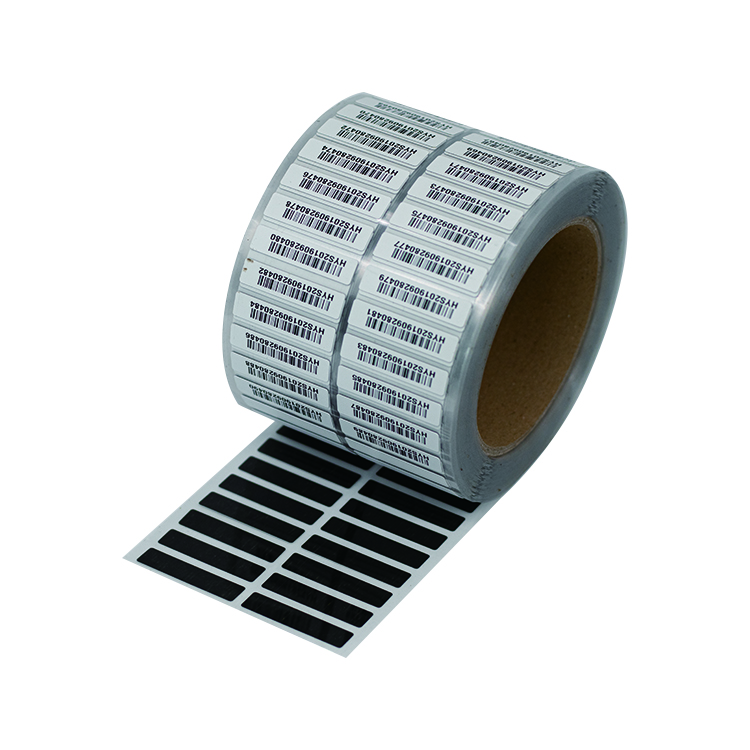

Car frame label

The car frame label is a 4mil white glossy PET with strong adhesive strength, which can be applied to various low and high surface energy plastics, painted metal parts

Car frame label Product parameters

Coating: White glossy surface

Thickness: 4mil

Substrate: PET

Temperature resistance range: -40 ° C; ℃ to 200℃

Certification standard: SGS/RoHS

Characteristics and Applications of Automotive Frame Labels

Stable temperature resistance, excellent printing effect, strong adhesion, oil resistance, chemical solvent resistance, moisture resistance, and good weather resistance

Mainly used for automotive and mechanical parts with oily surfaces, it can be used for automotive frames and accessories

Automotive airbag label

What is the mute white car airbag label; A white glossy matte airbag label that can be used on silicon surfaces and can be affixed with non-woven fabric, commonly used in the automotive industry

Dumb white car airbag label Product parameters

Coating: White matte surface

Thickness: 2mil

Substrate: PET Temperature range: -40 ℃ to 100 ℃

Certification standard: SGS/RoHS

Dumb white car airbag label Product features

Silicone bottom can be attached to rubber surface, with stable temperature resistance, chemical corrosion resistance, and waterproofing

Application of mute white car airbag label products

Suitable for silicon surfaces, such as airbags, silicon products can be coated with non-woven fabric

Can carbon ribbons be reused?

Carbon ribbon is a consumable used in printing and photocopying machines, which can be used to print text and images on paper. Its working principle is that during the printing process, the needles on the print head will print text and images onto the carbon ribbon according to the specified encoding method, and then transfer them to the paper through the carbon powder on the carbon ribbon to achieve the printing effect.

Generally speaking, carbon ribbons are disposable and are not recommended for repeated use, as it can gradually reduce the amount of carbon powder on the ribbon, affecting the blackness and clarity of printing, and increasing the risk of print head wear and ribbon damage. Therefore, it is recommended to replace the carbon ribbon with a new one in a timely manner when its lifespan expires or when there are quality issues.

We offer comprehensive technical support, including free professional labeling solutions, advice on label materials and adhesive selection, as well as online/offline assistance from professional software and hardware engineers. Service email: andy@ownlikes.cn. In pre-sales, we leverage our extensive experience in specialty labeling projects to provide clients with the most suitable hardware solutions. Additionally, all our label barcode printers and scanners come with a three-year free warranty, demonstrating our confidence in our products.

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.