Adhesive label application

adhesive labels are widely used in various fields of production and life, such as:

Wood: Rubbing and printing labels. Usage: Peel off the release paper on the surface of the finished label product, align the pattern with the position to be transferred, and use nails or wooden chips to evenly rub the back of the pressure-sensitive film. Tear off the transparent film to complete the graphic and text transfer

Packaging: wheat head label, postal package, letter packaging, transportation goods labeling, envelope address label, polyester film (PET)

Electrical appliances: mobile phone internal labels, various electrical appliance labels, laptop labels, mechanical and electrical product labels, reverse pressure transfer printing labels

Products: price labels, product description labels, shelf labels, barcode labels, drug labels

Management: Book labels, vehicle inspection labels, security check labels, property labels

Office: Document and document labels, archive storage labels, various item and stationery labels

Production: Raw material labeling, processed product labeling, finished product labeling, inventory management labeling

Chemical industry: labeling of paint materials, packaging labeling of gasoline and engine oil products, labeling of various special solvent products, and polyethylene film (PE)

Jewelry: Jewelry hang tags, hang tags that are not easily attached to products

Clothing: Clothing tags, washed labels

Airport: boarding pass, luggage tag

Ticket: Train ticket, long-distance bus ticket

Metal: Transfer printing labels

Cosmetics: Screen printing has shifted towards adhesive labels and polypropylene film (PP)

Car shell: Reverse water transfer printing label (B, C transfer printing label)

Helmet surface: soluble water transfer printing label

Ceramic products: peelable film type water transfer printing label

Food industry: heat shrink film labels

Other: parking lot tickets, highway toll tickets, anti-counterfeiting labels, encrypted labels, anti-theft labels, etc

Adhesive label structure

1. Noodles. It is the carrier of adhesive label content, and the back of the face paper is coated with adhesive. There are many materials that can be used for surface materials, generally including copperplate paper, transparent polyvinyl chloride (PVC), electrostatic polyvinyl chloride (PVC), polyester (PET), laser paper, heat-resistant paper, polypropylene (PP), polycarbonate (PC), kraft paper, fluorescent paper, gold-plated paper, silver plated paper, synthetic paper, aluminum foil paper, fragile (anti-counterfeit) paper, decorative paper, fabric label (Tyvek/nylon) paper, pearlescent paper, sandwich copperplate paper, and thermal paper.

2. Film layer material. Transparent polyester (PET), semi transparent polyester (PET), transparent oriented polypropylene (OPP), semi transparent oriented polypropylene (OPP), transparent polyvinyl chloride (PVC), glossy white polyvinyl chloride (PVC), matte white polyvinyl chloride (PVC), synthetic paper, glossy gold (silver) polyester, matte gold (silver) polyester.

3. Adhesive. Universal super adhesive type, universal strong adhesive type, refrigerated food strong adhesive type, universal re release type, fiber re release type. On the one hand, it ensures moderate adhesion between the base paper and the surface paper, and on the other hand, it ensures that the surface paper can have strong adhesion with the adhesive after being peeled off.

4. Base paper material. Release paper, commonly known as "base paper", has a low surface energy and non stick surface. The base paper has a separating effect on the adhesive, so it is used as an attachment for the surface paper to ensure that the surface paper can be easily peeled off from the base paper. Commonly used are white, blue, and yellow glassine paper or onion paper, kraft paper, polyester (PET), copperplate paper, and polyethylene (PE).

What are the types of adhesive labels?

Adhesive labels can be roughly divided into two types:

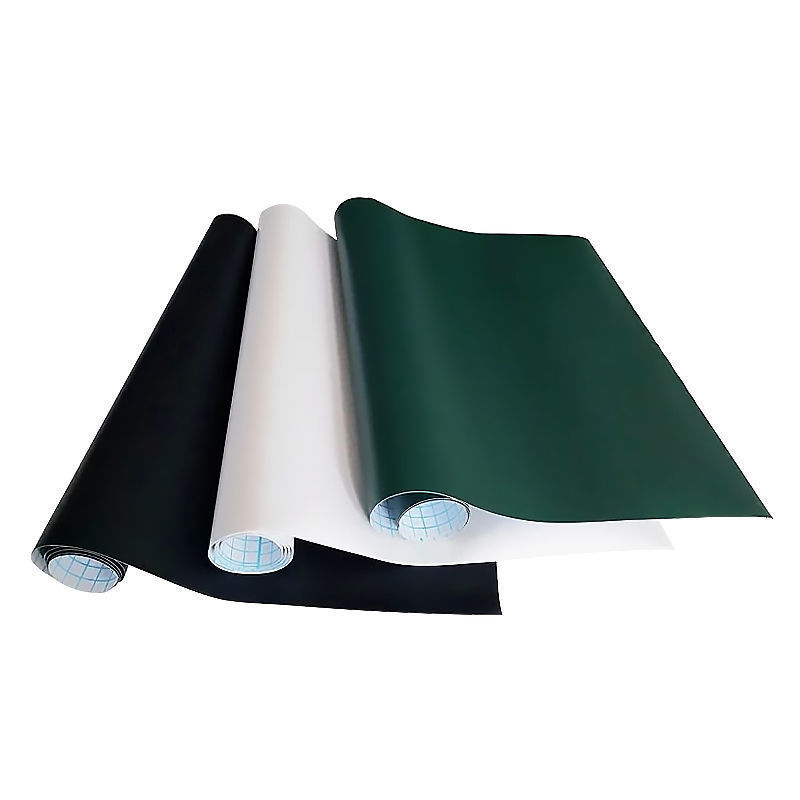

There are two types of stickers: paper stickers and film stickers

1. Paper stickers are mainly used for liquid detergent products and popular personal care products; Thin film materials are mainly used in mid to high end daily chemical products. At present, popular personal care products and household liquid cleaning products account for a large proportion in the market, so corresponding paper materials are used more

2. Thin film adhesive labels are commonly made of PE, PP, PVC, and other synthetic materials. The main types of thin film materials are white, matte, and transparent. Due to the poor printability of thin film materials, corona treatment or surface coating is generally used to enhance their printability. In order to avoid deformation or tearing of some film materials during printing and labeling processes, some materials are also subjected to directional processing, such as unidirectional or bidirectional stretching. For example, BOPP materials that have undergone bidirectional stretching are widely used for laminating writing paper, adhesive paper labels, and multi-purpose labels for information labeling and barcode printing labels. They are particularly suitable for high-speed laser printing and inkjet printing

Copperplate paper adhesive sticker is a universal label for multi-color product labeling, suitable for information labeling of drugs, food, edible oil, alcohol, beverages, electrical appliances, and cultural products

Mirror copperplate paper adhesive sticker is a high gloss sticker used for high-end multi-color product labeling, suitable for information labeling of drugs, food, edible oil, alcohol, beverages, electrical appliances, and cultural products

Aluminum foil adhesive sticker is a universal label for multi-color product labels, suitable for high-end information labels of drugs, food, and cultural products

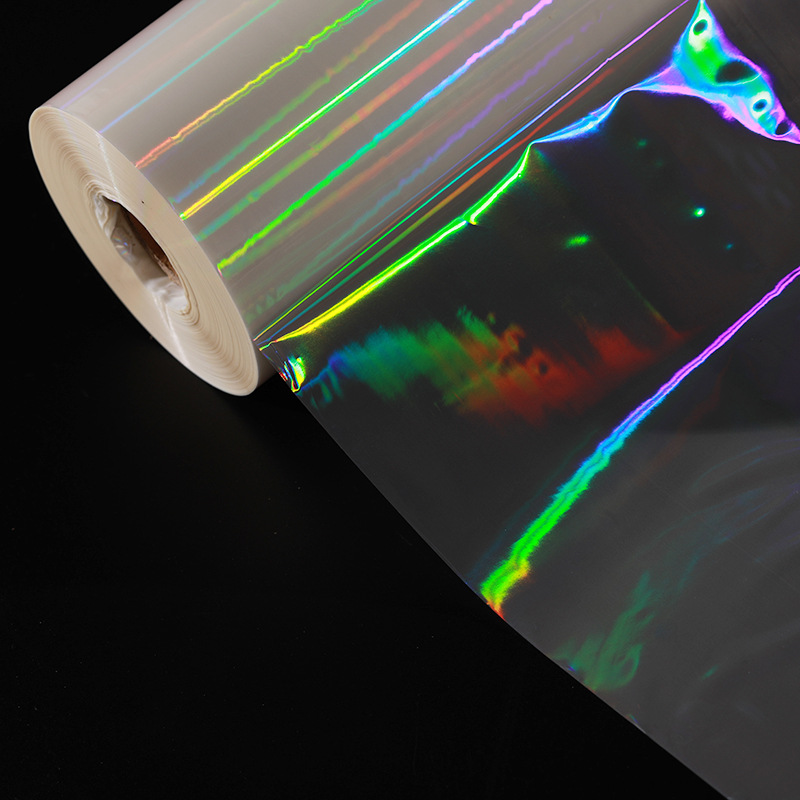

Laser film adhesive sticker is a universal sticker for multi-color product labeling, suitable for high-end information labeling of cultural products and decorations

Fragile paper adhesive labels are used for anti-counterfeiting sealing of appliances, mobile phones, drugs, food, etc. After peeling off the adhesive label, the label immediately breaks and cannot be reused

Thermal paper adhesive labels are suitable for price marking and other retail purposes

Heat transfer paper adhesive labels are suitable for printing labels on microwave ovens, weighing machines, and computer printers

Removable adhesive labels are made of materials such as copperplate paper, mirror copperplate paper, PE (polyethylene), PP (polypropylene), PET (polyester), etc., which are particularly suitable for information labels on tableware, household appliances, fruits, etc. After peeling off the adhesive label, the product leaves no traces

The washable adhesive sticker surface materials include copperplate paper, mirror copperplate paper, PE (polyethylene), PP (polypropylene), PET (polypropylene) and other materials, which are particularly suitable for beer labels, tableware, fruit and other information labels. After washing with water, the product does not leave any adhesive marks

Chemical synthetic film PE (polyethylene) adhesive label fabric has important properties such as transparent, bright milky white, matte milky white, water resistance, oil resistance, and chemical resistance. It is used for information labeling of bathroom products, cosmetics, and other extruded packaging

PP (polypropylene) adhesive label fabric has important properties such as transparent, glossy milky white, matte milky white, water resistance, oil resistance, and chemical resistance. It is used for bathroom products and cosmetics, and is suitable for information labels printed by heat transfer printing

PET (polypropylene) adhesive label fabrics include transparent, bright gold, bright silver, sub gold, sub silver, milky white, sub gloss milky white, and other important product labels with water, oil, and chemical resistance. They are used for bathroom products, cosmetics, electrical appliances, and mechanical products, and are particularly suitable for information labels on high-temperature resistant products

PVC adhesive label fabrics have important properties such as transparent, glossy milky white, matte milky white, and resistance to water, oil, and chemicals. They are used for bathroom products, cosmetics, electrical products, and are particularly suitable for information labels on high-temperature resistant products

PVC shrink film adhesive labels are suitable for battery trademark specific labels

Chemical synthetic paper is a product label with important properties such as water resistance, oil resistance, and chemical resistance, used for information labeling of high-end products and environmentally friendly products

Storage of Adhesive Labels and Analysis of Common Problems

1. Storage Requirements for Adhesive Labels:

1. Adhesive labels should be protected from direct sunlight, moisture, sun, high temperature, and ultra-low temperature

2. Adhesive labels should not be mixed with flammable or volatile hazardous materials

3. When storing self-adhesive labels, they should be sealed with moisture-proof paper or film packaging. The rolls should be stacked vertically and stored flat, and the height of each board should not exceed 1m. The goods should be at least 10cm above the ground (with wooden boards)

4. On 23+ 2 ℃ and RH65± It can be stored for one year at a relative humidity of 5%, and some adhesives can last up to two years

II. Analysis of Common Problems with Adhesive Labels:

1. The selection of permanent and removable self-adhesive label paper can be generally divided into two categories based on the performance of the adhesive: permanent adhesive and removable adhesive. (Permanence is generally applied to electronic machinery, such as electronic tags, typically for mobile phone battery tags, and removability is generally applied to food, personal care, etc., such as wet wipe tags, fruit tags, clothing labels, etc.)

2. The surface of self-adhesive label paper may be labeled on various materials such as glass, metal, cardboard, and plastic due to the use of self-adhesive materials for processing labels. Plastic can be further divided into polyvinyl chloride and high-density polyethylene. Tests have shown that different sticker surfaces have a significant impact on performance, and we must pay attention to the material of the sticker surface when choosing

3. Intuitively speaking, the surface structure of the substrate for self-adhesive label paper requires a more viscous adhesive for rough label surfaces. Conversely, a less viscous adhesive can be chosen for this purpose

4. The surface shape of the adhesive label paper substrate. The surface of the label substrate can be divided into flat and curved surfaces. If the label surface has a certain curvature (such as the surface of a medicine bottle with a diameter less than three centimeters), it may require the surface paper to have good adhesion or adhesive with strong viscosity. It is also necessary to choose materials with better flexibility and tensile strength, such as PVC. The flat surface of the object being labeled is more suitable for a wider range of labeled materials. If the surface of the object being labeled is uneven, the material selection surface will be much smaller

5. The cleanliness condition of the surface of the adhesive label paper. Adhesive materials are suitable for label substrates with clean, dry, oil-free, and dust-free surfaces. When labeling, it is necessary to keep the surface of the object being labeled dry, oil-free, and dust-free in order to achieve better labeling results. If the surface cleanliness is poor, it will relatively affect the adhesion of the adhesive label paper

We offer comprehensive technical support, including free professional labeling solutions, advice on label materials and adhesive selection, as well as online/offline assistance from professional software and hardware engineers. Service email: andy@ownlikes.cn. In pre-sales, we leverage our extensive experience in specialty labeling projects to provide clients with the most suitable hardware solutions. Additionally, all our label barcode printers and scanners come with a three-year free warranty, demonstrating our confidence in our products.

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.