High-Temperature Resistant Label Board for Printing Factory

The sticker label industry plays a crucial role in various manufacturing sectors, providing essential identification and information on products. One particular area where sticker labels are extensively utilized is in printing factories. These factories require labels that can withstand high temperatures, ensuring accurate and durable identification throughout the printing process. In this article, we will explore the significance of high-temperature resistant label boards and their applications in printing factories.

The Importance of High-Temperature Resistance

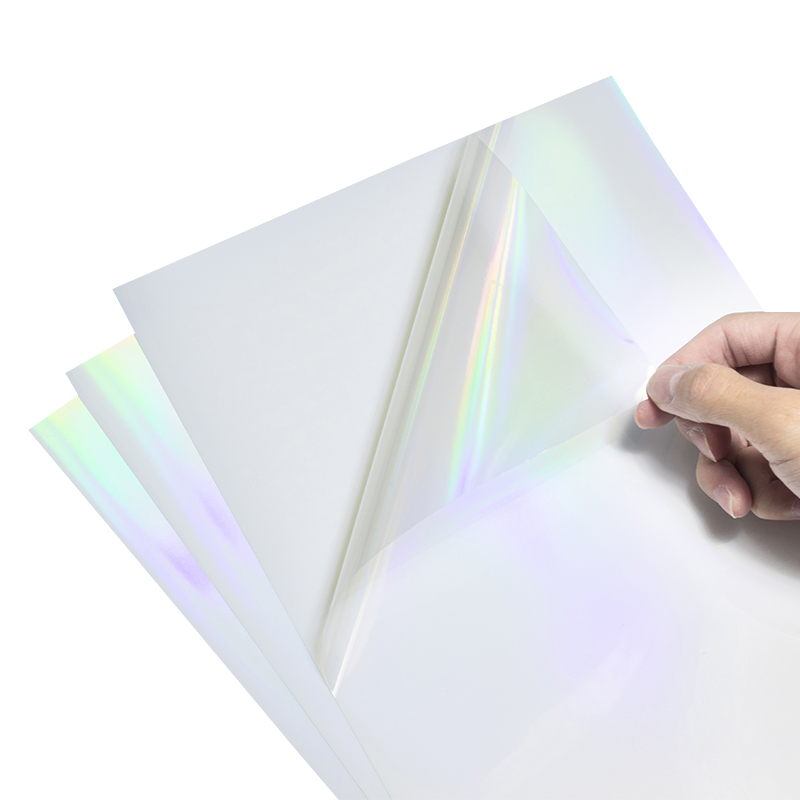

Printing factories operate under demanding conditions, with high temperatures being a common occurrence. The use of heat-intensive printing techniques, such as offset printing or heat transfer, requires labels that can endure elevated temperatures without compromising their integrity. High-temperature resistant label boards are specifically designed to withstand these extreme conditions, ensuring that the labels remain intact and legible throughout the printing process.

Traditional label boards are often unable to withstand the heat generated by printing machinery, resulting in label degradation, smudging, or even complete failure. This not only affects the visual appeal of the product but also hampers the efficiency of the printing process. High-temperature resistant label boards address these challenges, providing a reliable solution for printing factories.

Applications in Printing Factories

High-temperature resistant label boards find extensive applications in printing factories, serving various purposes during the production cycle. Let's explore some key applications:

1. Product Identification

In printing factories, product identification is of utmost importance. High-temperature resistant label boards enable clear and accurate identification of products, even in the presence of extreme heat. These labels can be affixed to various printing materials, including paper, cardboard, or plastic, ensuring that the necessary information remains intact throughout the printing process.

2. Quality Control

Printing factories need to maintain strict quality control standards to ensure the production of flawless prints. High-temperature resistant label boards play a vital role in this process by providing labels that can withstand the heat and pressure of the printing machinery. These labels can be used to mark samples, indicating the desired quality standards and facilitating easy identification during quality checks.

3. Workflow Efficiency

Efficiency is a key factor in any manufacturing process, and printing factories are no exception. High-temperature resistant label boards contribute to workflow efficiency by minimizing label failures and subsequent reprints. With these labels, printing factories can reduce downtime caused by label damage, ensuring uninterrupted production and timely delivery of printed materials.

Conclusion

High-temperature resistant label boards are an essential component in the sticker label industry, particularly for printing factories. The ability to withstand extreme temperatures ensures that these labels remain intact and legible throughout the printing process. By providing clear product identification, facilitating quality control, and improving workflow efficiency, these labels contribute significantly to the smooth functioning of printing factories. As technology continues to advance, it is crucial for the sticker label industry to adapt and develop innovative solutions to meet the evolving needs of printing factories.

We offer comprehensive technical support, including free professional labeling solutions, advice on label materials and adhesive selection, as well as online/offline assistance from professional software and hardware engineers. Service email: andy@ownlikes.cn. In pre-sales, we leverage our extensive experience in specialty labeling projects to provide clients with the most suitable hardware solutions. Additionally, all our label barcode printers and scanners come with a three-year free warranty, demonstrating our confidence in our products.

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.