PVC adhesive material

PVC is the English abbreviation for vinyl. It is also a polymer material. The common colors for PVC label materials are sub white, pearl white, and transparent. The performance of polyvinyl chloride adhesive is similar to that of polyethylene adhesive labels. It has better flexibility and soft feel than polyethylene label paper. Commonly used in high-end occasions such as jewelry, watches, electronics, and metal. However, the degradation of polyvinyl chloride label materials is poor, which has a negative impact on environmental protection. Some developed countries abroad have begun to develop this alternative

PVC adhesive labels are composed of four parts: surface material, adhesive, backing paper, and printing ink. The common color tones include sub white, pearl white, and transparent. PVC adhesive labels have similar performance indicators to PET adhesive labels. They have better flexibility and a soft touch than PET adhesive labels, and are often used in high-end places such as jewelry, accessories, clocks, electronics, and metal materials. However, the solubility of PVC label materials is relatively poor, which has a negative impact on ecological environment protection. PVC adhesive labels are waterproof, moisture-proof, oil resistant, tear resistant, and heat-resistant, and are commonly used in manufacturing industries such as electronic devices, household appliances, automobiles, and chemical plants

PVC has non flammability, high strength, resistance to climate change, and excellent geometric stability. It has strong resistance to oxidants, reducing agents, and strong acids. In addition, due to its excellent flexibility, shrinkage, and opacity, as well as good processing and labeling performance, strong chemical corrosion resistance, and durability, it is suitable for long-term outdoor use

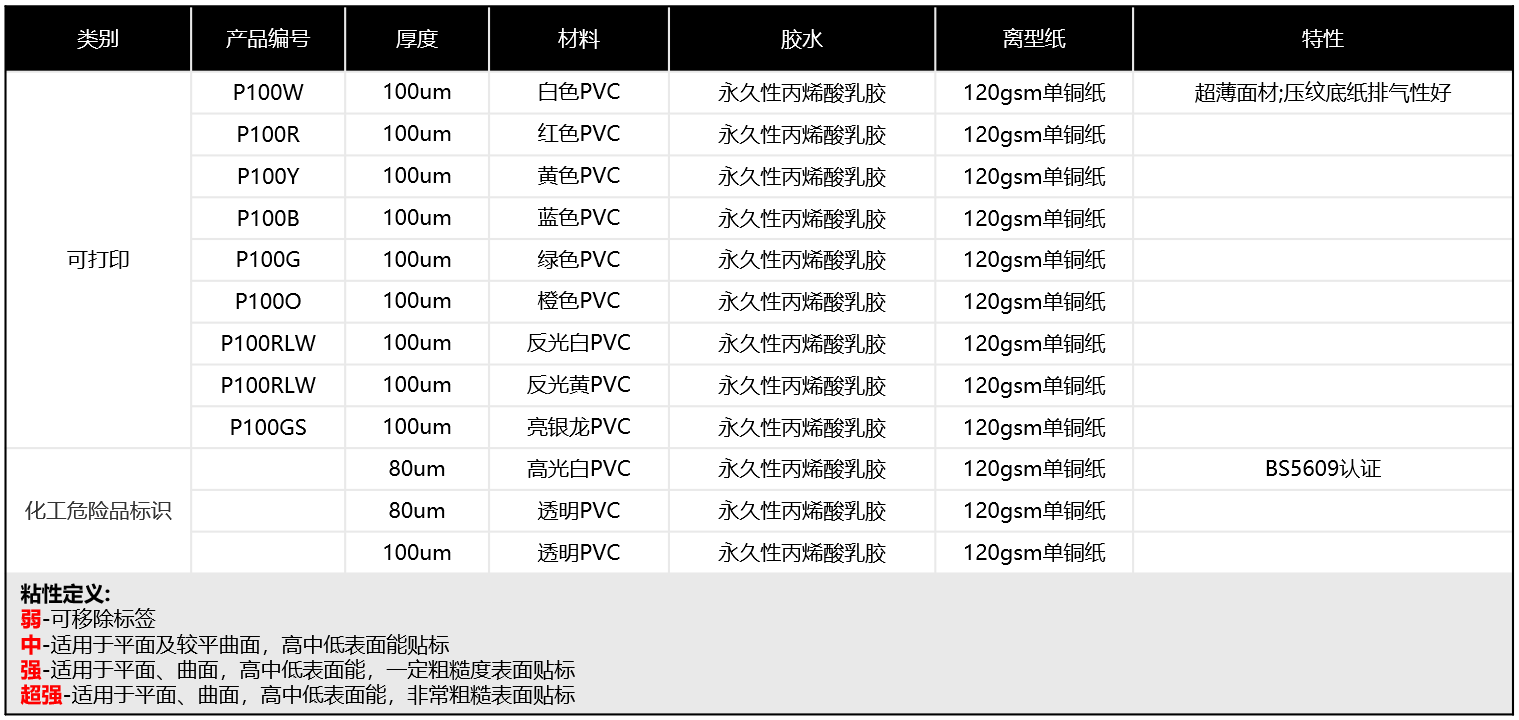

PVC series adhesive material list

Can PVC adhesive material be paired with hot melt adhesive?

PVC adhesive material can be used in combination with hot melt adhesive

PVC (polyvinyl chloride) adhesive material has good stability and adhesion, while hot melt adhesive is a type of glue that is melted by heating and coated on the material to achieve adhesion

However, whether to choose to use hot melt adhesive combined with PVC adhesive material still needs to consider specific application scenarios and requirements. Here are some factors that may need to be considered:

Adhesive strength requirements:The adhesive strength of hot melt adhesive varies depending on the formula and process.. When choosing hot melt adhesive, it is necessary to ensure that its adhesive strength can meet the application requirements of PVC adhesive materials

Usage environment:Different usage environments have different performance requirements for hot melt adhesive and PVC adhesive materials.. For example, in high temperature or high humidity environments, it is necessary to choose hot melt adhesive and PVC adhesive materials that are resistant to high temperature and humidity

Process compatibility:The coating process of hot melt adhesive needs to be compatible with the processing technology of PVC adhesive material.. For example, if PVC adhesive materials need to be processed through printing, cutting, and other processes, it is necessary to ensure that the application of hot melt adhesive does not have adverse effects on these processes

Cost considerations: The cost of hot melt adhesive and PVC adhesive materials is also a factor to consider. When choosing a combination for use, it is necessary to comprehensively consider cost-effectiveness and practical application needs

Can PVC adhesive labels be waterproof?

PVC adhesive labels have certain waterproof properties, but their effectiveness is affected by factors such as glue, printing process, and surface treatment. Waterproof coating or ink can enhance the waterproof effect, but it is not permanent and will weaken over time.

The usage environment and conditions also affect the waterproof performance.

Therefore, when choosing, it is necessary to evaluate the waterproof effect based on specific needs and the environment.

Is there any difference between PVC adhesive material and thermal paper adhesive material?

PVC adhesive material belongs to the category of film materials, with characteristics such as waterproofing, oil resistance, strong weather resistance, and high temperature resistance. Thermal paper belongs to the category of paper materials, including ordinary thermal paper, three proof thermal paper, and long-lasting thermal paper. Let's get to know each other together

1. PVC Adhesive Material

Widely applicable to label production in electronics, gift crafts, hardware, toys, plastic factories, machinery, food, and clothing. Specifications can be customized according to customer requirements, and printing forms are diverse: screen printing, color printing, offset printing, etc

Advantages: It has non flammability, high strength, resistance to climate change, and excellent geometric stability, and has strong resistance to oxidants, reducing agents, and strong acids. In addition, due to its excellent flexibility, shrinkage, and opacity, as well as good processing and labeling performance, strong chemical corrosion resistance, and durability, it is suitable for long-term outdoor use

Disadvantages: PVC has poor thermal stability and light resistance, and can begin to decompose and release hydrogen chloride (HCl) gas above 140 ℃, which is not conducive to environmental protection (alkaline stabilizers and HCl are often added in actual production to inhibit its catalytic cracking reaction). In addition, some toxic auxiliary materials such as plasticizer and anti-aging agent are added in the manufacturing process to enhance its heat resistance, toughness, ductility, etc., so its products generally do not store food and drugs. In addition, PVC label materials have poor biodegradability and have a negative impact on environmental protection

2. Thermal paper adhesive material

Thermal sensitive paper is a type of self-adhesive label paper. The surface paper of this label paper is treated with a high thermal sensitivity thermal sensitive coating, and there is a glue layer behind the paper for adhesion and fixation. The bottom layer is a base paper to protect the glue layer. After printing, the base paper can be torn off and used. The base paper is divided into ordinary blue base, white base, and imported Gracin base. Ordinary thermal paper is not waterproof, oil resistant, and tear resistant. Three proof thermal paper, waterproof, oil resistant, and friction resistant

Thermal adhesive stickers are suitable for various industries, such as supermarkets, restaurants, hotels, banks, telecommunications networks, medical institutions, and small and medium-sized fruit supermarkets. Considering that it does not need to be used in combination with carbon ribbons, it is both convenient and cost-effective

What are the suitable adhesive label materials for outdoor use?

If the label is located outdoors, continuous exposure to direct sunlight may be a challenge for label application, as ultraviolet radiation can cause the label to crack, peel off, and fade. Determine the label material to be used. The first thing to determine is the service life of the adhesive label. If the usage time is short, you can use lower priced self-adhesive materials such as paper. For anything that exceeds several months, we recommend using durable and weather resistant materials. Like PVC and PET materials, they can withstand freezing to high temperatures (-20 to 200 degrees) as well as other factors such as sunlight, chemicals, and wear and tear

1. PVC Adhesive Label Material

PVC adhesive labels are a type of polymer material that is non flammable, has high strength, is resistant to climate change, and has good geometric stability. PVC adhesive labels have strong antioxidant, reducing agent, and strong acid capabilities. Good flexibility, good shrinkage and opacity, good label processing, strong chemical resistance, durability, suitable for long-term outdoor use. It is widely used in the production of special materials such as trademarks, labels, clothing, curtains, holographic anti-counterfeiting, etc

2. PET Adhesive Label Material

PET is actually a polymer material, also known as polyester film. PET adhesive is waterproof, oil resistant, and not easily torn. Suitable for outdoor labels, it can resist corrosion from chemicals such as acid and alkali in harsh environments. Widely used as labels for high-performance products, such as toiletries, cosmetics, jewelry, and various motor products. Has good weather resistance, scratch resistance, high temperature resistance, and natural degradation performance. Therefore, it has become the preferred choice for many manufacturers

We offer comprehensive technical support, including free professional labeling solutions, advice on label materials and adhesive selection, as well as online/offline assistance from professional software and hardware engineers. Service email: andy@ownlikes.cn. In pre-sales, we leverage our extensive experience in specialty labeling projects to provide clients with the most suitable hardware solutions. Additionally, all our label barcode printers and scanners come with a three-year free warranty, demonstrating our confidence in our products.

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.