Characteristics of color changing temperature sensitive patches

Intuitiveness: Through color changes, users can quickly and intuitively assess temperature conditions without the need for additional measuring tools.

Diversity: Depending on application requirements, temperature-sensitive patches can be designed with different color change patterns, such as transitioning from blue to white, white to red, etc.

Convenience: The patch design allows for easy attachment and replacement, suitable for various surfaces.

Safety: Non-toxic and harmless, friendly to both humans and the environment, ensuring safe usage.

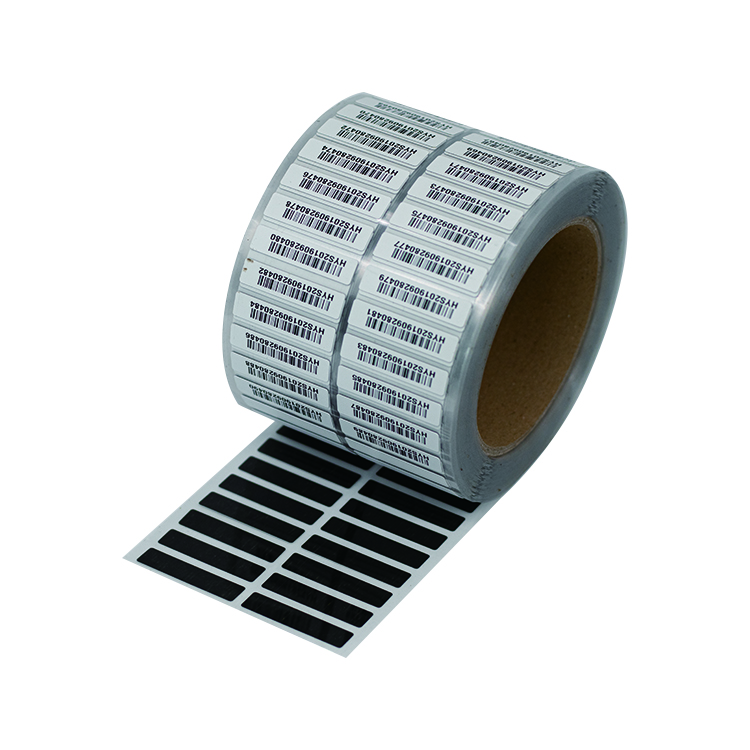

Corrosion resistant label

Corrosion resistant labels are special label materials designed to cope with various chemical corrosion environments. This type of label not only has excellent corrosion resistance to common chemicals such as acid and alkali, acetone, and washing water, but can also be customized for other corrosive chemicals according to specific customer needs, ensuring the stability and readability of the label in specific environments. Its material is mainly PET (polyethylene terephthalate), because PET material has excellent chemical stability, mechanical strength, and weather resistance, which can effectively resist the erosion of various chemical substances. In addition, the key to corrosion-resistant labels lies in their special coating and adhesive. Coating is the first line of defense to protect labels from chemical corrosion and must be able to withstand long-term corrosion. And glue is responsible for ensuring that the label can be firmly attached to the target object in various harsh environments, without falling off or losing its stickiness, thus ensuring the long-lasting and clear identification.

Corrosion resistant adhesive label

Corrosion resistant adhesive labels have the characteristics of acid and alkali resistance, corrosion resistance, chemical solvent resistance, high temperature resistance, moisture resistance, etc., and are widely used in harsh environments such as high temperature, high humidity, acid and alkali. Waterproof, corrosion-resistant, and high-temperature resistant materials and adhesives are commonly used, and have been tested to resist the corrosion of various chemicals such as bleach, brake fluid, alcohol, gasoline, diesel, acetone, isopropanol, MEK, petroleum solvent oil, penetrating oil, xylene, etc. Suitable for fields such as chemical engineering, industrial machinery, energy and power, underground pipeline networks, product traceability, logistics transportation, biological experiments, outdoor labeling, location patrols, and automotive engine labeling that require use in harsh environments such as high temperature, humidity, acidity, and alkalinity

Optional materials:PET, PVC, synthetic paper, etc

Label features:Corrosion resistant labels are waterproof, oil resistant, acid and alkali resistant, corrosion-resistant, resistant to chemical solvents, not easy to lift and fall off, with clear printing, bright colors, good glossiness, not easy to fade, smooth surface, uniform thickness, good flexibility, not easy to tear, etc

Application scope:Chemical and chemical engineering, industrial machinery, energy and power, underground pipeline network, product traceability, logistics transportation, biological experiments, outdoor identification, location patrol, automobile engine identification, etc

We offer comprehensive technical support, including free professional labeling solutions, advice on label materials and adhesive selection, as well as online/offline assistance from professional software and hardware engineers. Service email: andy@ownlikes.cn. In pre-sales, we leverage our extensive experience in specialty labeling projects to provide clients with the most suitable hardware solutions. Additionally, all our label barcode printers and scanners come with a three-year free warranty, demonstrating our confidence in our products.

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.