Red anti-counterfeiting label characteristics when encountering water

1.The main function of turning red when in contact with water is that when the substrate is completely exposed to water, the surface will turn red when in contact with water, and the color will be significantly different from before, and irreversible.

2. It turns red when exposed to water. Based on the critical humidity at which the product is damaged after exposure to water, it can be designed to change color according to the preset relative humidity or only when completely immersed in water.

3. There are two main types of waterproof labels that turn red when exposed to water. One type is water diffusion: when the water turns red label is immersed in water, the original pattern on the label will quickly spread around it. Another way to turn red when in contact with water is to show color when in contact with water: when the water turns red label is immersed in water, the original water turns red label color will quickly spread and completely change to another preset color.

4. It can be used to produce anti-counterfeiting labels for electronic products such as mobile phones, lithium batteries, MP3 players, etc. that turn red when exposed to water. There are various sizes and shapes of water turning red labels, water changing color labels, anti-counterfeiting labels, and waterproof labels.

5. White writing paper substrate, with a permanent acrylic pressure-sensitive adhesive surface coating formula that turns red after immersion, suitable for heat transfer printing and handwriting.

6. Provide design assistance for maintenance services, control non compliant warranties, and analyze errors.

Usage of anti-counterfeiting labels that turn red when exposed to water

Turning red when in contact with water is a warranty service for products such as mobile phones, batteries, electronics, appliances, LCDs, etc. that are difficult to identify or incorrectly identified after being damaged by water, and do not meet the conditions for control. At the same time, turning red when in contact with water is also a new type of product developed for identifying water ingress in long-distance transportation goods and providing legal basis for claims. The main function of the water turning red label is to show that when the substrate is completely exposed to water, the surface will turn red when exposed to water, and the color will be significantly different from before, and irreversible.

The anti-counterfeiting label that turns red when encountering water can accurately detect abnormal results when entering the liquid. When abnormalities occur, the responsible party can be clearly identified to protect the rights and interests of both merchants and consumers. Turning red when in contact with water has a strong sensitivity to humidity and can accurately display the degree of moisture on the surface. Turning red when in contact with water is mainly used to test the identification of product entry and can have an aesthetic effect. Clearly define the responsibility for circuit damage caused by liquid ingress in electronics, circuits, batteries, mobile phones, etc.

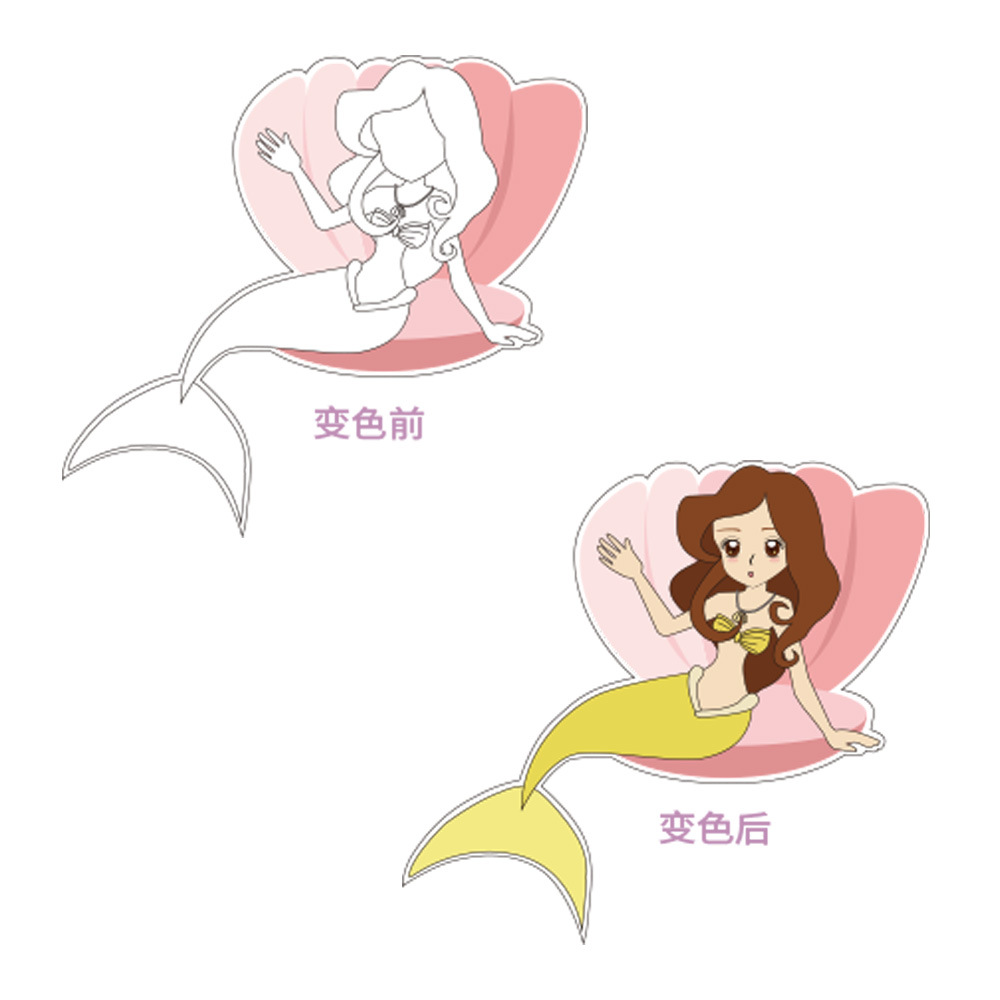

Water discoloration label (disappearing type)

The surface color of the water color changing (drip disappearing type) label is white, and it becomes transparent upon contact with water, revealing the base color; The pattern or text of the printed label will fade colorless when exposed to water, and will recover when the water dries. Directly printed on the surface of the product, the color becomes white after drying, and becomes transparent when exposed to water, revealing the base color. Has good adhesion and color changing effect, fast color changing speed, and good covering power. Reusable.

Characteristics of water discoloration label (disappearing type)

Water discoloration refers to the phenomenon where water-based silk screen printing ink appears white, becomes transparent upon contact with water, and returns to its original state after drying. Due to its transparency upon contact with water and absence of harmful materials, it has obtained EN71-3 testing and is a safe water-based silk screen color changing ink suitable for printing various types of adhesive stickers.

Substances that change color when in contact with water include:; Anhydrous copper sulfate, anhydrous cobalt chloride, sodium peroxide, etc.

Anhydrous copper sulfate: originally white, turns blue when in contact with water;

Anhydrous cobalt chloride: originally dark blue, turns pink when in contact with water;

Sodium peroxide: originally light yellow, turns white when in contact with water.

Copper sulfate (CuSO4) is a white or off white powder. Its aqueous solution is weakly acidic and appears blue. The common form of copper sulfate is crystalline, with copper sulfate monohydrate ([Cu (H2O) 4] SO4 · H2O, copper sulfate pentahydrate) as a blue solid (crystal). Its aqueous solution appears blue due to the presence of hydrated copper ions, so anhydrous copper sulfate is often used in the laboratory to test for the presence of water.

Is the water discoloration label toxic?

Water discolored labels are usually non-toxic. This type of label is made of special materials and developed through special processes, which can change color when exposed to water. These materials strictly comply with national laws and regulations on environmental protection and safety during the manufacturing process, and have passed multiple tests including heavy metal, toxicity, solvent residue, etc. The dried printing film is actually non-toxic, and the product formula does not contain any actual toxic ingredients. Therefore, the water color changing label is safe under normal use and will not pose a threat to human health. However, to ensure safety, it is recommended to follow the product instructions and precautions when using.

We offer comprehensive technical support, including free professional labeling solutions, advice on label materials and adhesive selection, as well as online/offline assistance from professional software and hardware engineers. Service email: andy@ownlikes.cn. In pre-sales, we leverage our extensive experience in specialty labeling projects to provide clients with the most suitable hardware solutions. Additionally, all our label barcode printers and scanners come with a three-year free warranty, demonstrating our confidence in our products.