Weak solvent printing adhesive material

A new type of outdoor solvent based digital inkjet printing method that is popular in the outdoor solvent based digital inkjet market, featuring high safety, low volatility, low to low toxicity, and high flash point. It uses a weak solvent ink, also known as Eco solvent ink or Light solvent ink, for inkjet printing. Weak solvent printing not only maintains the high precision advantage of water-based ink, but also overcomes the disadvantages of rough substrate and images that cannot be used outdoors caused by water-based ink

Weak solvent printing adhesive materials are materials printed with weak solvent ink. The essence of weak solvent ink is a branch of solvent based ink, and its main component is still organic solvents. Low toxicity does not mean non-toxic. Printing in a confined space can cause significant harm to human health

1. Water based printing ink uses coating ink for printing, with zero pollution and emissions in the printing environment, completely odorless, and is the only fully environmentally friendly printing material in the market

2. Water based printing film has high whiteness, good coverage, soft touch, high elasticity, stretch resistance, and good weather resistance. Weak solvent printing film, the finished product has a hard feel, low elasticity, and is prone to folding and cracking in winter weather, with poor weather resistance

The finished water-based printing film has a matte effect, which is naturally harmonious with the fabric material, comparable to silk screen effect, and high-definition and fine than direct spray effect. Weak solvent printing film finished plastic light, friction produces sound. After ironing, the clothes have a thick plastic feel, which is uncomfortable to wear

4. The unique compounding process of water-based printing film can be grafted with special processes such as drawing, flocking, silicone, hot stamping, silver stamping, thick plate, engraving film, etc., to enhance the added value of printing processing. This is not possible with other printing films

5. The water-based printing film is developed based on coating ink and can seamlessly integrate with the pure cotton direct spraying process of printing factories, replacing some white ink and white glue applications

PET adhesive material

It has high tensile strength and tear strength, excellent high temperature resistance and durability, and can be processed into highly transparent, opaque, and metalized films. The surface is coated and suitable for various types of printing and printing, with good automatic labeling ability. Due to its excellent chemical resistance and dimensional stability, it is suitable for indoor and outdoor use

PET label fabrics have important properties such as transparent, bright gold, bright silver, sub gold, sub silver, milky white, sub gloss milky white, and resistance to water, oil, and chemicals. They are used for bathroom products, cosmetics, electrical appliances, mechanical products, and are particularly suitable for information labels on high-tech products

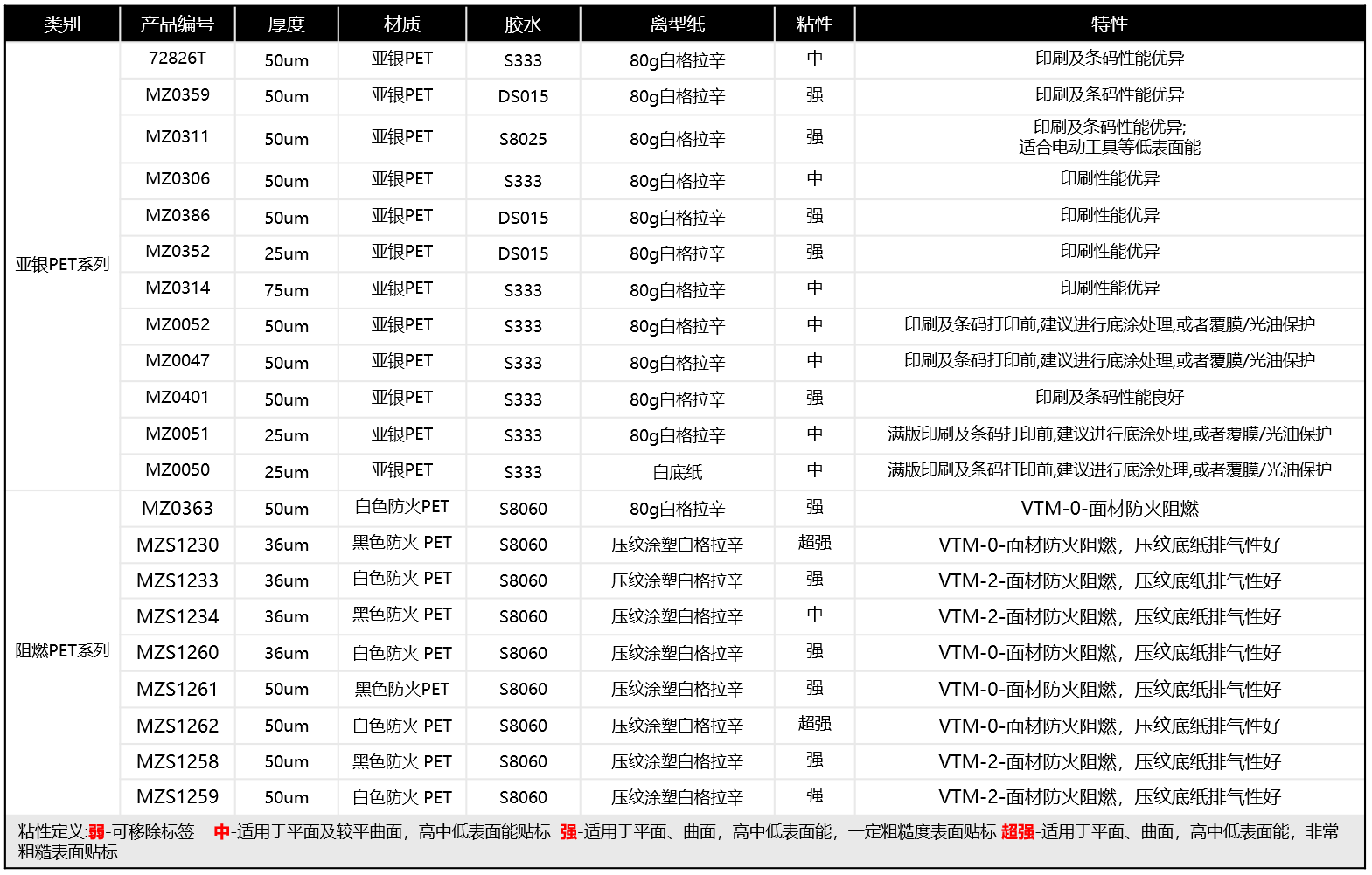

PET series adhesive material list

PE adhesive material

PE adhesive label material is an adhesive label made of polyethylene material. They have various advantages, such as water resistance, temperature resistance, scratch resistance, corrosion resistance, acid and alkali resistance, etc. Therefore, they are widely used in scenarios such as goods identification, price tags, price tags, product manuals, valuable item tags, clothing labels, etc. At the same time, when using PE adhesive labels, there is no need to apply water or oil, and they can be directly attached to the surface of objects

Advantages of PE adhesive labels:

1. Strong stickiness: The adhesive of PE self-adhesive labels has high stickiness and can quickly adhere to various material surfaces without easily falling off or shifting

2. Wide applicability: PE adhesive labels can be applied to surfaces of various materials, such as glass, metal, plastic, etc., with a very wide range of applications

3. Corrosion resistance: PE adhesive labels have good corrosion resistance and can resist the erosion of some chemicals, thereby protecting the text and patterns on the label from damage

4. Environmentally friendly and recyclable: PE materials are recyclable and will not cause pollution to the environment, while also conforming to the current trend of green and environmentally friendly development

Disadvantages of PE Adhesive Label Material:

1. Poor high temperature resistance: The high temperature resistance of PE adhesive labels is relatively poor. If they need to be used in high temperature environments, other materials of labels need to be selected

2. Limited solvent resistance: PE adhesive labels may dissolve in certain solvents, such as organic solvents, so careful selection of label materials is necessary in certain specific environments

3. Limited thickness: The thickness of PE adhesive labels is relatively thin, and if thicker labels need to be made, it may increase production costs and difficulty

List of PE Polyethylene Adhesive Materials

We offer comprehensive technical support, including free professional labeling solutions, advice on label materials and adhesive selection, as well as online/offline assistance from professional software and hardware engineers. Service email: andy@ownlikes.cn. In pre-sales, we leverage our extensive experience in specialty labeling projects to provide clients with the most suitable hardware solutions. Additionally, all our label barcode printers and scanners come with a three-year free warranty, demonstrating our confidence in our products.