Aluminum foil adhesive label

Aluminum foil adhesive labels, as a type of adhesive label made of aluminum foil material, have gradually gained attention in the market in recent years. This type of label, with its unique metallic texture, excellent moisture resistance, and good thermal stability, has demonstrated extensive application potential in many industries and fields.

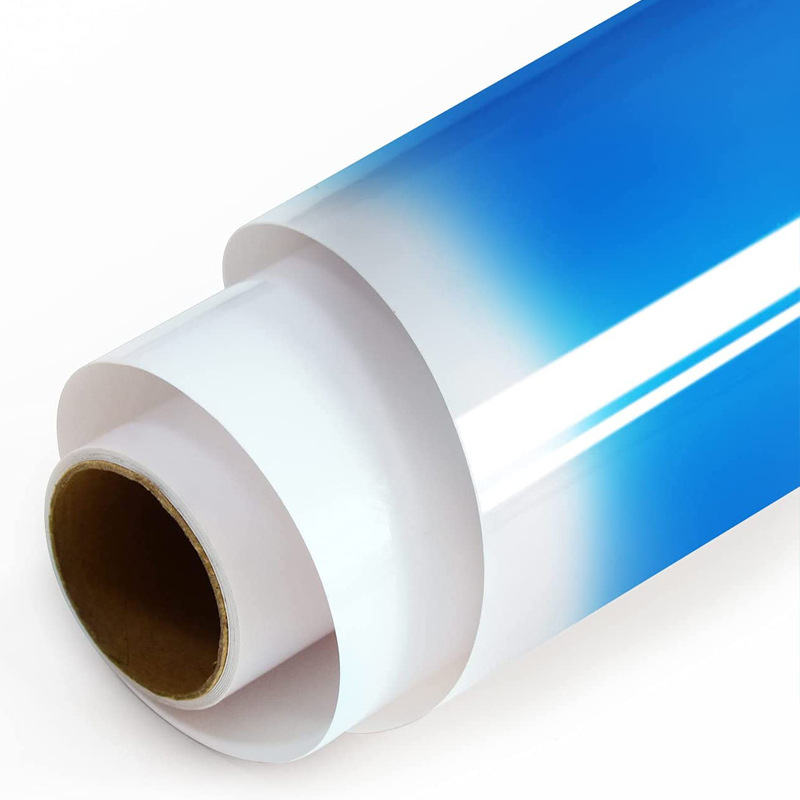

The main feature of aluminum foil adhesive labels is their aluminum foil material. Aluminum foil, as a lightweight and high-strength metal material, has excellent moisture resistance, oxidation resistance, and high temperature resistance. This allows aluminum foil adhesive labels to maintain clear patterns and text in humid, high-temperature, or long-term storage environments, and is not easily faded or deformed.

In addition to excellent physical properties, aluminum foil adhesive labels also have unique visual effects. The metallic texture of the surface makes the label more eye-catching and attractive, effectively enhancing the product's grade and added value. At the same time, aluminum foil material also has good printing adaptability, which can support various exquisite patterns and text printing, meeting the needs of personalized customization.

Aluminum foil adhesive labels are widely used in various industries and fields such as food, pharmaceuticals, cosmetics, and electronic products. In the food industry, it can be used for moisture-proof labeling on packaging; In the pharmaceutical industry, it can be used for anti-counterfeiting labeling on drug packaging; In the electronics industry, it can be used for labeling information such as serial numbers and barcodes on products. In short, aluminum foil adhesive labels have become a highly favored label product in the market due to their unique material, excellent performance, and wide range of applications.

Characteristics of Aluminum Foil Adhesive Labels

Aluminum foil adhesive labels, as a type of adhesive label made of aluminum foil material, have gradually gained attention in the market in recent years. This type of label, with its unique metallic texture, excellent moisture resistance, and good thermal stability, has demonstrated extensive application potential in many industries and fields.

The main feature of aluminum foil adhesive labels is their aluminum foil material. Aluminum foil, as a lightweight and high-strength metal material, has excellent moisture resistance, oxidation resistance, and high temperature resistance. This allows aluminum foil adhesive labels to maintain clear patterns and text in humid, high-temperature, or long-term storage environments, and is not easily faded or deformed.

In addition to excellent physical properties, aluminum foil adhesive labels also have unique visual effects. The metallic texture of the surface makes the label more eye-catching and attractive, effectively enhancing the product's grade and added value. At the same time, aluminum foil material also has good printing adaptability, which can support various exquisite patterns and text printing, meeting the needs of personalized customization.

It is worth mentioning that aluminum foil adhesive labels also have excellent environmental performance. Aluminum foil material can be recycled and reused, reducing the burden on the environment. In today's society that emphasizes sustainable development, this feature makes aluminum foil adhesive labels more popular.

Aluminum foil adhesive labels are widely used in various industries and fields such as food, pharmaceuticals, cosmetics, and electronic products. In the food industry, it can be used for moisture-proof labeling on packaging; In the pharmaceutical industry, it can be used for anti-counterfeiting labeling on drug packaging; In the electronics industry, it can be used for labeling information such as serial numbers and barcodes on products. In summary, aluminum foil adhesive labels have become a highly favored label product in the market due to their unique material, excellent performance, wide range of applications, and environmentally friendly features.

Copperplate paper adhesive label

Copperplate paper adhesive labels, as a type of adhesive label that uses copperplate paper as the surface material, occupy an important position in the label industry due to their unique smooth surface and excellent printing effect. This type of label is widely used in various industries and fields due to its elegant appearance and excellent performance.

The main feature of copperplate paper adhesive labels is their smooth and shiny surface. This surface makes the label more attractive and can effectively enhance the product's grade and added value. At the same time, the fiber distribution of copperplate paper is uniform and the tightness is moderate, which makes the label have good flatness and deformation resistance, and can maintain a stable shape even in humid or high temperature environments.

In addition to its unique appearance, copperplate paper adhesive labels also have excellent printing effects. Its surface is smooth and delicate, capable of presenting exquisite patterns and text, making the label more eye-catching and easy to identify. Whether printed in monochrome or multi-color, copperplate paper adhesive labels can exhibit excellent color saturation and clarity.

Copperplate paper adhesive labels are widely used in various industries and fields such as food, beverage, medicine, daily chemical, electronics, etc. In the food industry, it can be used to label information such as production date and shelf life on packaging; In the pharmaceutical industry, it can be used for printing explanatory text and patterns on drug packaging; In the electronics industry, it can be used for labeling information such as serial numbers and barcodes on products.

Advantages and disadvantages of copperplate paper adhesive labels

Copperplate paper adhesive labels, as a widely used type of label, are highly favored for their unique smooth surface and excellent printing effect. However, just like any product, copperplate paper adhesive labels also have their advantages and disadvantages.

In terms of advantages, the surface of copperplate paper adhesive labels is smooth and shiny, making the labels more attractive and effectively enhancing the product's grade and added value. Its fiber distribution is uniform, with moderate tightness. The label has good flatness and deformation resistance, and can maintain a stable shape even in humid or high-temperature environments. In addition, the printing effect of copperplate paper adhesive labels is excellent, presenting exquisite patterns and text, with excellent color saturation and clarity. This makes copperplate paper adhesive labels widely used in various industries and fields such as food, beverage, medicine, daily chemical, electronics, etc.

However, copperplate paper adhesive labels also have some drawbacks. Due to its smooth surface, the adhesion between it and the adhesive surface may not be strong enough in some cases, making it prone to detachment. In addition, copperplate paper is relatively thin and may be easily damaged or deformed when subjected to external forces. Therefore, when choosing to use copperplate paper adhesive labels, it is necessary to consider the product's usage environment and whether strong adhesion and durability are required.

Common materials for silver PET adhesive labels

1. Light silver PET adhesive: slightly brighter than ordinary PET materials

2. Dumb silver PET adhesive: slightly darker than ordinary PET materials

3. Brushed silver PET adhesive: The material surface itself has regular stripes

If we add the adhesive characteristics of the adhesive and the material of the bottom paper of the adhesive label, then the silver PET adhesive label can be further subdivided

We offer comprehensive technical support, including free professional labeling solutions, advice on label materials and adhesive selection, as well as online/offline assistance from professional software and hardware engineers. Service email: andy@ownlikes.cn. In pre-sales, we leverage our extensive experience in specialty labeling projects to provide clients with the most suitable hardware solutions. Additionally, all our label barcode printers and scanners come with a three-year free warranty, demonstrating our confidence in our products.

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.