Usage method of intelligent temperature measurement patch

1. The ZCW series intelligent color changing temperature measuring patch is in the form of a label. As long as the appropriate rated temperature color changing temperature measuring patch is selected, it can be directly pasted on the parts that need to be monitored for temperature, such as busbar joints, knife switches, transformer housings, etc. The temperature measurement patch should be pasted on a flat, clean, and dry surface, and should be firmly pressed when pasting.

2.If you want to know the gradual increase in temperature at the monitoring location during use, you can stick two or more color changing temperature measuring patches with different rated temperatures, or use ZCW-6575 patches.

3. Precautions:

a. The pasting of color changing temperature measuring patches should be carried out when there is no power on the busbar or other temperature monitoring parts, and safety regulations must be followed. If you want to paste temperature measurement patches with electricity, you must use insulation rods of the corresponding level to assist in pasting.

b. The intelligent color changing temperature measurement patch cannot be used in environments exposed to sunlight.

Wire and cable temperature sensing stickers

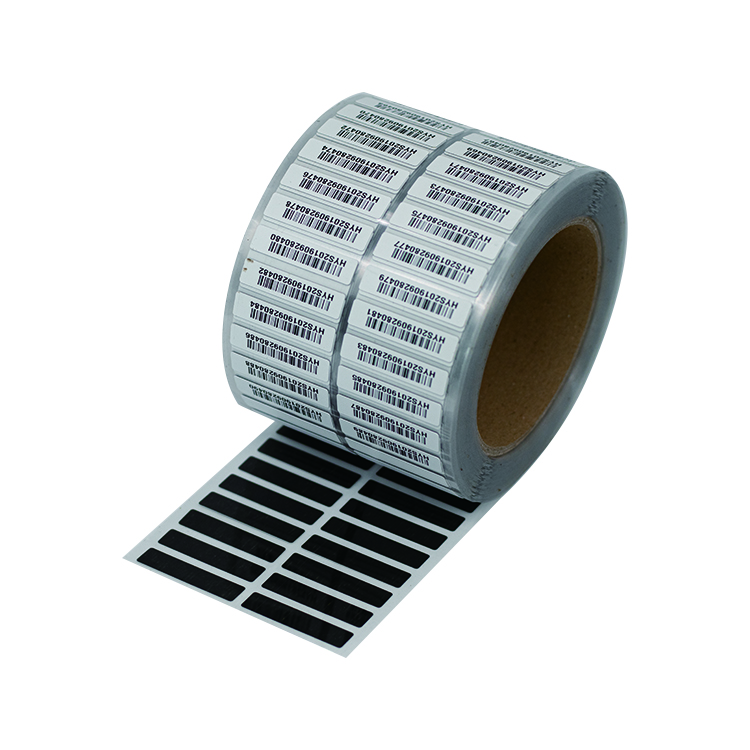

The specialized temperature sensitive stickers for railway passenger car wires and cables are produced in accordance with the TJ/CL442-2015 "Interim Technical Conditions for Temperature Sensitive Stickers for Railway Passenger Car Wires and Cables" standard of China Railway Corporation, and have passed the quality inspection of national authoritative institutions. The product has good flexibility, strong adhesion, easy adhesion, and irreversible color change after overheating. It has a recording function.

The specialized temperature sensitive sticker for railway passenger car wires and cables is produced in accordance with the TJ/CL442-2015 "Interim Technical Conditions for Temperature Sensitive Stickers for Railway Passenger Car Wires and Cables" standard of China Railway Corporation. This temperature sensitive sticker has unique color changing and digital display functions, and comes with adhesive. It is widely used in the control cabinets (distribution cabinets, electrical comprehensive control cabinets, air conditioning control cabinets, power conversion boxes, lighting control boxes), circuit breakers, contactors, thermal relays, fuses, and other connection parts of various types of air-conditioned passenger cars (including high-speed trains, bullet trains, and subways) on railways to monitor the temperature of the connection parts with wires and cables.

Once the temperature of the temperature monitoring area reaches or exceeds the rated temperature of the temperature sensing sticker, the sticker immediately changes from white to black. The sticker with a large color change area will also display the number of overheating at that location. Due to the irreversible color change of the temperature sensing sticker for railway passenger car wires and cables, it is easy for people to detect the temperature rise in the monitoring area during inspection, thereby identifying potential faults and preventing accidents from occurring.

The temperature sensitive stickers specifically designed for railway passenger car wires and cables produced by our company have excellent flexibility and strong adhesion, and can be firmly attached even on small cylindrical surfaces of wires and cables.

Instructions for using temperature sensitive stickers for wires and cables

1. The specialized temperature sensing sticker for railway passenger car wires and cables is in the form of a label. As long as an appropriate rated temperature sensing sticker is selected, it can be directly pasted on the temperature monitoring parts such as the wire and cable connection points of the air-conditioned passenger car control cabinet. The area where the temperature sensitive sticker is to be pasted should be clean and dry, and it should be firmly pressed when pasting.

2. If you want to know the temperature gradually rising in the monitoring area during use, you can stick temperature sensitive stickers with two or more rated temperature points.

3. Precautions: The pasting of temperature sensitive stickers should be carried out when there is no electricity in the wires, cables or other temperature monitoring areas, and safety regulations must be followed.

What is the service life of temperature sensitive stickers?

The lifespan of temperature sensitive stickers is influenced by various factors, making it difficult to provide a unified answer. Generally speaking, temperature sensitive stickers can have a relatively long lifespan when stored in a suitable environment without exceeding the temperature limit. For example, some brands of temperature measuring patches can be stored for 4-5 years or even longer when used in normal environments at room temperature. However, in complex and harsh environments such as industrial sites, the service life of temperature sensitive stickers may be shortened due to factors such as large temperature fluctuations and mechanical damage. Therefore, many manufacturers stipulate that as long as the temperature sensitive stickers remain white and do not exceed the temperature limit, they can be used for 2-3 years.

The service life of temperature sensitive stickers is also related to factors such as their material and production process. Some high-quality temperature sensitive stickers use advanced materials and processes, which can maintain a longer service life in more harsh environments.

Is the service life of temperature sensitive stickers related to temperature?

The temperature sensitive stickers are embedded with special temperature sensitive materials inside, which are extremely sensitive to temperature and can undergo color changes at specific temperatures, thus intuitively reflecting the temperature changes. However, this temperature sensitive material is not permanently unchanged, and its performance gradually deteriorates with changes in time and temperature. In high temperature environments, the temperature sensitive material of temperature sensitive stickers may accelerate aging, leading to a decrease in temperature measurement accuracy of the stickers, or even complete failure.

The service life of temperature sensitive stickers is greatly affected by temperature. In order to maintain the accuracy and reliability of the stickers, users should try to avoid exposing them to high temperature environments beyond the rated temperature range and follow the product instructions for proper use and storage. At the same time, regularly replacing temperature sensitive stickers is also an important measure to ensure the accuracy of temperature measurement.

We offer comprehensive technical support, including free professional labeling solutions, advice on label materials and adhesive selection, as well as online/offline assistance from professional software and hardware engineers. Service email: andy@ownlikes.cn. In pre-sales, we leverage our extensive experience in specialty labeling projects to provide clients with the most suitable hardware solutions. Additionally, all our label barcode printers and scanners come with a three-year free warranty, demonstrating our confidence in our products.

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.