Waterproof adhesive label

The advantages of waterproof adhesive label paper are good adhesion and not easy to peel off. Stamping neat, using stamping machines, easy to peel off, using special materials, easy to peel off. High quality materials, delicate surface materials, not easy to fade, good waterproofing, smooth printing, safe and environmentally friendly.

The purpose of waterproof label paper is for brochures such as maps, traffic maps, engineering drawings, etc. Various waterproof printing materials, glass cutting board stickers, etc. Disposable tableware, drinking utensils, etc. Has non-toxic characteristics. Various securities: can replace copperplate paper, with affordable prices. Advertisements, labels, business cards. It has the characteristics of bright color and durability. Packaging supplies: packaging boxes for tobacco, alcohol, tea, gift handbags, etc. It can be made into exquisite printing. Albums: such as product manuals, various samples, arts and crafts, etc.

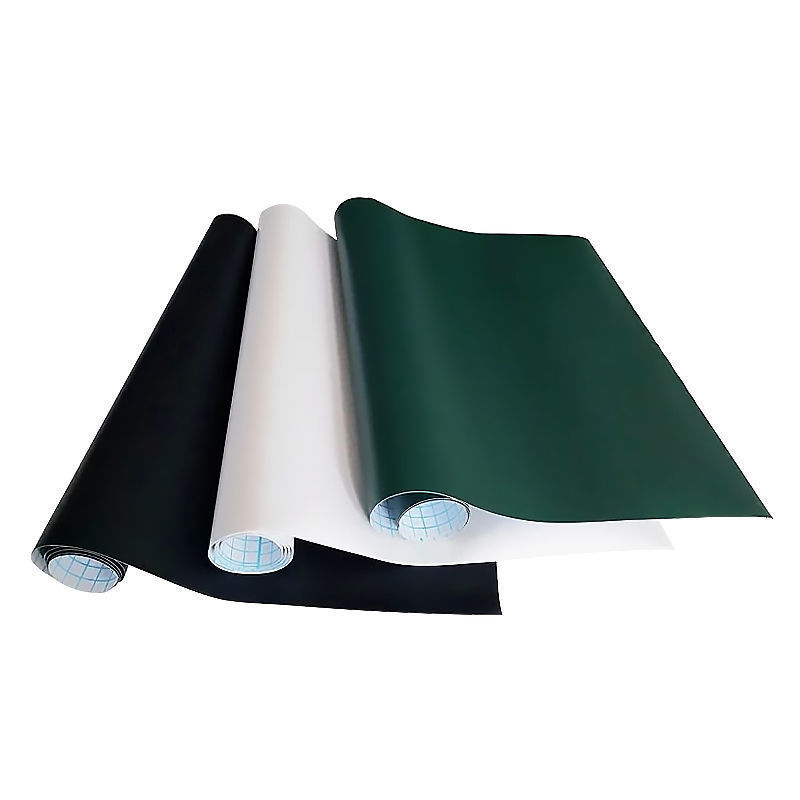

Waterproof label paper

Waterproof label paper refers to label paper with waterproof performance and strong tear resistance, usually made of PET material. For example, Asian silver paper labels, bright white PET labels, etc. These materials of label paper themselves have waterproof function. Of course, when choosing label paper, it is necessary to match the corresponding label printer in order to better utilize its performance.

Five advantages of waterproof adhesive label paper:

1. It has a certain degree of strong adhesion and will not easily peel off.

2. Stamping is neat and neat, using stamping machines

3. Different materials have different usage scenarios, and waterproof label paper made of special materials is easy to peel off.

4. High quality materials, delicate surface materials, and not easily faded

5. Strong waterproof, the handwriting will not be blurred even when washed with water, and it is safe and environmentally friendly

Durability label

A durability label consists of top coating, surface material, adhesive layer, release film, adhesive, and other components. Each layer of structure has different functions.

1. The surface material is the basic layer of the label. As the basic material for other layers, the surface material can provide strength, temperature resistance, chemical resistance, and other functions; There are multiple types of surface materials for labels. Paper surface materials have lower costs, but are not resistant to moisture and solvents; Plastic film, with excellent moisture and chemical resistance, is widely used in durability labels, especially PET film, which has high tensile strength and dimensional stability. PVC and PP materials have good adhesion. Polyimide and modified polyester have high temperature resistance, but they are expensive. Compare the characteristics of plastic film surface materials in 3M durability labels from four aspects: temperature resistance, outdoor durability, chemical resistance, and wearability. In practical applications, suitable surface materials can be selected based on factors such as usage environment and cost-effectiveness.

2. The top coating can increase ink adhesion and wear resistance; The top coating can firmly bond the surface layer and ink layer, not only improving the wear resistance and solvent resistance of the ink, but also creating various appearance effects such as matte and glossy. High performance topcoat is the key to achieving high-quality printing results.

3. Adhesive layer. The adhesive layer is an important structure to ensure that the label can be firmly attached.

The surface material, top coating, and adhesive layer are the core components of the entire durability label. Adhesive is also of utmost importance in durability labels.

We offer comprehensive technical support, including free professional labeling solutions, advice on label materials and adhesive selection, as well as online/offline assistance from professional software and hardware engineers. Service email: andy@ownlikes.cn. In pre-sales, we leverage our extensive experience in specialty labeling projects to provide clients with the most suitable hardware solutions. Additionally, all our label barcode printers and scanners come with a three-year free warranty, demonstrating our confidence in our products.

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.