An Overview of Pharmaceutical Adhesive Label Applications

Pharmaceutical adhesive labels play a critical role in the pharmaceutical industry, providing essential information and branding for various products. These labels are designed to meet specific requirements and standards to ensure product safety and compliance. In this article, we will categorize and explore the distinctive attributes pertaining to pharmaceutical adhesive label applications.

Categories of Pharmaceutical Adhesive Labels

Pharmaceutical adhesive labels can be categorized into several types based on their functions and applications:

1. Product Identification Labels

Product identification labels are perhaps the most common type in the pharmaceutical industry. They provide essential information such as the product name, dosage instructions, lot numbers, and expiration dates. These labels must adhere to strict regulatory requirements to ensure accuracy and patient safety.

2. Barcoded Labels

Barcoded labels contain unique barcodes that enable efficient tracking and inventory management in pharmaceutical facilities. These labels play a crucial role in preventing medication errors and ensuring the right product is administered to the right patient.

3. Warning Labels

Warning labels are designed to highlight critical information such as potential side effects, allergen warnings, and instructions for use. These labels are vital for ensuring patient safety and compliance with regulatory guidelines.

4. Tamper-Evident Labels

Tamper-evident labels are equipped with features that make it evident if the packaging has been tampered with. These labels help protect the integrity of pharmaceutical products, ensuring they have not been compromised during storage or transport.

Distinctive Attributes of Pharmaceutical Adhesive Labels

Each category of pharmaceutical adhesive label possesses distinctive attributes that cater to specific needs and requirements within the industry:

1. Material Selection

The choice of label material is critical in pharmaceutical applications. Labels must withstand various environmental factors, including exposure to moisture, temperature fluctuations, and chemicals. Common materials include paper, film, and synthetic materials like polypropylene or polyethylene, each with its own set of advantages and disadvantages.

2. Adhesive Properties

Adhesive properties are tailored to the label's intended use. Some labels require strong adhesion to prevent tampering, while others need easy removability for repackaging or repositioning. Adhesives must also adhere securely to various packaging materials, such as glass, plastic, or metal.

3. Regulatory Compliance

Pharmaceutical adhesive labels must adhere to strict regulatory guidelines set by organizations like the FDA. Compliance includes accurate representation of information, legibility, and the use of approved materials and inks to prevent contamination or adverse reactions with the product.

4. Printing Techniques

The printing techniques used for pharmaceutical adhesive labels can vary from standard flexographic or offset printing to digital printing for variable data and unique barcodes. High-quality printing ensures readability and barcode accuracy, critical for patient safety.

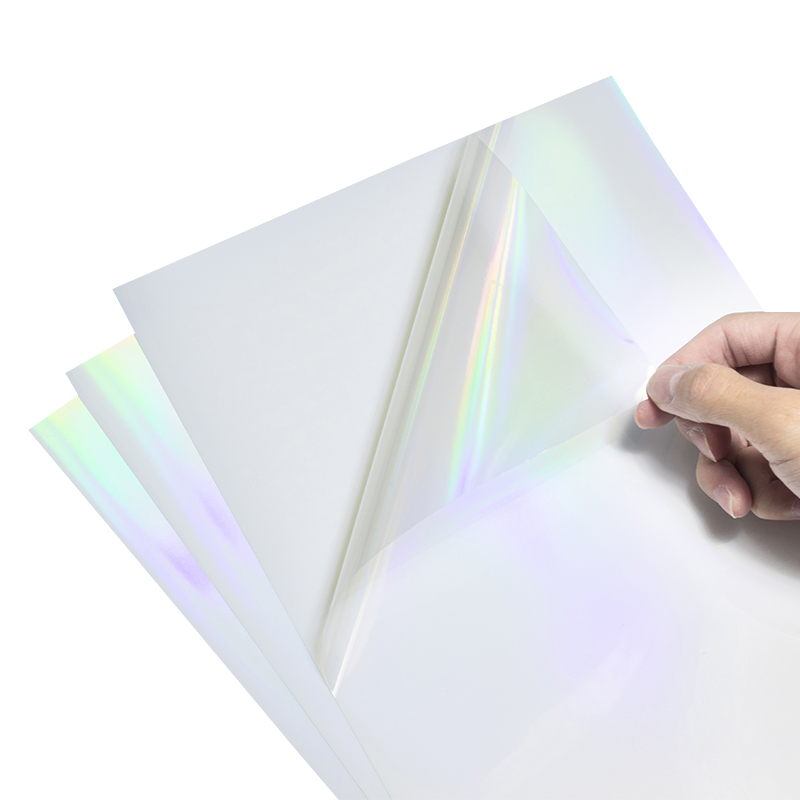

5. Security Features

Tamper-evident and anti-counterfeiting features are essential for pharmaceutical labels. These may include holographic elements, sequential numbering, or unique patterns that are difficult to replicate, helping to safeguard against counterfeit products.

Conclusion

Pharmaceutical adhesive labels are indispensable in the pharmaceutical industry, serving various functions to ensure product safety, compliance, and effective inventory management. Understanding the categorization and distinctive attributes of these labels is essential for pharmaceutical manufacturers and regulatory authorities to uphold the highest standards in patient care and safety.

For more information on pharmaceutical adhesive labels or to explore custom solutions for your specific needs, please contact our experts in the field.

We offer comprehensive technical support, including free professional labeling solutions, advice on label materials and adhesive selection, as well as online/offline assistance from professional software and hardware engineers. Service email: andy@ownlikes.cn. In pre-sales, we leverage our extensive experience in specialty labeling projects to provide clients with the most suitable hardware solutions. Additionally, all our label barcode printers and scanners come with a three-year free warranty, demonstrating our confidence in our products.

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.