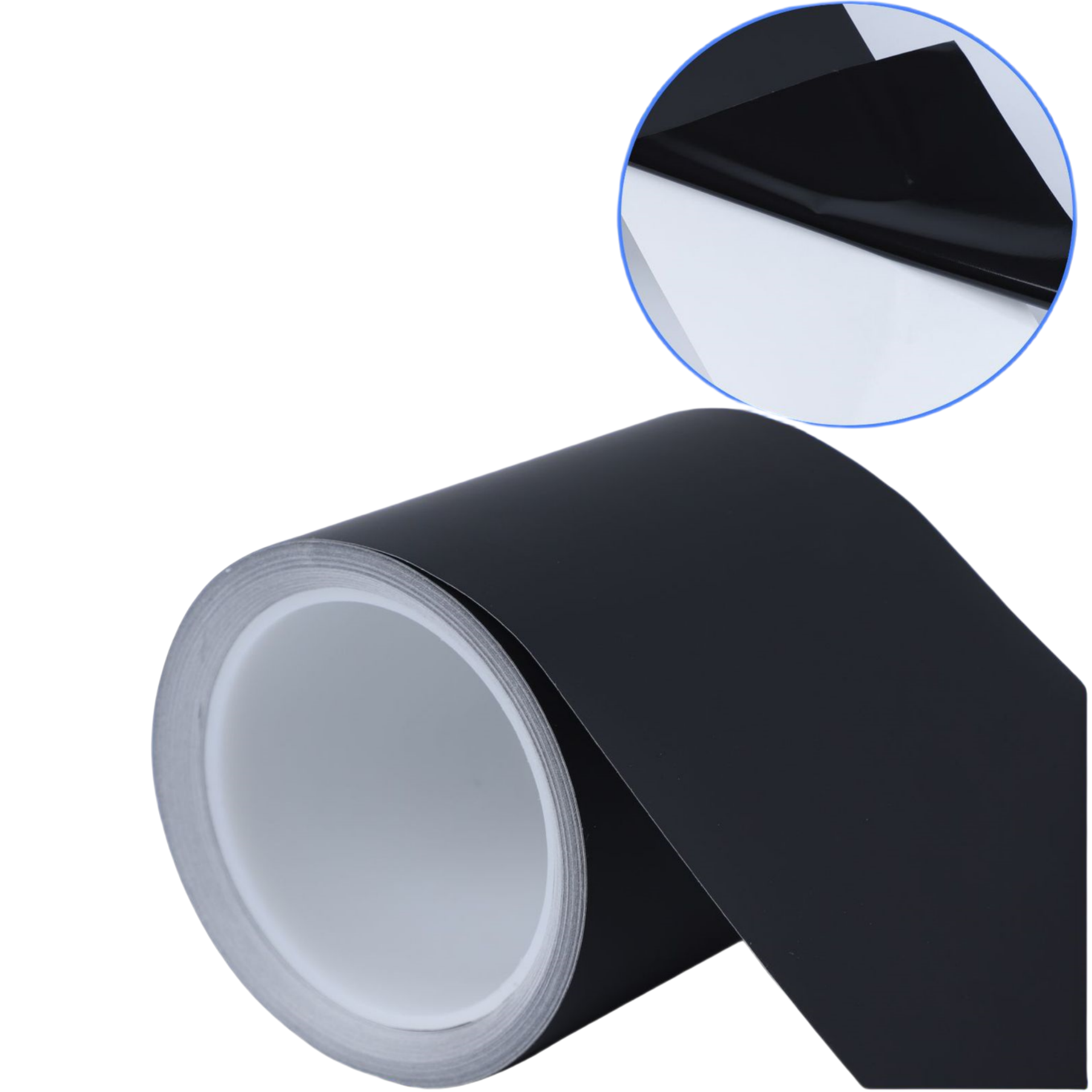

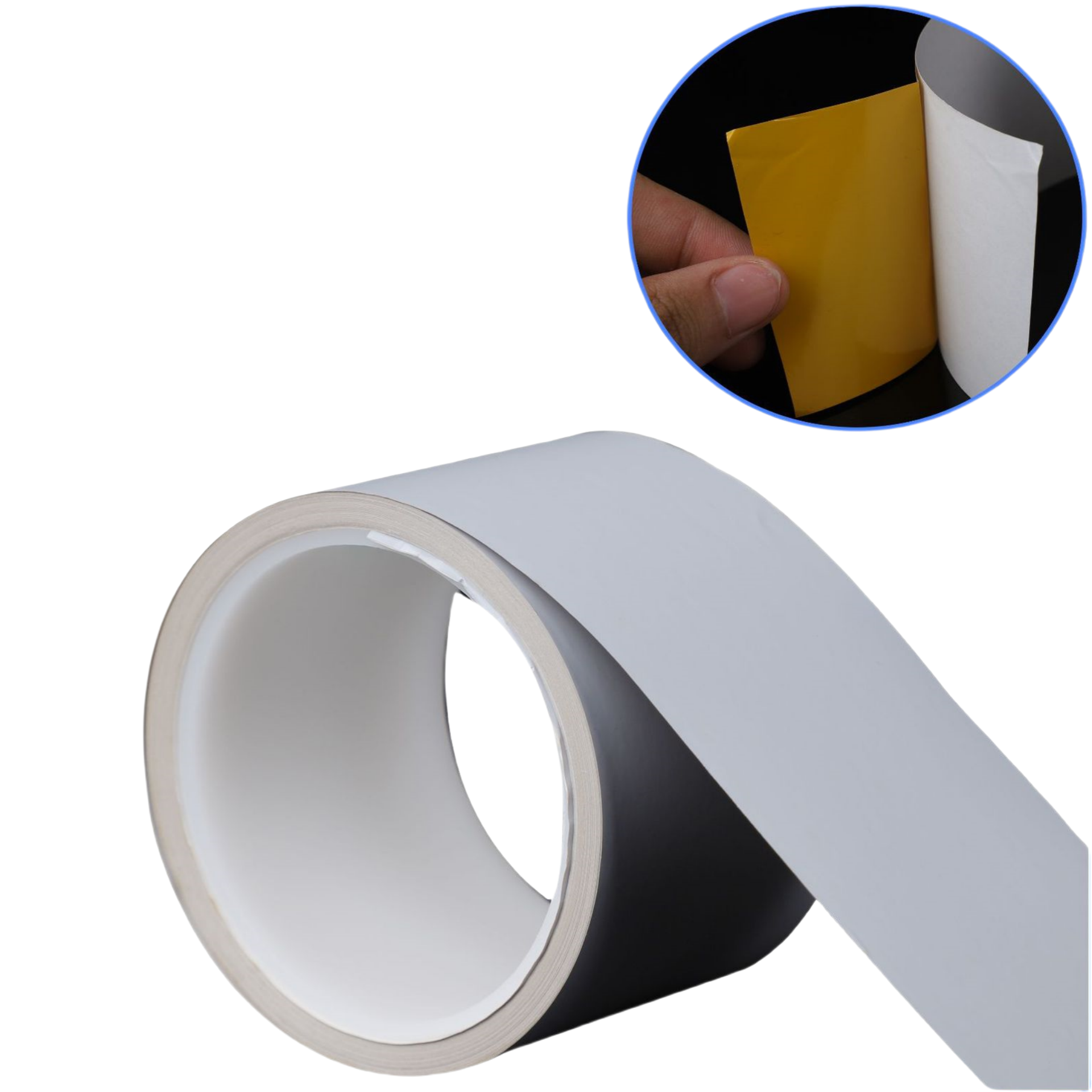

| Gloss white high temperature sticker material | Matte white high temperature label material | Matte black high temperature sticker label material |

|

|

|

| Grey high temperature sticker label material | Pink high temperature sticker label material | Yellow high temperature sticker label material |

|

|

|

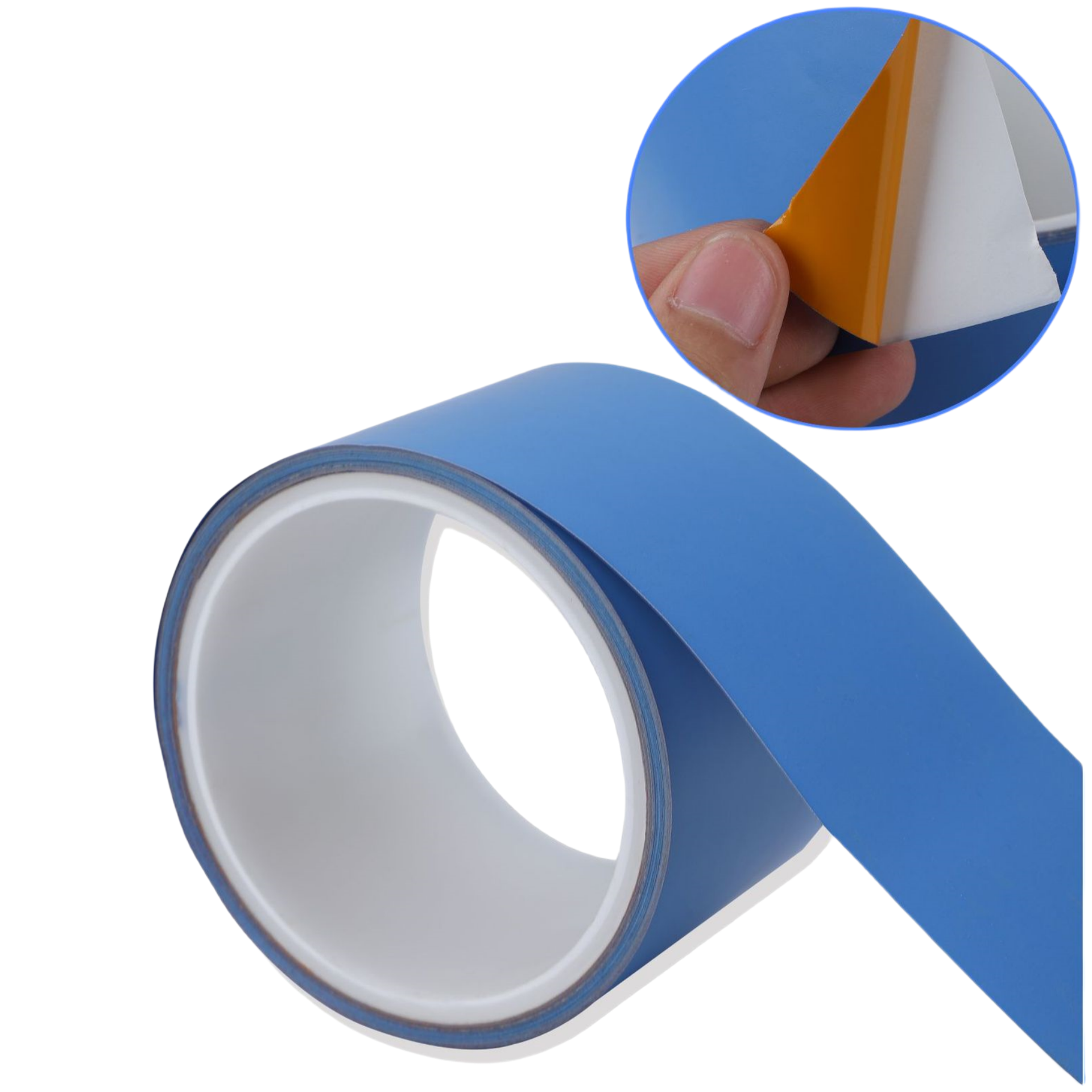

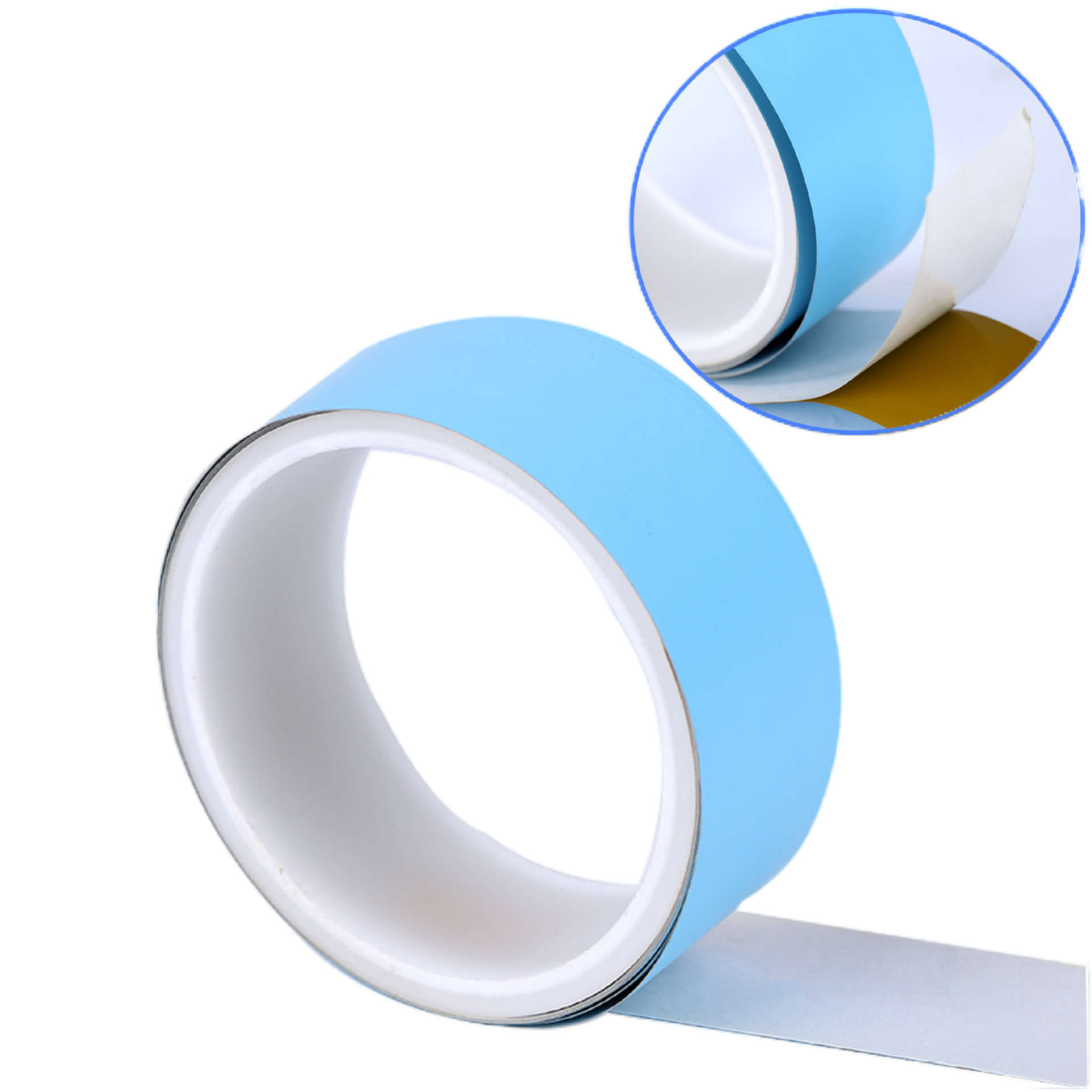

| Blue high temperature sticker label material | Green high temperature sticker label material | Grey high temperature sticker label material |

|

|

|

| Flame retardant high temperature label | Anti-static high temperature label | Transferable high temperature label |

Core characteristics

The base material of o adopts white polyimide (PI) film, which can withstand extreme temperatures ranging from -269°C to +260°C for a long time, with an instantaneous temperature resistance of up to 400° C. It is suitable for high-temperature welding, reflow soldering processes or harsh environments such as engine compartments.

It features an ultra-low thermal shrinkage rate, excellent dimensional stability in high-temperature environments, and prevents label warping or detachment.

It can resist the erosion of strong acids, strong alkalis, organic solvents (such as acetone, alcohol), oils and various industrial cleaning agents, ensuring the integrity of the label in complex chemical environments.

The O-polyimide substrate has excellent tear resistance and wear resistance, can withstand mechanical vibration, friction and repeated bending, and is suitable for marking curved surfaces or dynamic parts.

The white matte/glossy surface coating optimizes ink adhesion. Combined with heat transfer printing (resin-based carbon ribbons are recommended), high-precision patterns such as text, barcodes, and QR codes are firmly attached, resistant to scratches and wear, ensuring long-term clarity and legibility.

The o material has passed UL certification, with a high insulation grade (dielectric strength ≥5 kV/mm), and its flame retardancy complies with UL94 V-0 standard, ensuring the safety of electronic component identification.

It complies with RoHS, REACH and Halogen-Free requirements, and meets the demands of green manufacturing and global supply chain compliance.

Resistant to strong acids, strong alkalis, solvents and oils, it is suitable for industrial scenarios in contact with chemical reagents.

High tensile strength and flexibility, tear resistance, warping resistance, and no pressure when adhering to curved or irregular surfaces.

Typical application scenarios

Technical parameters

Optional specifications and services

Packaging and Storage

Quality Assurance

It has passed the ISO 9001 quality management system certification and provides batch traceability and third-party test reports (such as SGS).

If you have any questions about our head Stickers material products, please feel free to contact us.

Customer Feedback(1)

The Matte Black High Temperature Sticker Label Material is excellent! It holds up really well even in high heat, and the matte finish gives it a sleek, professional look. Definitely a product worth considering!