What adhesive materials should be used for durability labels?

Durability labels refer to labels that remain on objects for a long time without falling off. The surface adhesive material of the label requires good weather resistance and toughness, and the adhesive agent requires high bonding strength and durability. Thin film materials are usually the preferred choice for durability labels

1. PET Adhesive Material

The commonly used thicknesses are 25um and 50um, and the colors include bright white, matte white, transparent, and metalized bright silver, bright gold, matte gold, and matte silver

The characteristics of PET adhesive material are as follows

a. The material has high hardness, tensile strength, and tear resistance

b. Excellent high temperature resistance, capable of withstanding temperatures up to 150 ℃

c. Excellent durability

d. Excellent transparency, opacity, and good metallization properties

e. Good chemical corrosion resistance, suitable for outdoor use, and widely applicable

2. PVC Adhesive Material

It is softer and more stretchable than PET material, with a thickness generally above 80um and 100um. The commonly used colors are white and transparent

The characteristics of PVC adhesive material are as follows

a. Good weather resistance, suitable for outdoor use

b. The application temperature range is between 20~80 ℃, and it is not resistant to high temperatures

c. Very good durability and chemical corrosion resistance

d. Due to its good flexibility, it is suitable for application on various types of surfaces

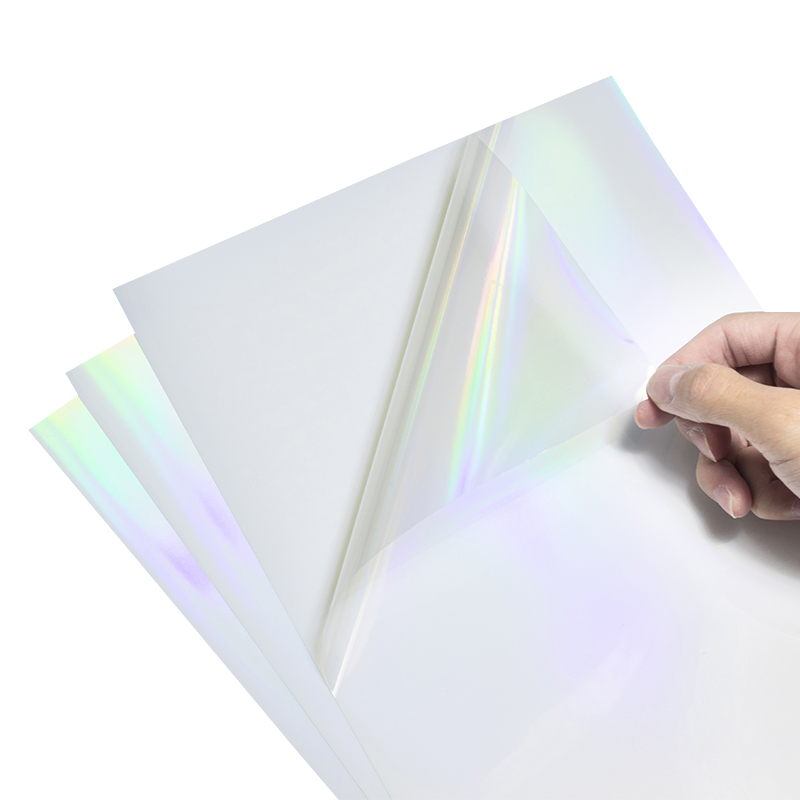

3. Synthetic paper adhesive material

It is a new type of synthetic material with the common characteristics of film and paper, with a thickness of over 60um and generally only white

The characteristics of synthetic paper adhesive materials are as follows

a. Has excellent tensile and shear strength

b. It has printing adaptability similar to paper and is suitable for printing with various inks

c· Good durability and corrosion resistance, suitable for outdoor use

d. Widely applicable and can replace various metal signs

PVC stickers, self-adhesive stickers

PVC adhesive stickers, also known as synthetic paper, have good chemical corrosion resistance and tear resistance, but their temperature resistance and tensile strength are generally affected by temperature; Widely used in applications such as electronics, machinery, batteries, outdoor stickers, etc. Due to the addition of many toxic additives during the production process of PVC labels, which are non recyclable and have poor biodegradability, they have a negative impact on environmental protection. So currently, the application of this label paper in the market is not as good as PET label paper.

PVC safety warning sticker

PVC safety warning stickers have low strength, average temperature resistance, poor tear resistance, and good transparency. But it has good flexibility, shrinkage, and opacity, good processing and labeling characteristics, can be used outdoors for a long time, and has excellent chemical corrosion resistance. Can be processed into various colors and glossy, matte, and metalized thin films. Generally, no surface treatment is required, suitable for various types of printing, especially for screen printing.

The fabric has important product labels such as transparent, glossy milky white, and matte milky white, which are resistant to water, oil, and chemicals. It is used for information labels of bathroom products, cosmetics, and electrical products, especially for high-tech resistant products;

PVC shrink film: suitable for battery trademark labels;

We offer comprehensive technical support, including free professional labeling solutions, advice on label materials and adhesive selection, as well as online/offline assistance from professional software and hardware engineers. Service email: andy@ownlikes.cn. In pre-sales, we leverage our extensive experience in specialty labeling projects to provide clients with the most suitable hardware solutions. Additionally, all our label barcode printers and scanners come with a three-year free warranty, demonstrating our confidence in our products.

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.