Disinfection and sterilization indicator tape

Sterilization indicator tape is a product used to indicate the sterilization process. It utilizes indicator ink on the tape that changes color after undergoing sterilization, allowing for the determination of whether an item has been sterilized or not. This provides a straightforward and convenient way to assess the sterilization status of the item.

Commonly used sterilization methods include high-pressure steam sterilization, ethylene oxide sterilization (EO sterilization), and plasma sterilization.

Medical sterilization indicator tape is a product specifically designed for the medical field to indicate the sterilization process. It utilizes indicator ink on the tape that changes color after undergoing sterilization, enabling the determination of whether a medical item has been sterilized or not. This provides a straightforward and convenient means of reflecting the sterilization status of the medical item.

Pressure steam sterilization indicator label

The indicator label used for chemical monitoring outside pressure steam sterilization packages will change from light yellow to black on the crepe paper base when certain sterilization conditions are met, such as 121℃ for 20 minutes or 132℃ for 3 minutes.

Uses:

-

It is used to indicate whether the item package has been treated through a pressure steam sterilization process.

-

If the color change is uneven or incomplete, it suggests that the package has not undergone sterilization under the required conditions.

-

It can record sterilization information (such as the operator, sterilization expiration date, names of items inside the package, sterilization batch number, etc.).

Types:

-

Single indicator label;

-

Roll indicator label;

-

Traceable indicator label.

The sterilization principle of high-temperature sterilization indicator labels

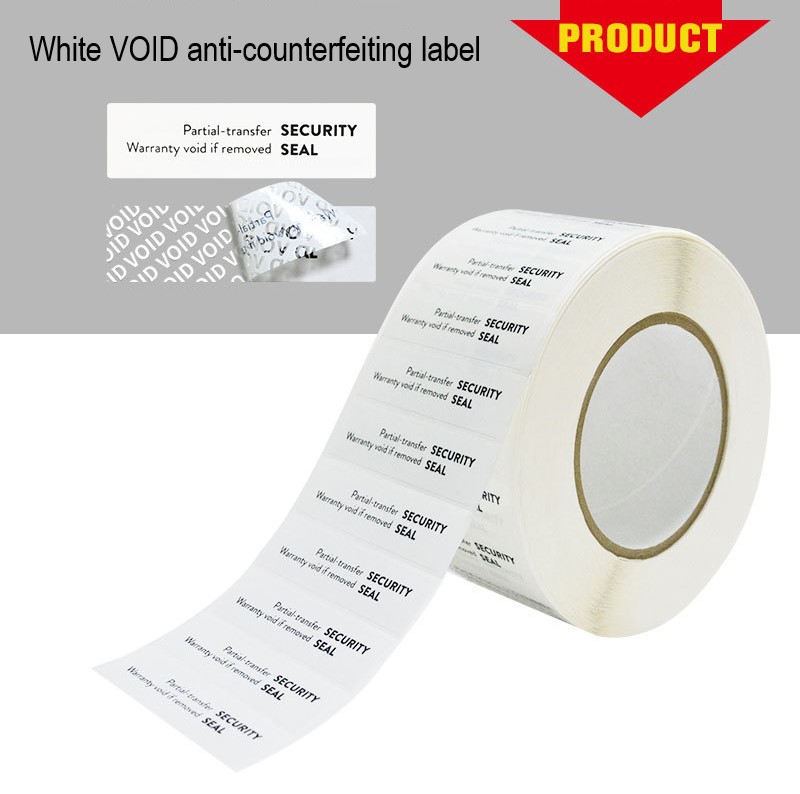

High-temperature sterilization indicator labels, also known as thermal indicator labels, are important tools widely used in medical, pharmaceutical, and biological laboratory fields. These labels are typically made from a special type of thermally sensitive material that changes color when exposed to specific high-temperature environments, thereby indicating whether the sterilization process has been completed. This article will delve into the working principle of high-temperature sterilization indicator labels and their applications in various fields.

The core working principle of high-temperature sterilization indicator labels is based on the color-changing properties of thermally sensitive materials. These thermally sensitive materials are usually composed of one or more chemical substances that undergo chemical reactions at specific temperatures, leading to color changes. This color change is typically irreversible, so once the label changes color, it is clear that the sterilization process has been completed.

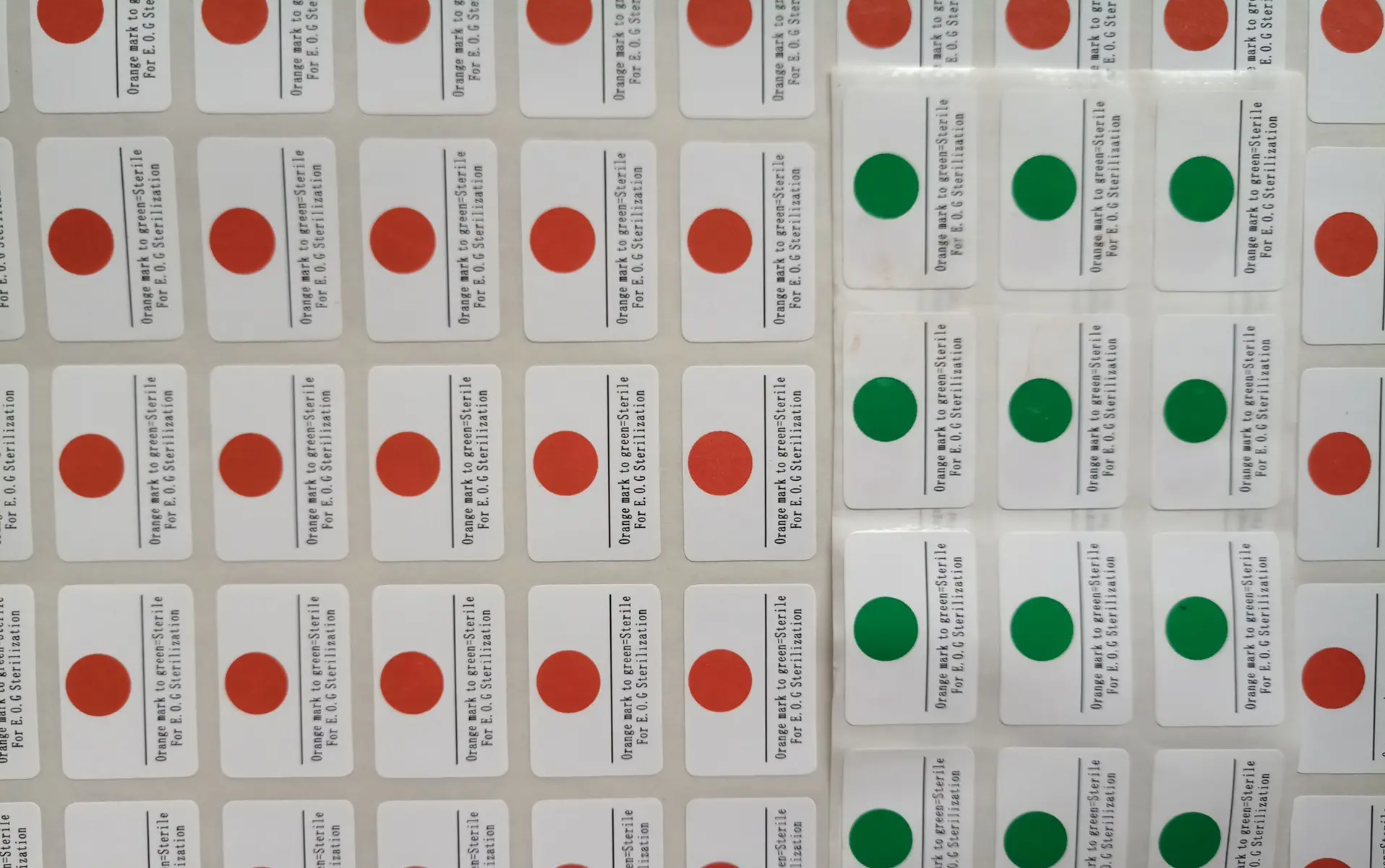

Sterilization color changing label

In today's packaging industry, the application of sterilization color-changing labels is receiving increasing attention. These labels not only provide effective sterilization protection but also indicate the sterilization status of packaging through color changes, offering consumers safer and more reliable packaging products.

Sterilization color-changing labels utilize special chemical reaction technology. When sterilization treatment is applied to the packaging, the label changes color based on the concentration and duration of the sterilizing agent. This color change effectively alerts operators to the sterilization status of the packaging, preventing incomplete or excessive sterilization due to human factors.

The advantages of sterilization color changing labels

-

Improving production efficiency: By indicating the sterilization status of packaging through color changes, it can reduce the time and cost of manual inspections, thereby improving production efficiency.

-

Enhancing product quality: Sterilization color-changing labels can effectively monitor the sterilization status of packaging, ensuring that products will not be contaminated by microorganisms during their shelf life, thus enhancing product quality.

-

Boosting consumer confidence: Consumers can judge the safety and reliability of products by observing the sterilization color-changing labels on the packaging, thereby boosting their confidence.

-

Facilitating regulatory supervision: Regulatory authorities can assess the sterilization status of products by checking the sterilization color-changing labels on the packaging, making it easier for them to conduct supervision and inspections.

We offer comprehensive technical support, including free professional labeling solutions, advice on label materials and adhesive selection, as well as online/offline assistance from professional software and hardware engineers. Service email: andy@ownlikes.cn. In pre-sales, we leverage our extensive experience in specialty labeling projects to provide clients with the most suitable hardware solutions. Additionally, all our label barcode printers and scanners come with a three-year free warranty, demonstrating our confidence in our products.

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.