Sterilization indicator tape and indicator card

Sterilization indicator tapes and cards are tools used to verify whether medical equipment and instruments have been thoroughly sterilized. They indicate whether the equipment or instruments have been sterilized by changing color or through other signals. In the medical industry, sterilization indicator tapes and cards are indispensable devices.

Sterilization indicator tape is made by depositing sterilization indicators onto a special paper substrate. When the steam in the sterilized instrument reaches a certain temperature, the sterilization indicator will change color, making it easy to check whether the sterilization goal has been achieved.

The usage of sterilization indicator tape is very simple. Just attach it to the instrument that needs to be sterilized and place it in the sterilizer for sterilization. After sterilization, remove the sterilization indicator tape for inspection. If the indicator color has changed, it indicates that sterilization has been successful.

Sterilization indicator cards are similar to sterilization indicator tapes and are generally made of one or more indicators. However, the difference is that sterilization indicator cards require the use of a vacuum sterilizer because only in a vacuum sterilizer can both temperature and pressure reach the specified requirements.

The usage of sterilization indicator cards is slightly more complex than that of sterilization indicator tapes. First, place the sterilization indicator card in the sterilizer for sterilization. After sterilization, remove the sterilization indicator card and use a special card reader to read it. The reading result will show whether the sterilization indicator card has changed color, thereby determining whether sterilization has been successful.

Pressure steam sterilization indicator tape

Pressure Steam Sterilization Indicator Tape, also known as Autoclave Indicator Tape, is specifically designed to be adhered to the exterior of packages containing items to be sterilized. It serves as an indication of whether the package has undergone pressure steam sterilization, preventing confusion with unsterilized packages.

The product is made with medical-grade crepe paper as the base material, coated with color-changing ink as the sterilization indicator, and backed with pressure-sensitive adhesive. It is exclusively used for adhering to the exterior of packages containing items to be sterilized, serving as a clear indication of whether the package has been through the pressure steam sterilization process.

Scope of Application: Suitable for use with downward displacement pressure steam sterilizers and prevacuum pressure steam sterilizers to indicate whether the item package has undergone pressure steam sterilization.

Usage Instructions: Cut a suitable length of indicator tape and affix it to the seal or surface of the package containing items to be sterilized (for better visibility, a longer length can be used, or the tape can be wrapped around the package in a spiral pattern). Then, place the package in a downward displacement pressure steam sterilizer at 121°C for 20 minutes or in a prevacuum pressure steam sterilizer at 132°C for 4-6 minutes. After sterilization, the diagonal indicator mark on the tape will change from light yellow to black, indicating that the package has been sterilized. The sterilization status and records can be directly written on the back of the indicator tape.

Disinfection and sterilization indicator tape

Sterilization indicator tape is a product used to indicate the sterilization process. It utilizes indicator ink on the tape that changes color after undergoing sterilization, allowing for the determination of whether an item has been sterilized or not. This provides a straightforward and convenient way to assess the sterilization status of the item.

Commonly used sterilization methods include high-pressure steam sterilization, ethylene oxide sterilization (EO sterilization), and plasma sterilization.

Medical sterilization indicator tape is a product specifically designed for the medical field to indicate the sterilization process. It utilizes indicator ink on the tape that changes color after undergoing sterilization, enabling the determination of whether a medical item has been sterilized or not. This provides a straightforward and convenient means of reflecting the sterilization status of the medical item.

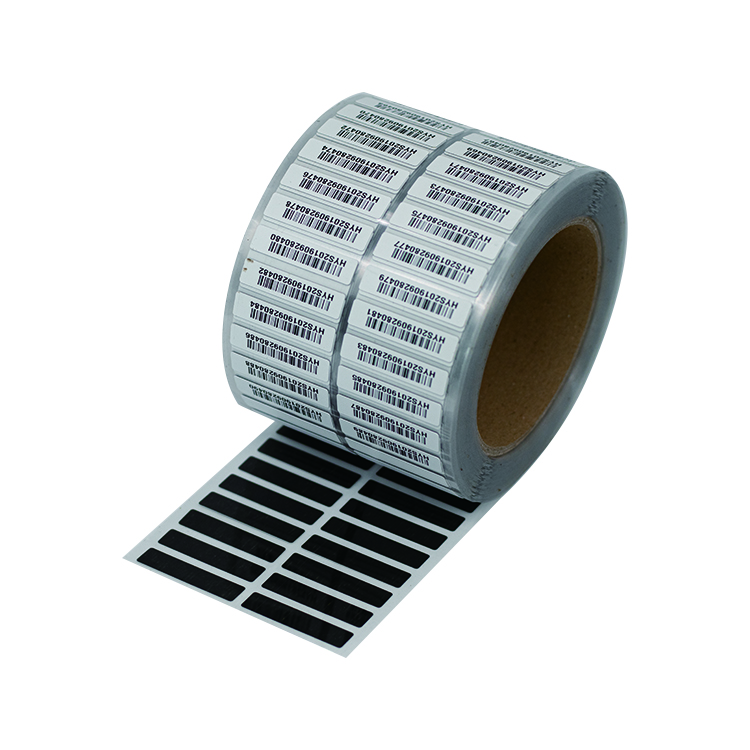

Pressure steam sterilization indicator label

The indicator label used for chemical monitoring outside pressure steam sterilization packages will change from light yellow to black on the crepe paper base when certain sterilization conditions are met, such as 121℃ for 20 minutes or 132℃ for 3 minutes.

Uses:

-

It is used to indicate whether the item package has been treated through a pressure steam sterilization process.

-

If the color change is uneven or incomplete, it suggests that the package has not undergone sterilization under the required conditions.

-

It can record sterilization information (such as the operator, sterilization expiration date, names of items inside the package, sterilization batch number, etc.).

Types:

-

Single indicator label;

-

Roll indicator label;

-

Traceable indicator label.

The sterilization principle of high-temperature sterilization indicator labels

High-temperature sterilization indicator labels, also known as thermal indicator labels, are important tools widely used in medical, pharmaceutical, and biological laboratory fields. These labels are typically made from a special type of thermally sensitive material that changes color when exposed to specific high-temperature environments, thereby indicating whether the sterilization process has been completed. This article will delve into the working principle of high-temperature sterilization indicator labels and their applications in various fields.

The core working principle of high-temperature sterilization indicator labels is based on the color-changing properties of thermally sensitive materials. These thermally sensitive materials are usually composed of one or more chemical substances that undergo chemical reactions at specific temperatures, leading to color changes. This color change is typically irreversible, so once the label changes color, it is clear that the sterilization process has been completed.

We offer comprehensive technical support, including free professional labeling solutions, advice on label materials and adhesive selection, as well as online/offline assistance from professional software and hardware engineers. Service email: andy@ownlikes.cn. In pre-sales, we leverage our extensive experience in specialty labeling projects to provide clients with the most suitable hardware solutions. Additionally, all our label barcode printers and scanners come with a three-year free warranty, demonstrating our confidence in our products.

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.