Tear Proof Rubbing Paper Material is a durable labeling solution that resists tearing and friction, ensuring long-lasting p

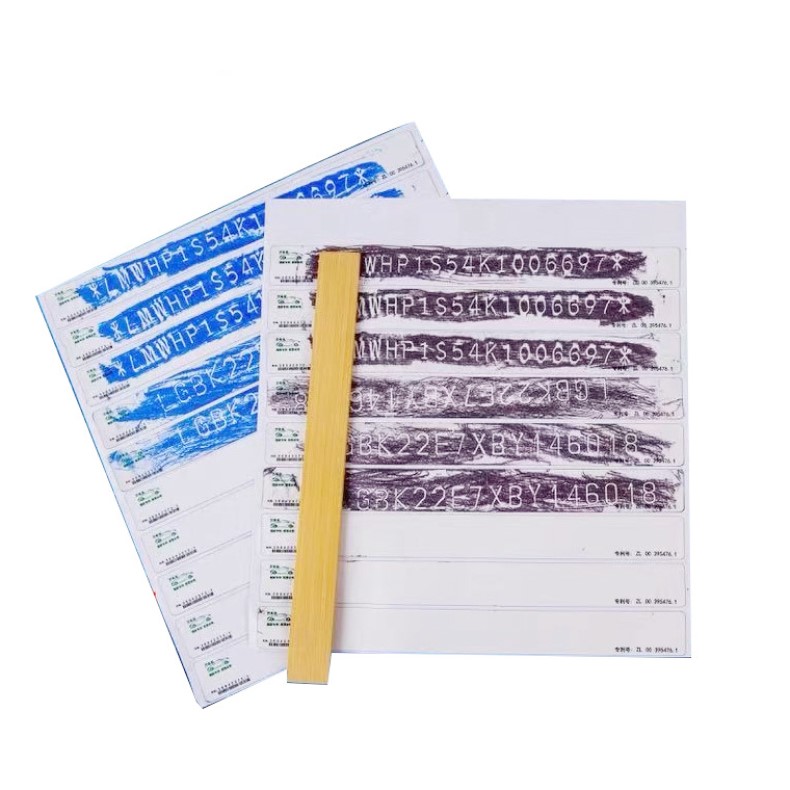

Product Review:Traditional rubbing papers often tear during separation, causing repeated work and wasted time. The OwnLikes Tear Proof Rubbing Paper Material integrates a carbon-free self-developing paper layer with PET film, coated with strong adhesive and protective backing. This structure makes the Tear Proof Rubbing Paper Material durable, convenient, and reliable.

The tear resistant rubbing paper material is ideal for fast expansion of codes in motor vehicles, freezers, and heavy equipment. Its clear handwriting, complete rubbing, and long-term storage ability make the Tear Proof Rubbing Paper Material highly practical.

OwnLikes has developed a Tear Proof Double Layer Rubbing Paper, solving previous shortcomings. It allows two rubbings with the same graphics in one construction, featuring waterproof, anti-oil, and anti-tear properties.

The design of the Tear Proof Rubbing Paper Sheet is die-cut and hand-torn for quick separation. This improves efficiency compared to single-layer paper that required two operations. As a result, the Tear Proof Rubbing Paper Material shortens working time, saves resources, and increases output.

Motorcycle: 80×20mm, 80×30mm, 100×20mm, 120×20mm

Car: 100×30mm, 120×25mm, 120×30mm, 150×25mm, 160×20mm, 160×25mm, 170×20mm, 180×20mm

Passenger Car/Truck: 120×40mm, 180×22mm, 180×25mm, 200×20mm, 200×22mm

Custom sizes available.

Rubbing Color: black, blue (indicate request).

Remove the sticker from the bag.

Peel off the bottom layer.

Place flat on the surface and smooth gently.

This rubbing paper sticker material relies on static adhesion, eco-friendly and reusable. Many appliance manufacturers replace traditional self-adhesive labels with Tear Proof Rubbing Paper Material for better results.

Recommended storage: 22±2°C, 50%±5% RH.

Seal packaging with plastic film after each use.

Store on wooden boards, avoid overload.

Prevent direct sunlight and glue penetration.

Maintain consistent environment to protect the Tear Proof Rubbing Paper Material.

When properly stored, the Tear Proof Rubbing Paper Material keeps adhesive for 3 years and rubbing colors for 100 years. Vehicle manufacturers should control storage conditions (18–30°C, 40–60% RH).

The Tear Proof Rubbing Paper Material contains flammable components. Avoid stacking too tightly, maintain safety channels, and prevent fire risks.

The OwnLikes Tear Proof Rubbing Paper Material provides superior durability, high clarity, and long-lasting performance. With waterproof, anti-oil, and anti-tear properties, this tear proof double layer rubbing paper is the perfect choice for efficient code expansion, long-term archiving, and professional applications.

Choose OwnLikes Tear Proof Rubbing Paper Material today for reliability and productivity.

If you have any questions about our head Stickers material products, please feel free to contact us.

Customer Feedback(1)

Tried the Tear Proof Rubbing Paper Material and it really holds up! It’s tough, resistant to tearing even under pressure, and perfect for items that get handled a lot. Definitely reliable for both functional and creative use.