What are the application characteristics of self-adhesive labels?

① Widely used. Not only applied in food and beverage, daily necessities, household appliances, cultural and educational supplies, but also in price tags in the field of commodity circulation, as well as in clothing, textiles, pharmaceuticals, cosmetics, and other areas.

② Easy to paste. No need for adhesives such as glue or paste, it can be peeled off and pasted immediately, which is very convenient and has no pollution to the appearance of the product.

③ Has durability. Strong adhesion, flexible adhesion, heat and moisture resistance, and resistance to aging.

④ Small investment, quick results. Adhesive printed products are mostly trademarks and stickers, with a small format. Only one trademark printing machine is needed to complete all processes such as multi-color printing, laminating, online die-cutting, automatic waste removal, hot stamping, etc. Moreover, the printing speed is fast and produces less waste. One person, one machine, less investment.

How to distinguish the quality of adhesive labels?

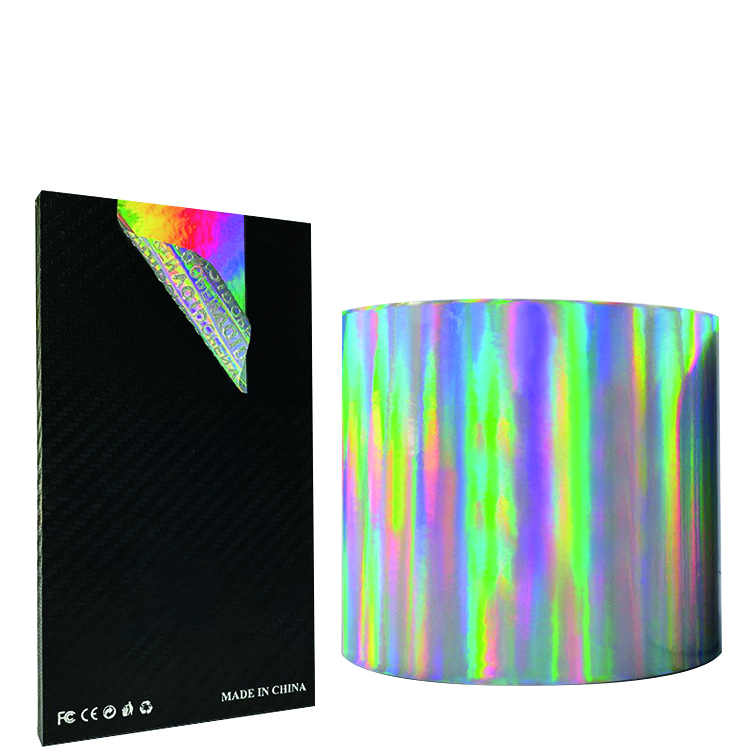

1、 Material quality. Good adhesive labels are made of high-quality materials, such as water-resistant, heat-resistant, light resistant, and wear-resistant materials, which can maintain the integrity of the label in various environments.

2、 Adhesive backing. A good self-adhesive label has a good adhesive backing that can adhere tightly to various surfaces and is not easily peeled off after long-term use.

3、 Print quality. High quality adhesive labels are printed clearly, with bright colors and sharp text patterns that can accurately convey the required information.

4、 Cutting accuracy. Cutting the edges without burrs or edges ensures the appearance of the labels is aesthetically pleasing.

5、 Durability. Adhesive labels are durable and not easily damaged or faded, and can maintain a good appearance for a long time.

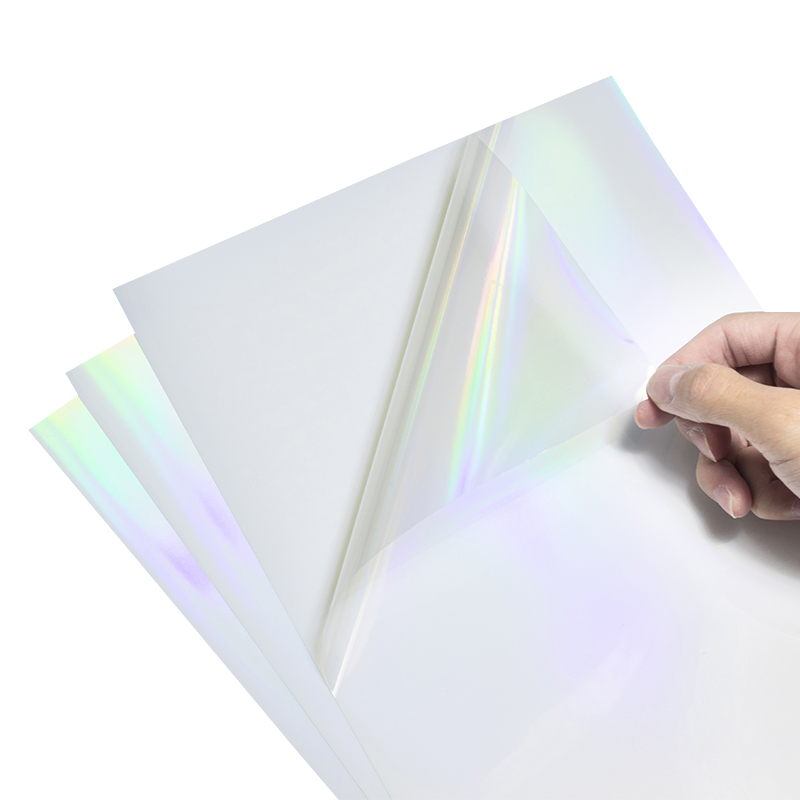

What is a self-adhesive label

Adhesive labels are composite materials made of film, paper, or special materials, with adhesive coated on the back and silicone coated paper as protective paper. They are processed through printing, die-cutting, and other techniques to create finished labels. When in use, simply peel off from the base paper and press lightly to apply it to the surface of various substrates. It can also be automatically labeled on the production line using a labeling machine.

Compared with traditional labels, self-adhesive labels do not require glue brushing, paste, or pollution, which can save labeling time and be easily and quickly applied in various situations. Various types of labels can be processed using different fabrics, adhesives, and base paper, and applied to materials that cannot be used for general paper labels. It can be said that adhesive labels are a universal label.

We offer comprehensive technical support, including free professional labeling solutions, advice on label materials and adhesive selection, as well as online/offline assistance from professional software and hardware engineers. Service email: andy@ownlikes.cn. In pre-sales, we leverage our extensive experience in specialty labeling projects to provide clients with the most suitable hardware solutions. Additionally, all our label barcode printers and scanners come with a three-year free warranty, demonstrating our confidence in our products.

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.