Because the fiber tissue is relatively uniform, the surface layer has the composition of filler and rubber, and the surface is coated with a certain paint, and after multi-roll calendering treatment, the texture of the cardboard is relatively tight, and the thickness is relatively uniform.

Product Review:Because the fiber tissue is relatively uniform, the surface layer has the composition of filler and rubber, and the surface is coated with a certain paint, and after multi-roll calendering treatment, the texture of the cardboard is relatively tight, and the thickness is relatively uniform. Under normal circumstances, the paper is relatively white and smooth, with more uniform ink absorption, surface depowder and hair loss phenomenon is less, the paper is stronger and has good folding resistance, but its water content is high, generally about 10%, there is a certain flexibility, which will bring a certain impact on printing. The difference between whiteboard paper and coated paper, offset paper, letterpress paper is that the paper gram weight, the paper is relatively thick and the front and back colors are different, the whiteboard paper is a gray side white, also known as gray bottom coated white.

The Composition Of Whiteboard Paper:

The white board paper is made from the dough and each layer of bottom pulp in a multi-cylinder paper machine or a long cylinder mixing board machine. The pulp is generally divided into pulp (surface layer), two layers, three layers, four layers, the fiber ratio of each layer of pulp is different, and the fiber ratio of each layer of pulp is different according to the quality of the paper.

The first layer is the surface pulp, which requires high whiteness and has a certain strength, usually using bleached sulfate wood pulp or adding part of bleached chemical straw pulp and white paper edge waste pulp;

The second layer is the lining layer, which plays the role of isolating the surface layer and the core layer, and also requires a certain whiteness, usually with 100% mechanical wood pulp or light-colored waste pulp;

The third layer is the core layer, which mainly plays the filling role to increase the thickness of the cardboard and improve the stiffness. Generally, mixed waste pulp or straw pulp is used. This layer is the thickest and the cardboard with high quantitative quantity is commonly used to hang the pulp several times. The last layer is the bottom layer, which has the function of improving the appearance of the cardboard, improving the strength and preventing curling, usually made with high yield pulp or better waste pulp as raw materials, the bottom color of the cardboard is more than gray, and other bottom colors can also be produced as required.

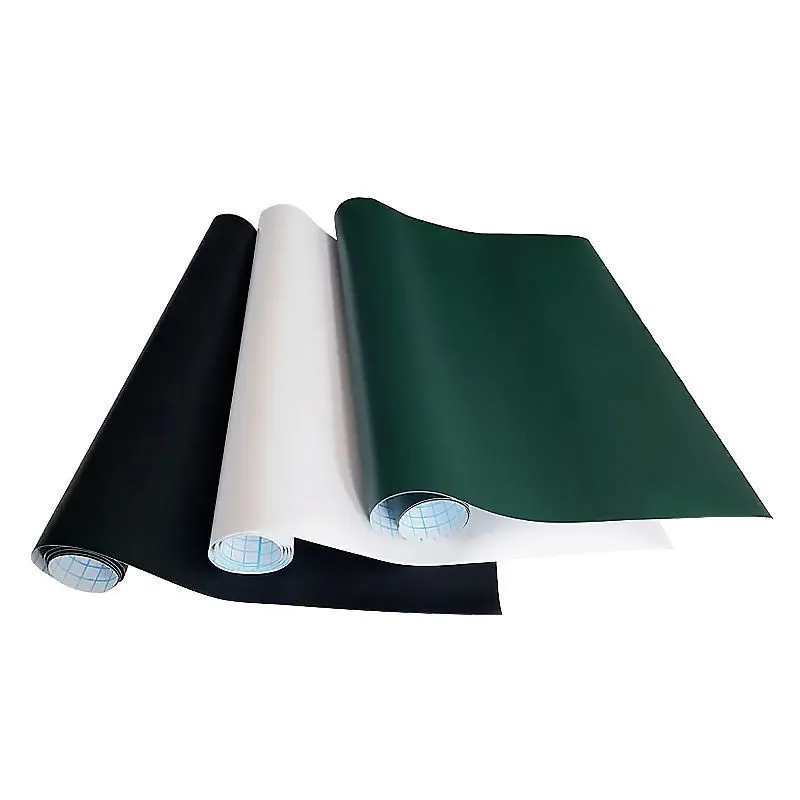

Erasable Whiteboard Sticker Type:

Specification Parameter:

1. By gram weight:

The conventional gram weight of whiteboard paper is: 230 g/m2, 250 g/m2, 270 g/m2, 300 g/m2, 350 g/m2, 400 g/m2, 450 g/m2, 500 g/m2, etc.

2. In terms of format:

Common plate specifications of whiteboard paper: positive 787mm*1092mm, generous 889mm*1194mm.

Whiteboard paper commonly used drum specifications: 26 "/ 28"/" / 33 "31/35" / 36 "/ 38" / 40 "43" / 47 ".

Other sizes of whiteboard paper are available to order.

Advantage:

During the discussion, record the speaker's views at any time to avoid confusion and forgetting (adults' short-term memory limit: only 5-9 ideas can be remembered at most).

You can use stick figure techniques to draw graphics, so that the audience can quickly understand.

After the meeting, it is easy to organize: if the assigned number of people organize the research data on the day, they can be taken away separately.

In the second meeting, you can post the core ideas of the previous meeting again to evoke memories.

In the event of a sudden power failure in the meeting room, the course can continue without the need for a computer or computer projector.

When purchasing whiteboard markers, we should distinguish from the following aspects:

1、 Distinguish by the smell of whiteboard ink

Most of the whiteboard ink on the market now is alcohol-soluble ink; Its main solvent medium is fatty alcohol, generally alcohol as the main solvent, with other additives, and now the technology is increasingly mature, and has been widely used, is currently the main varieties of white board ink. Good whiteboard ink open cap after only light alcohol smell slowly floating out, and no other bad smell. If there are other pungent and unpleasant smells, it means that the ink may contain odor masking agent, banana water and other harmful ingredients.

2、Indirect writing effect

Indirect writing is also called hat off moisture, some foreign data is also called anti-drying time or anti-drying time, generally in accordance with European standards: temperature 22 ° C ~ 25 ° C, humidity 50% under the conditions, do not wear a pen cap, placed for a certain period of time, can still write normally. The whiteboard ink on the market is only 3-4 hours, and the good whiteboard ink has 8 hours, 12 hours or 24 hours according to the origin, and even 72 hours, but then, the trend has an impact on other properties.

3、 Erasability

Erasability is generally divided into instant erasable and delay erasable two kinds, instant erasable is written on the white board after 30 seconds with a board eraser or soft cloth is easy to erase, and does not paste the board or leave "ghost"; Delay erasable means that the handwriting written on the whiteboard can still be erased after a period of time, generally according to the user's requirements of several days, ten days, dozens of days. The length of the board time also reflects the actual level of the whiteboard ink, generally with a long board time is better.

Applicable Occasion:

A variety of formal and informal seminar/learning occasions. facilitation, training, coaching, coaching process, workshop, cross-departmental and intra-departmental discussion, etc.

Since guidance technology is widely used in enterprise strategy formulation, process reengineering, R&D innovation, brainstorming, business plan formulation, overall budget formulation, marketing strategy formulation, etc., whiteboard paper will also be suitable for formal and informal discussion/learning occasions such as enterprises, government agencies, non-governmental organizations (ngos).

If you have any questions about our head Stickers material products, please feel free to contact us.

Customer Feedback(1)

I tried the Erasable Whiteboard Sticker Material on a wall in my workspace, and it’s super handy. It sticks well, writes smoothly with dry-erase markers, and wipes clean without leaving stains. Great for quick notes and planning without taking up desk space