Why does the adhesive label material bubble?

1. Uneven application of strong adhesive: The surface of self-adhesive label material consists of three parts: surface material, adhesive, and backing paper. The design scheme of the labeling punching machine wheel is poor, and the working pressure is insufficient.

2. Electrostatic effect: For plastic film materials, electrostatic induction can also cause bubbles on the label.

3. Improper speed adjustment and labeling method of the labeling machine: During labeling, the operating speed of the bottle body should be slightly faster than the labeling rate, which can also avoid the occurrence of bubbles.

4. Before labeling, static electricity should be completely eliminated to make the label stand upright and free from the backing paper.

5. Brushes, sponge rollers, and vacuum pumps should not be used for labeling in the labeling machine. A vulcanized rubber scraper with a certain hardness should be installed to touch the label and maintain a certain direction and amplitude of the scraper. The labeling of soft bottles requires adjusting the labeling speed, scraper amplitude, viewing angle, and spacing in between.

What are the characteristics of stickers

1. Small investment, quick results: Adhesive printed products are mostly trademarks and stickers, with small format, fast printing speed, and less production waste.

2. Flexible printing method: Adhesive stickers are not limited by printing methods, and traditional printing factories can use offset or screen printing machines for printing.

3. Multi functional: Adhesive stickers are widely used in food, cosmetics, barcode products, and can also be used as labels for special environments such as electronic and mechanical products.

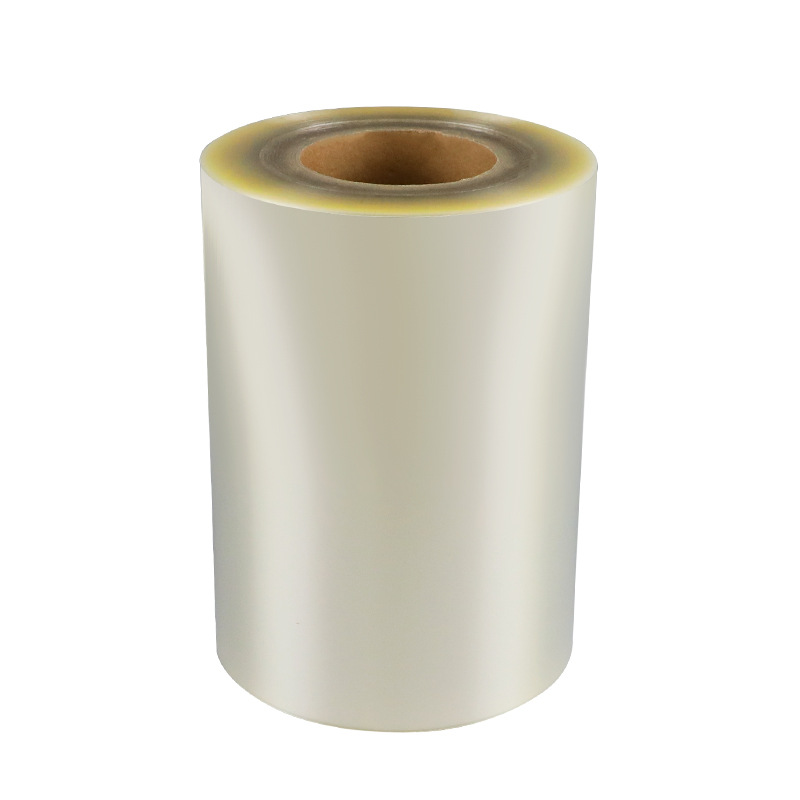

Adhesive paper structure

1. Coating: corona treatment or printing (printing treatment).

2. Face paper: According to the material, it can be divided into copperplate paper/PET/PVC, etc. The face paper and the back surface are coated with adhesive. Adhesive type: long-lasting adhesive type (strong adhesive type), detachable type (weak adhesive type), readable type.

3. Base paper: Ordinary base paper and Grassin base paper, coated with a silicon oil layer on the surface, which has a barrier effect on the adhesive.

Precautions for using adhesive anti-counterfeiting labels:

1. Before labeling, it is necessary to ensure that the object being labeled is clean, avoiding dust, water stains, oil stains, etc. After attaching the label, it should be flattened and ensure sufficient adhesion

2. The contact temperature and humidity between the label and the object to be pasted should be appropriate, and the appropriate glue and material should be selected, which varies depending on the object to be pasted

3. The label storage environment should be well ventilated, dry, moisture-proof, and maintained at a temperature of 5-30 ℃

4. Unused labels should be sealed and stored, and should be used up within 3 years as much as possible. Prevent the deterioration of glue and coating materials from affecting the effectiveness of use

5. When storing labels, do not stack them too high. Each label should be kept flat to avoid folding and prevent excessive pressure from causing glue overflow, resulting in label adhesion waste

We offer comprehensive technical support, including free professional labeling solutions, advice on label materials and adhesive selection, as well as online/offline assistance from professional software and hardware engineers. Service email: andy@ownlikes.cn. In pre-sales, we leverage our extensive experience in specialty labeling projects to provide clients with the most suitable hardware solutions. Additionally, all our label barcode printers and scanners come with a three-year free warranty, demonstrating our confidence in our products.

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.