What are the specific types of PVC adhesive materials?

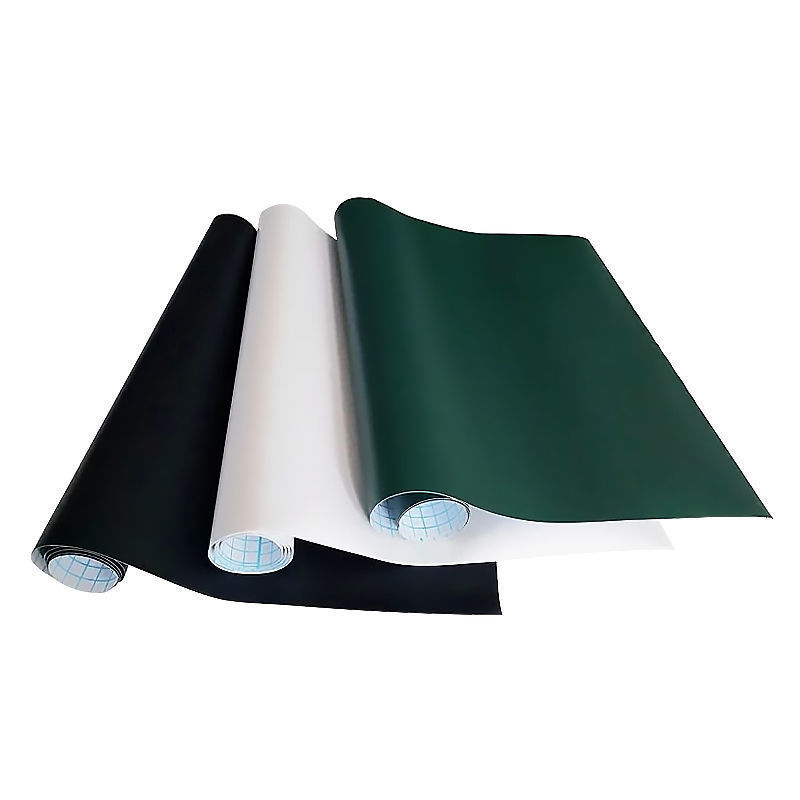

PVC adhesive material, like PET adhesive, is also a type of polymer material. The common colors of PET materials include matte silver, bright silver, bright gold, sub white, bright white, sub black, and bright black. Unlike it, PVC adhesive materials come in a wide variety of colors, which can be said to be colorful. Let's get to know each other in detail together.

The common colors of PVC label materials include sub white, pearl white, and transparent. PVC adhesive and PET adhesive labels have similar performance, with better flexibility and a soft touch than PET label paper. They are often used in high-end occasions such as jewelry, watches, electronics, and metal industries. However, the degradation of PVC label materials is poor, which has a negative impact on environmental protection. Some developed countries abroad have begun to develop alternative products in this area.

PVC (polyvinyl chloride) has two types: soft and hard, with good durability, tear resistance, flexibility, and chemical corrosion resistance. It is widely used in electronics, machinery, batteries, and outdoor applications. But the temperature resistance and tensile strength are generally average, and there will be a certain degree of shrinkage under the influence of temperature. Easy to tear off when stretched. Due to environmental restrictions, indoor use is becoming increasingly rare.

The commonly used thickness of PVC is 80u, and different adhesives can be used according to different application needs. There are water-based glue, hot glue, oil-based glue, removable glue, etc. The base paper can be paired with Grassin base, white thick base, etc.

PVC self-adhesive label

The temperature resistance range of general PVC labels is -10℃ to +60℃, with a minimum label application temperature of 10℃;

For high-adhesion PVC labels, the temperature resistance range is -20℃ to +80℃, with a minimum label application temperature of 7℃;

High-temperature PVC labels have a temperature resistance range of -20℃ to +280℃ (withstanding 280℃ for 10 minutes and 320℃ for 10 seconds), and a minimum label application temperature of 7℃;

Ultra-low temperature PVC labels have a temperature resistance range of -196℃ to +165℃, with a minimum label application temperature of -40℃.

What adhesive materials should be used for durability labels?

Durability labels refer to labels that remain on objects for a long time without falling off. The surface adhesive material of the label requires good weather resistance and toughness, and the adhesive agent requires high bonding strength and durability. Thin film materials are usually the preferred choice for durability labels

1. PET Adhesive Material

The commonly used thicknesses are 25um and 50um, and the colors include bright white, matte white, transparent, and metalized bright silver, bright gold, matte gold, and matte silver

The characteristics of PET adhesive material are as follows

a. The material has high hardness, tensile strength, and tear resistance

b. Excellent high temperature resistance, capable of withstanding temperatures up to 150 ℃

c. Excellent durability

d. Excellent transparency, opacity, and good metallization properties

e. Good chemical corrosion resistance, suitable for outdoor use, and widely applicable

2. PVC Adhesive Material

It is softer and more stretchable than PET material, with a thickness generally above 80um and 100um. The commonly used colors are white and transparent

The characteristics of PVC adhesive material are as follows

a. Good weather resistance, suitable for outdoor use

b. The application temperature range is between 20~80 ℃, and it is not resistant to high temperatures

c. Very good durability and chemical corrosion resistance

d. Due to its good flexibility, it is suitable for application on various types of surfaces

3. Synthetic paper adhesive material

It is a new type of synthetic material with the common characteristics of film and paper, with a thickness of over 60um and generally only white

The characteristics of synthetic paper adhesive materials are as follows

a. Has excellent tensile and shear strength

b. It has printing adaptability similar to paper and is suitable for printing with various inks

c· Good durability and corrosion resistance, suitable for outdoor use

d. Widely applicable and can replace various metal signs

We offer comprehensive technical support, including free professional labeling solutions, advice on label materials and adhesive selection, as well as online/offline assistance from professional software and hardware engineers. Service email: andy@ownlikes.cn. In pre-sales, we leverage our extensive experience in specialty labeling projects to provide clients with the most suitable hardware solutions. Additionally, all our label barcode printers and scanners come with a three-year free warranty, demonstrating our confidence in our products.

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.