Materials used for daily chemical labels

The substrate of paper self-adhesive labels is mainly made of copperplate paper, and the brightness and waterproof function are enhanced through film coating treatment. The printing method is mainly offset printing for high-end products, and flexographic printing and screen printing for medium and low-end products. The main substrates for film adhesive labels are PE (polyethylene film), PP (polypropylene film), and various mixtures of PP and PE. Among them, PE material is relatively soft, with good followability and extrusion resistance, and is commonly used on bottle bodies that require frequent extrusion and are prone to deformation. PP material has high hardness and tensile resistance, suitable for printing, die-cutting, and automatic labeling, and is commonly used for harder transparent bottle bodies; Transparent label;. The polyolefin film mixed with PP and PE is both soft and resistant to compression, and has high tensile properties. It has good followability, printing and die-cutting, and automatic labeling, making it an ideal film type self-adhesive label material

1. Different materials are available for different bottle bodies to choose from

2. Suitable for various printing, hot stamping, and processing techniques

3 Suitable for various special bottle bodies, such as unique appearance contours

4. Soft plastic bottle body or hose that needs to be fully squeezed

5. Labels can remain intact and undamaged in humid and warm environments

6. Effectively combat the corrosion of the product itself

The problem of "oil penetration" after labeling hot melt adhesive materials

There was once a labeling company that processed a batch of labels for a daily chemical customer. After labeling, the labels gradually encountered problems similar to "oil penetration", that is, the labels seemed to be soaked in oil, and this phenomenon became increasingly serious over time. Originally, the adhesive used by this labeling company was hot-melt, and the material of the bottle being labeled happened to be PVC.

In fact, hot melt adhesive materials cannot be used to stick PVC bottles because the two will undergo a chemical reaction, thereby changing the chemical structure of the hot melt adhesive. The "oil penetration" phenomenon mentioned above is the result of the chemical reaction between hot melt adhesive and PVC material. Later, after a detailed investigation, it was found that this daily chemical enterprise had previously used water-based labels, and the chemical properties of the adhesive were relatively stable, without reacting with PVC materials, so there was no "oil penetration" problem.

This case highlights that the selection of label materials for daily chemical products is not only related to the type of surface material, but also to the type of adhesive used.

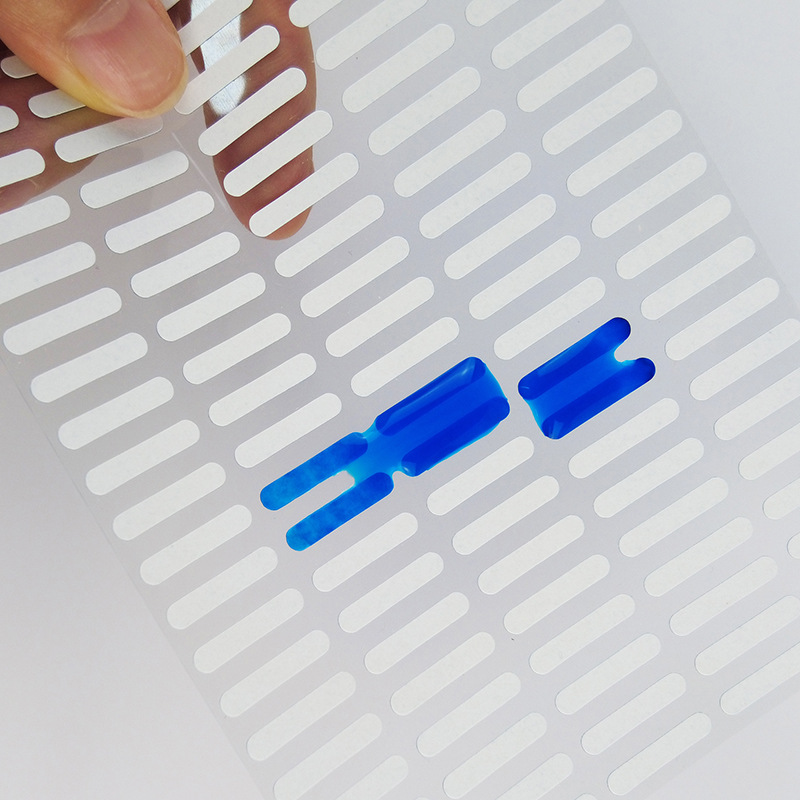

Eggshell paper adhesive material

Fragile paper adhesive labels are an important type of adhesive label, and their fabric fracture strength is much lower than the adhesive bonding ability. They have the characteristics of being unable to be completely peeled off and cannot be reused after being pasted. Fragile paper adhesive surface materials are processed through printing, die-cutting and other processes to produce fragile labels or fragile stickers, also known as product fragile warranty stickers. It is mainly used for unconventional product identification methods that are difficult to accurately guarantee with formal warranty methods

Fragile paper adhesive surface material is suitable for printing and processing in the form of roll barrel paper on label machines. Due to the low strength of the surface material, fragile paper only needs to be printed and die cut, without waste disposal; The finished product label is only sliced and not rewound. So fragile paper adhesive labels cannot be automatically labeled and are all manually labeled

Fragile paper:Transparent fragile, laser fragile, white fragile

Widely used in the quality assurance of high-end products such as mobile phones, telephones, computer accessories, automotive appliances, alcohol, drugs, food, cosmetics, and performance tickets, it can also be applied to anti-theft and tamper proof products in shopping malls. The characteristics of the guaranteed products are high price, large warranty responsibility, and high requirements for the accuracy of warranty dates. Therefore, the quality of fragile stickers is directly related to the quality of product after-sales service and the economic interests of merchants. The use of this anti-counterfeiting material can effectively avoid various losses and disputes

Water discoloration label

Water color changing labels, also known as water sensitive warning anti-counterfeiting adhesive labels or water sensitive labels, waterproof labels, or water color changing labels. This label material will change color completely when it comes into contact with water, and the color is irreversible. It is a new type of product developed for the purpose of providing maintenance services for products such as mobile phones, batteries, electronics, appliances, LCDs, etc. that are difficult to identify or incorrectly identify when damaged by water, and control that does not meet the conditions. It is also designed to identify water ingress in goods transported by sea and provide legal basis for claims. The main function of water sensitive anti-counterfeiting labels is that when the substrate is completely exposed to water, the surface will change to a color that is significantly different from before and irreversible. Therefore, the changed color can be any other color specified by the customer.

We offer comprehensive technical support, including free professional labeling solutions, advice on label materials and adhesive selection, as well as online/offline assistance from professional software and hardware engineers. Service email: andy@ownlikes.cn. In pre-sales, we leverage our extensive experience in specialty labeling projects to provide clients with the most suitable hardware solutions. Additionally, all our label barcode printers and scanners come with a three-year free warranty, demonstrating our confidence in our products.

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.