Requirements for sterilization labeling

The requirements for sterilization markings include the form, location, and content of the markings.

-

Form of markings: Sterilization markings typically appear in the form of graphics, text, or symbols to clearly indicate that the product has been sterilized.

-

Location of markings: Sterilization markings should be clear, easily identifiable, and placed in a visible location on the product packaging or container to ensure that consumers can easily see them.

-

Content of markings: Sterilization markings should include relevant information such as the sterilization method, date, batch number, etc., to provide information about the product's sterilization process.

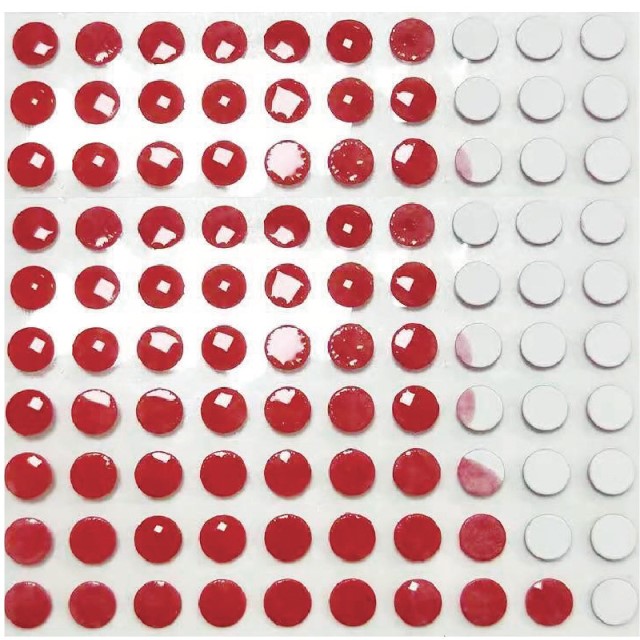

Gamma ray sterilization indicator label

Gamma Beta Gamma Beta Sterilization Indicator Label

Number: BYPS5031R

Purpose:

Adhesive labels change color when there are sufficient gamma (y) or beta (B) rays present.

Obvious and irreversible color change; Determine whether the item has been sterilized.

Application:

--Disinfection of medical products.

--When using gamma ray indicators for disinfection of packaging materials (bags in packaging boxes), products that have been exposed to radiation can be distinguished from those that have not.

Open gamma rays>5kgy, diameter 13mm, color change from yellow to red

Gamma rays>20kgy, diameter 13m, color change from yellow to red

Traceable sterilization indicator label

In compliance with the latest sterilization and disinfection standards, sterilization packages should have traceability. The "Traceable Sterilization Indicator Label" is used in conjunction with the corresponding "Sterilization Package Traceability Management System V1.0". Made of multi-layer materials, the label is pre-cut into two parts, divided into a "large label" and a "small label".

After sterilization, the supply room tears off the "small label" as a traceable record-keeping voucher, while the "large label" remains on the package and goes with the sterilized package. When a problem with the sterilized package is found, scanning both the "large" and "small labels" allows for the retrieval of corresponding sterilized package information, thereby achieving traceability.

Single-layer steam sterilization indicator label sizes: Small: 4730mm, Medium: 7750mm, Large: 97*70mm.

Traceable steam sterilization indicator label (double-layer, two-part) sizes: Small: 4745mm, Medium: 7565mm, Large: 97*85mm.

Sterilization Indicators

Sterilization indicator tapes are primarily used in conjunction with sterilization and disinfection cabinets. Medical products need to be sterilized and disinfected through different methods before they can be used.

To prevent confusion with medical products and avoid medical accidents, user units employ a large number of sterilization indicator tapes to determine whether items have been sterilized and disinfected.

-

Sterilization indicator tapes use medical crepe paper as the base material and are printed with different indicator inks. Cut an appropriate length of sterilization indicator tape, attach it to the item to be sterilized, and place it in the sterilization and disinfection cabinet.

-

After the item has completed the sterilization and disinfection process, the indicator ink on the tape will change color accordingly.

-

Observers can visually determine whether the item has been sterilized and disinfected by checking the ink color displayed on the indicator tape.

-

Record personnel can directly write down the sterilization time and other records on the indicator tape after disinfection, with the ink ensuring long-term non-fading of the text.

Ethylene oxide sterilization indicator tape

The product is made with crepe paper as the base material, coated with color-changing ink as the sterilization indicator, and backed with pressure-sensitive adhesive. It is specifically designed to be adhered to the exterior of packages containing items to be sterilized with ethylene oxide, serving as an indication of whether the package has undergone the ethylene oxide sterilization process. This prevents confusion with unsterilized packages and is suitable for quick inspection of the sterilization and disinfection process and effectiveness.

Attach the ethylene oxide sterilization indicator tape to the package containing items to be sterilized, and then place it in the ethylene oxide sterilization chamber. After sterilization with an ethylene oxide concentration of 600±50ml/L, at a temperature of 50~55℃, and a humidity of 65%~85% for more than 3 minutes, the indicator ink will change from red to green, indicating that the items have been sterilized.

We offer comprehensive technical support, including free professional labeling solutions, advice on label materials and adhesive selection, as well as online/offline assistance from professional software and hardware engineers. Service email: andy@ownlikes.cn. In pre-sales, we leverage our extensive experience in specialty labeling projects to provide clients with the most suitable hardware solutions. Additionally, all our label barcode printers and scanners come with a three-year free warranty, demonstrating our confidence in our products.

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.