Stickers Key Attributes

Goods Name

Transferable Polyimide High Temperature Labels

Surface Substrate

Gram Weight

ISO536 67±3 g/m2

Surface Treatment

20 um Nano Transfer Coating

Stickers Adhesive

Dry Coating Weight(g/m²)

ISO536 50±5 gsm

Release Paper

Material Name

Press Finish White Glasin

Gram Weight

ISO536 80±3 g/m2

Physical Test Data

180°Release Force

FTM3 ≤150 g/25mm

180°Peeling Force On Steel Plate

FTM1 ≥5 N/25mm

20 min 90° Peel Viscosity

FTM 2 6 N/25mm

24 hours 90° Peel viscosity

FTM 2 8 N/25m

Application Temperature

-40 ~+ 300℃

Minimum sticking Temperature

10℃

Maximum Sticking Temperature

+40℃

Release Force(g/in)

FTM3 20-30g

Initial Tack

ASTM D3759 ≥3# ,Steel Ball#

Holding Power

FTM8 >24h Hour

Shelf Life

It can be stored for one year at a temperature of 23±2℃ and relative humidity of 50±5%

Package Size

Dimensions Standard Width

Valid Width:1070mm,Slitting Minimum Width:25mm

Dimensions Standard Length

500M 1000M

Core Size

Diameter 75mm* Width 1070mm

About Stickers Goods Packing

Logistics

Use wrapping film, corrugated paper to wrap the product, and then use packing rope to secure the card.

Express

Use wrap film and foam wrap, then use corrugated paper to wrap the edge products.

Storage

Keep indoor,airiness,avoiding high humidity and direct sunlight,can keep one year in room temperature & humidity.

Other Attributes

Initial Viscosity (st,st):

FTM 9 8 N/25mm

Short-time High temperature Resistance

At 300 ºC (572 ºF) for 90 seconds

Product Details

Product Overview

Transferable high temperature label is a special label material designed specifically for extreme high temperature environments, and is combined with a high-performance polyimidebase substrate and removable type resistant adhesive. The product is both excellent temperature resistance, chemical stability and removable properties, suitable for industrial scenarios that require long-term tolerance for high temperatures, frequent replacement labels or temporary identification. It is an ideal choice for electronic manufacturing, automotive industry and aerospace.

|

|

|

| Gloss white high temperature sticker material |

Matte white high temperature label material |

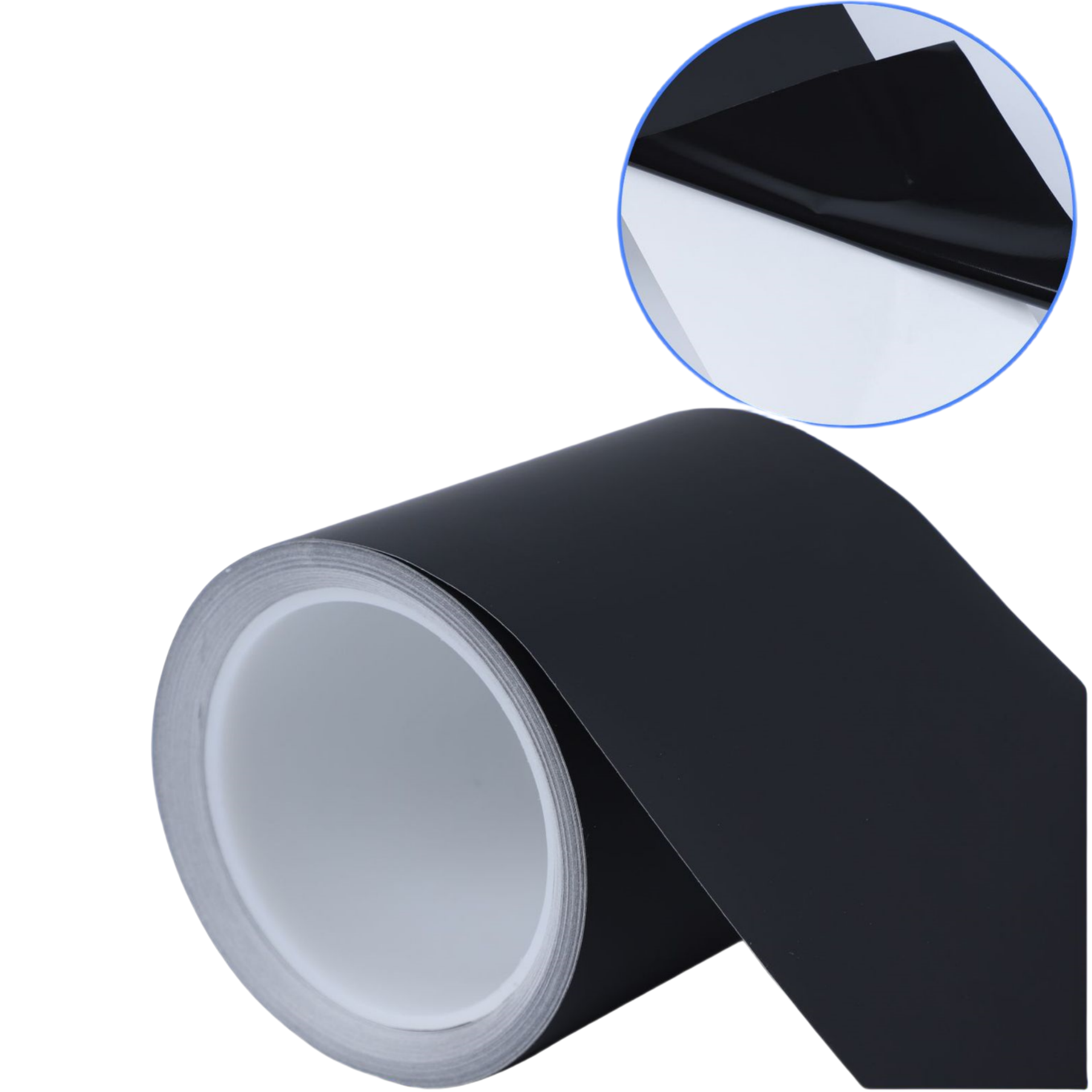

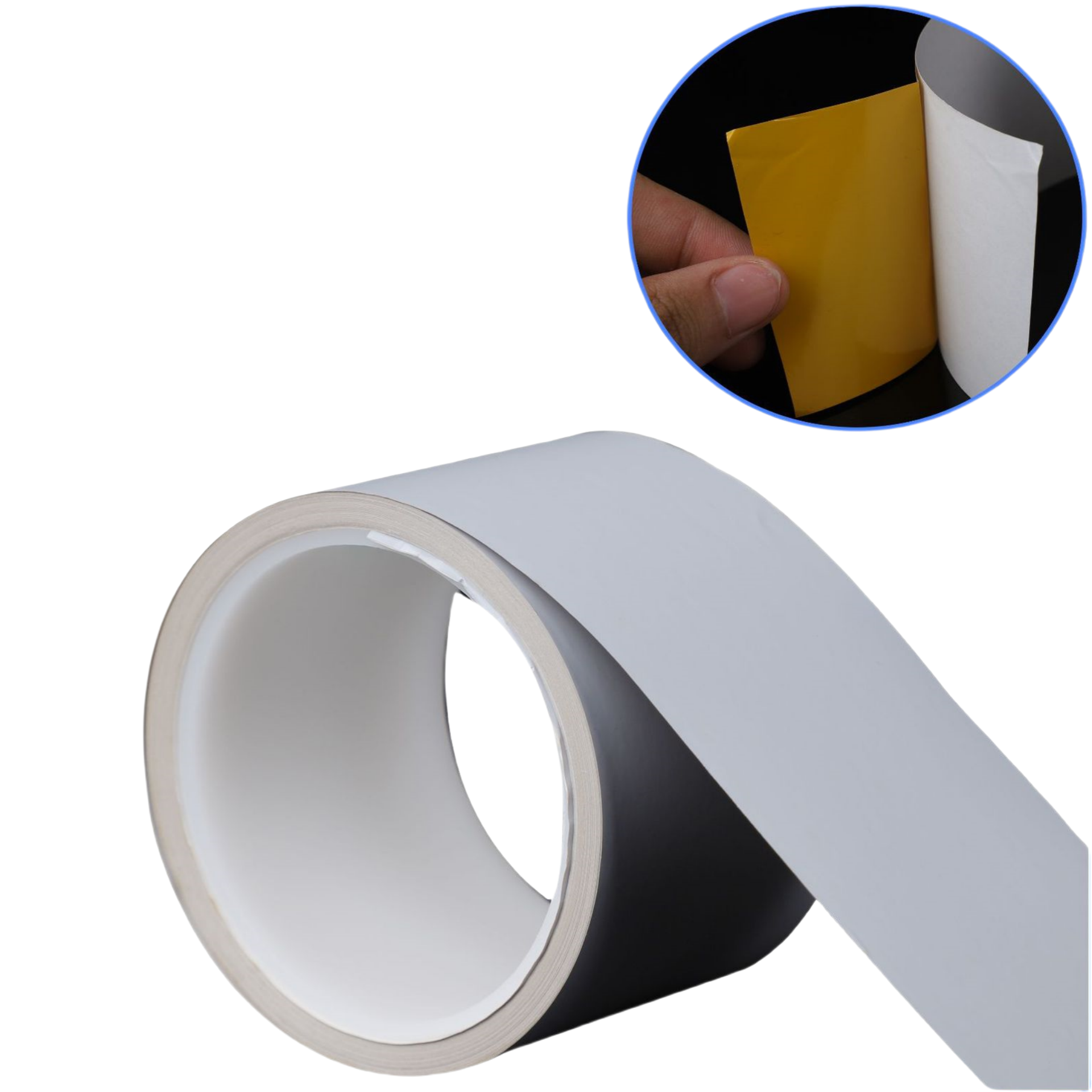

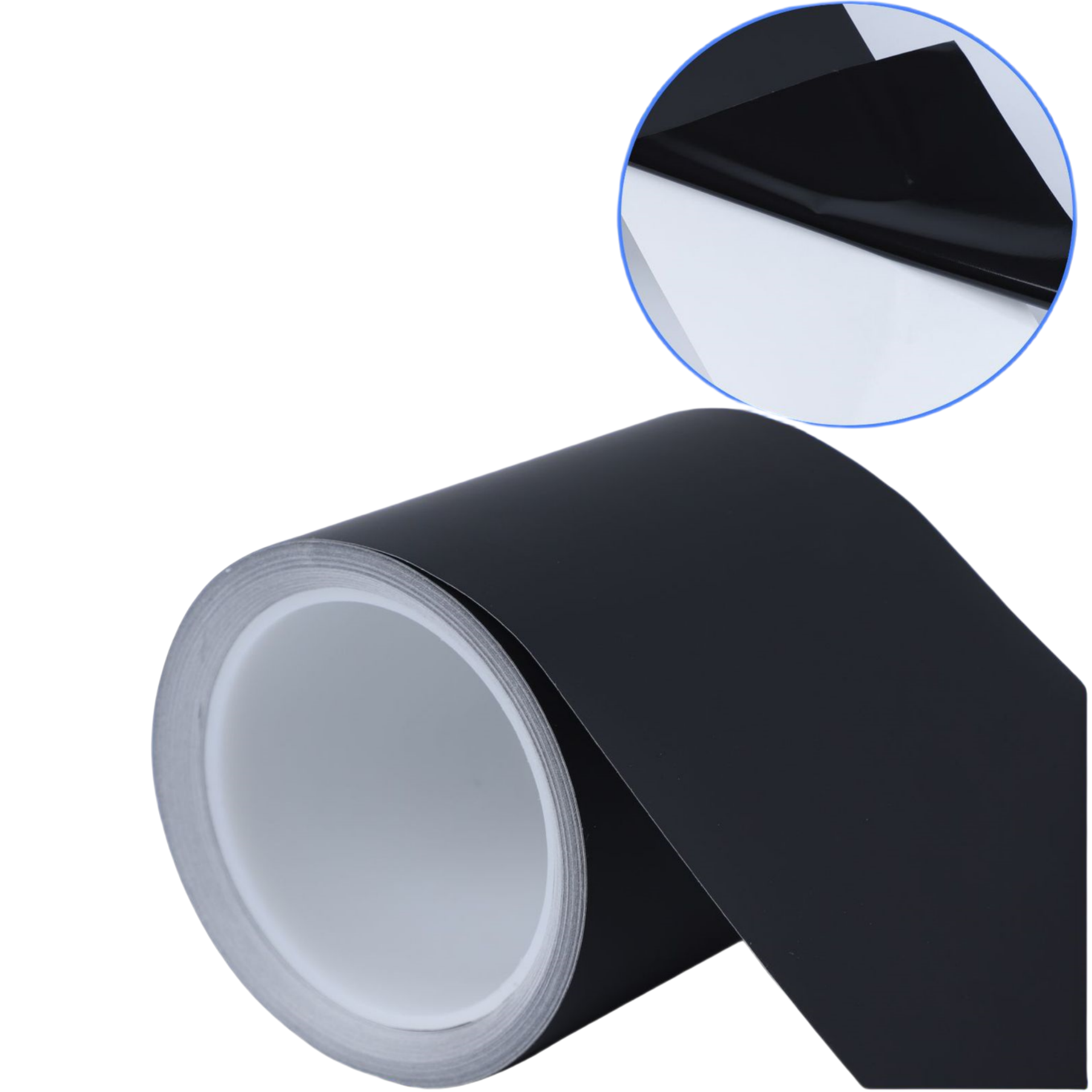

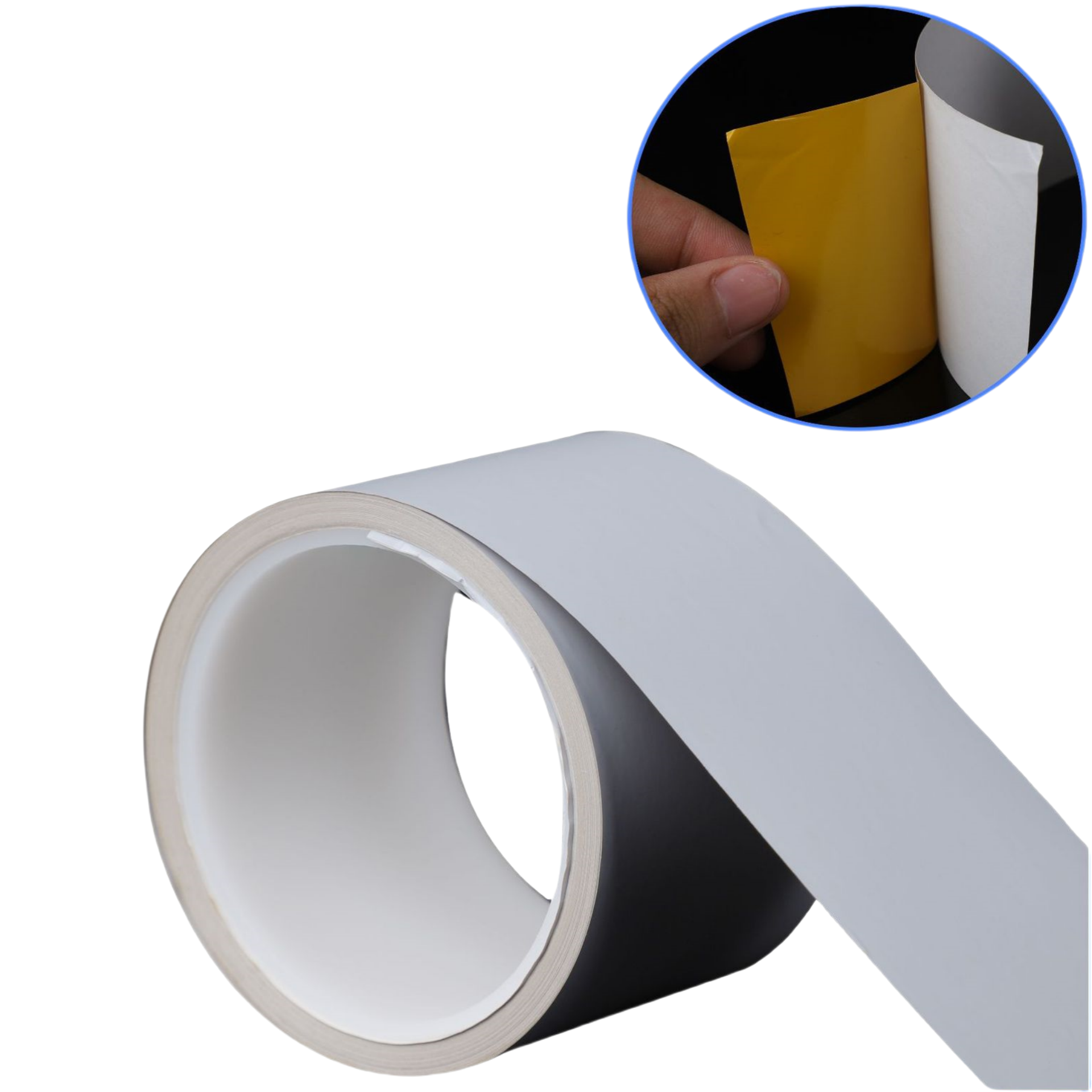

Matte black high temperature label material |

|

|

|

| Grey high temperature sticker label material |

Pink high temperature sticker label material |

Yellow high temperature sticker label material |

|

|

|

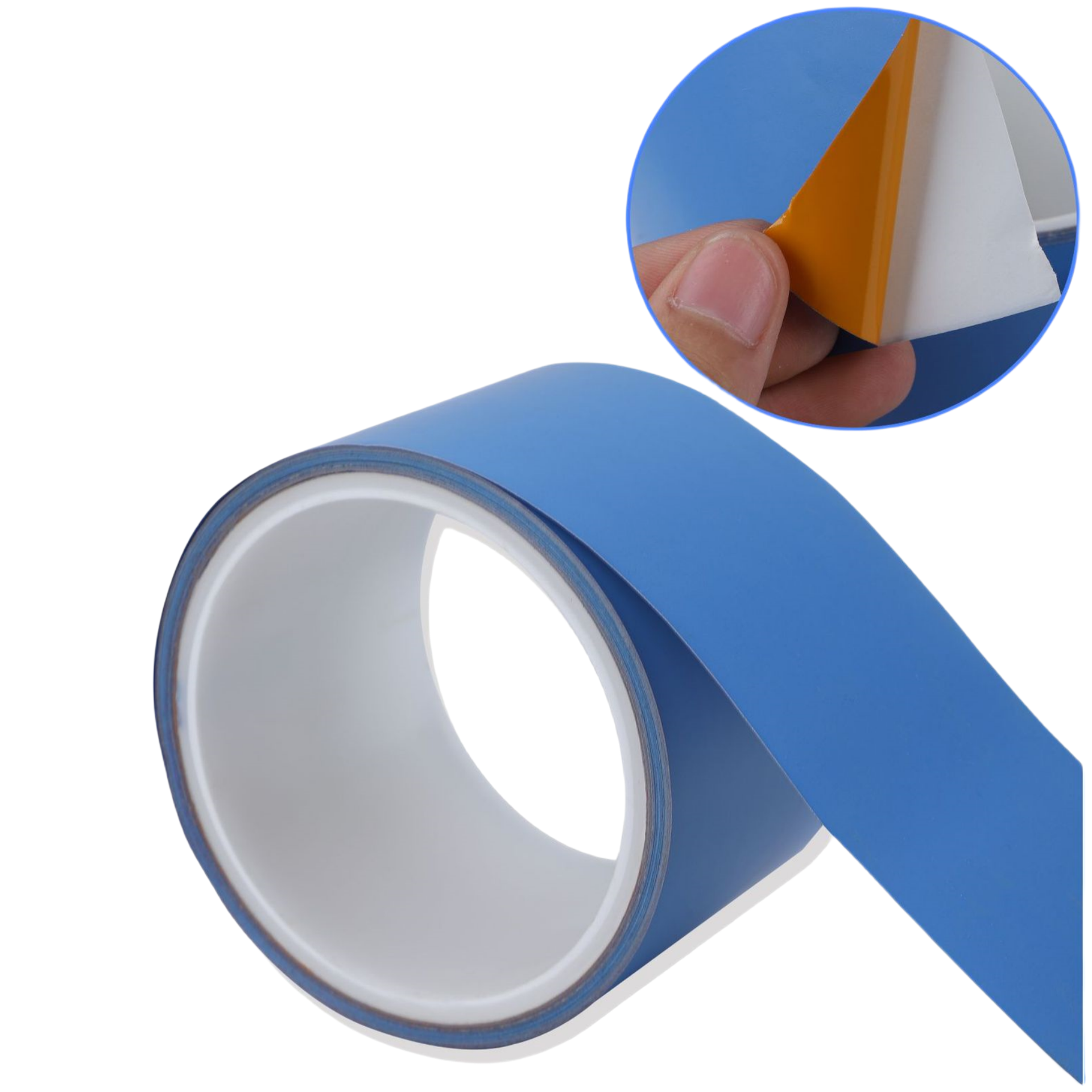

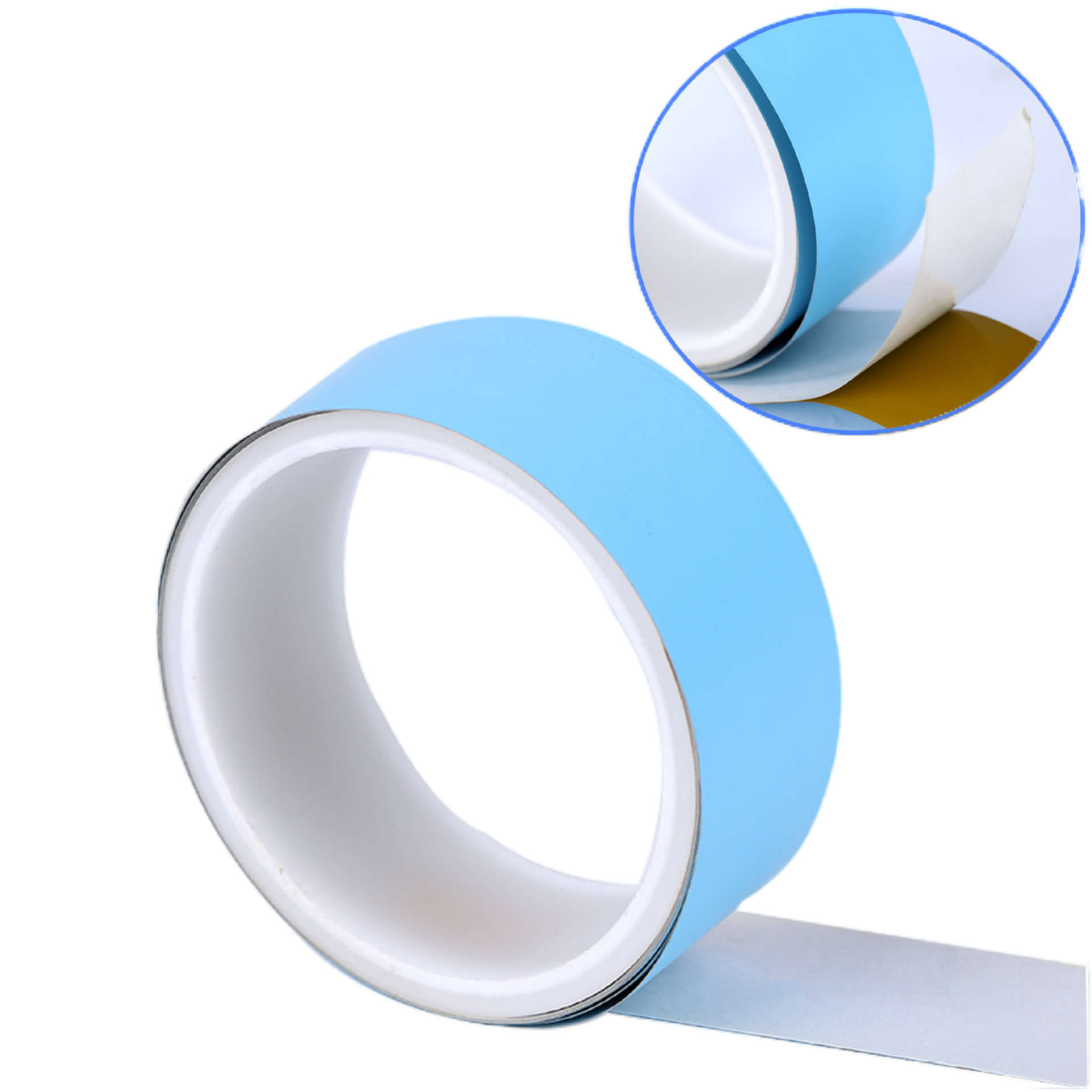

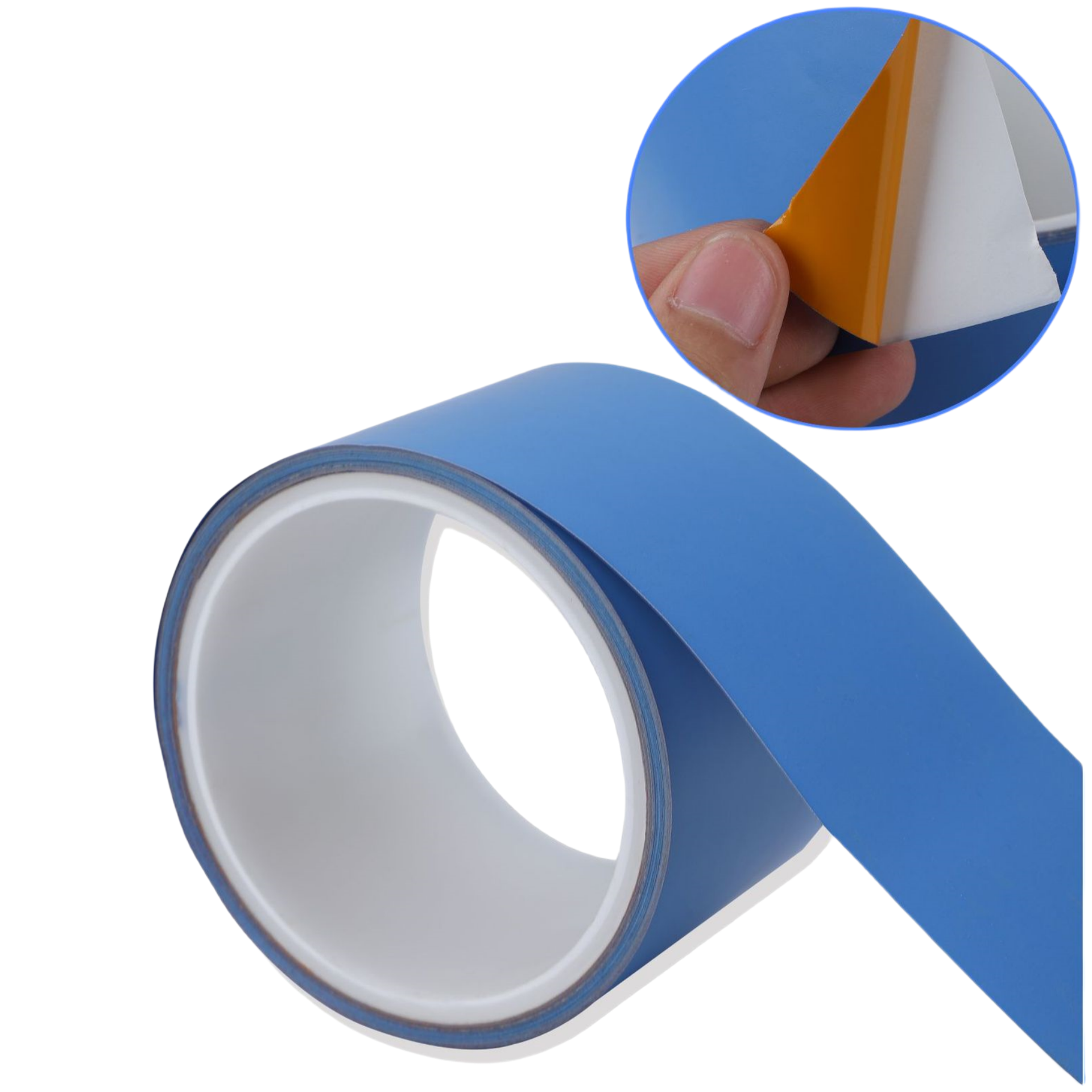

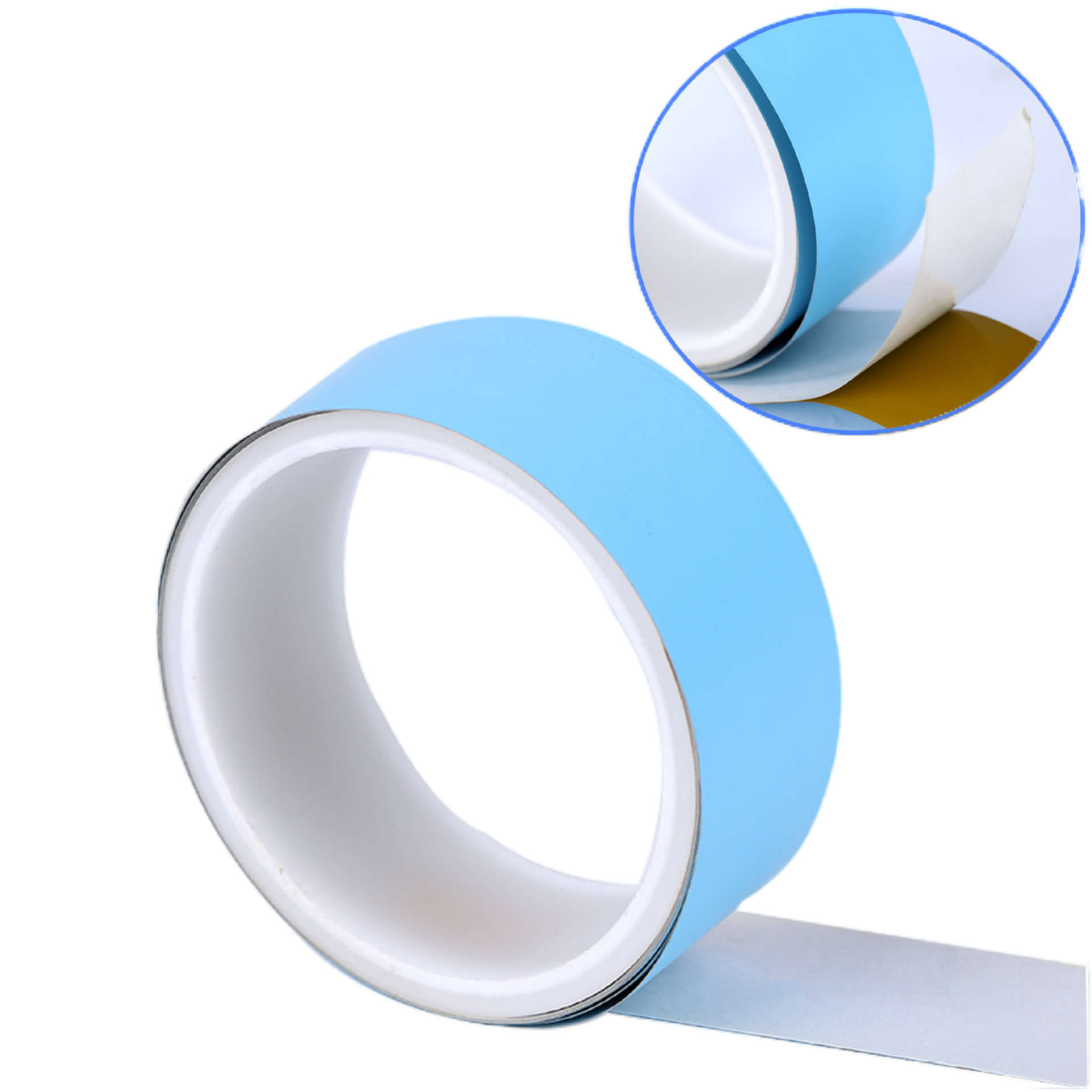

| Blue high temperature sticker label material |

Green Polyimide high temperature label material |

Grey high temperature label sticker material |

|

|

|

| Flame retardant Polyimide high temperature label |

Polyimide Anti-static high temperature label |

Polyimide Transferable high temperature label |

Core Advantage

- Outstanding high-temperature resistance

Long-term temperature tolerance range: -269°C to +260°C (up to 300°C for short periods), suitable for high-temperature processes such as reflow soldering and wave soldering.

There is no warping or cracking, ensuring that the label remains intact and readable during the thermal cycle.

- Chemical corrosion resistance and mechanical durability

It is resistant to strong acids, strong alkalis, organic solvents (such as alcohol, acetone), oils and salt spray corrosion, and is suitable for harsh environments such as chemical plants and automotive engine compartments.

The high-tear-resistant and wear-resistant surface design ensures the integrity and readability of the label even after long-term exposure.

- High-precision printing compatibility

Optimized for thermal transfer printing, when paired with resin-based carbon ribbons (recommended), it can present sharp text, barcodes and patterns, and is scratch-resistant without fading.

The grey matte surface offers high contrast, ensuring that scanning devices can identify quickly and accurately.

High-performance silicone or acrylic adhesives are available for selection, suitable for different material surfaces (metal, plastic, ceramic, etc.).

- Removable adhesive technology

It adopts a special silicone or acrylic removable adhesive system. After pasting, it is firm without lifting edges. When removed, there is no residual glue and the surface is not damaged.

Supports repeated pasting (3-5 times), suitable for scenarios such as temporary identification, device debugging, or frequent updates.

- Environmental protection and safety

Compliant with RoHS and REACH regulations, halogen-free, and meeting the environmental protection requirements of the electronics industry.

Typical application scenarios

- Electronics industry: High-temperature process tracking labels for PCB boards, flexible circuit boards (FPC), electronic components, and power modules.

- Automobile manufacturing: Engine compartment wiring harness marking, oil-resistant sensor labels, permanent marking for on-board electronic devices.

- Aerospace: Component tracking labels and equipment maintenance record identifiers resistant to extreme temperatures and radiation.

- Medical equipment: Labels for devices that can withstand autoclaving and chemical disinfection, meeting medical-grade durability standards.

- Industrial manufacturing: Nameplates for high-temperature equipment, labels for chemical containers, traceability for automated production lines.

Technical parameters

- Attribute specification value

- Substrate thickness: 25μm / 50μm / 75μm (optional)

- Surface treatment: matte/glossy coating

- Adhesive type: High-temperature resistant silicone pressure-sensitive adhesive

- Peel strength (for stainless steel) ≥8 N/25mm

- Shelf life: 24 months (Store in the original packaging away from light)

Usage Suggestions

- Printing parameters: The recommended printing temperature is 120 - 140℃, and the speed is 50 - 80mm/s (the specific parameters need to be adjusted according to the printer model).

- Labeling requirements: Clean the surface of the object to be labeled to ensure there is no oil, dust; Apply uniform pressure after labeling to enhance adhesion.

- Customized service: Supports roll material cutting, die-cutting of special-shaped labels, pre-printing of serial numbers/QR codes, etc. to meet personalized requirements.

Why choose our polyimide labels?

- Full scene compatibility: From extremely low temperatures to extremely high temperatures, from laboratories to outdoor extreme environments, the identification integrity can be maintained.

- Data reliability: Specifically designed for the Industrial 4.0 traceability system, it ensures the readability of data for over ten years and reduces maintenance costs.

- Quick Response: Offer technical consultation, sample testing and customized solutions to help customers efficiently address complex identification challenges.

Optional specifications and services

- Customized services: Support processing requirements such as pre-die-cutting of labels, slitting of rolls, and back printing of serial numbers.

- Recommended compatible carbon ribbons: Resin-based carbon ribbons (such as Wax-Resin or all-resin carbon ribbons) to ensure the best printing durability.

Packaging and Storage

- Standard packaging: Roll material (maximum outer diameter 300mm, core diameter 76mm), wrapped with anti-static film.

- Storage conditions: It is recommended to store in a cool and dry place (temperature 15-30°C, humidity 40-60%).

Quality Assurance

It has passed the ISO 9001 quality management system certification and provides batch traceability and third-party test reports (such as SGS).

Product FAQ

The polyimide film offers superior thermal stability and mechanical strength, keeping labels intact through multiple high-temperature cycles.

Yes, it is widely used in SMT and PCB manufacturing, where components must endure soldering processes reaching up to 300℃.

Yes, the surface is compatible with thermal transfer printing. When paired with resin ribbons, it produces durable and heat-resistant prints.

The white polyimide coating resists yellowing and maintains excellent print clarity even at temperatures up to 300℃.

No, the high-temperature acrylic adhesive remains stable within -40℃ to +300℃, ensuring strong and lasting adhesion.

It is designed to perform reliably from -40℃ to +300℃, making it suitable for both extreme cold and high-heat environments.

If you have any questions about our head Stickers material products, please feel free to contact us.

Customer Feedback(1)

The Transferable Polyimide High Temperature Labels did a great job. They transferred smoothly and held up well under heat, looking clean and intact throughout