Creating Indelible High-Temperature Labels

In the world of sticker label manufacturing, there is a growing demand for labels that can withstand high temperatures without compromising their legibility. Industries such as automotive, aerospace, and electronics require labels that can endure extreme heat conditions, ensuring the safety and efficiency of their products. This article explores the importance of creating indelible high-temperature labels and the challenges faced by the sticker label industry in meeting these requirements.

The Need for Indelible High-Temperature Labels

High temperatures can pose significant challenges to conventional labels, causing them to fade, smudge, or even become illegible. In industries where temperature fluctuations are common, such as automotive manufacturing, it is crucial to have labels that remain intact and readable throughout the entire product lifecycle. Indelible high-temperature labels are designed to withstand extreme heat, ensuring that critical information, such as serial numbers, barcodes, and safety warnings, remains visible and identifiable.

Challenges in Manufacturing High-Temperature Labels

Creating labels that can withstand high temperatures is not a simple task. The sticker label industry faces several challenges in meeting the requirements for indelible high-temperature labels:

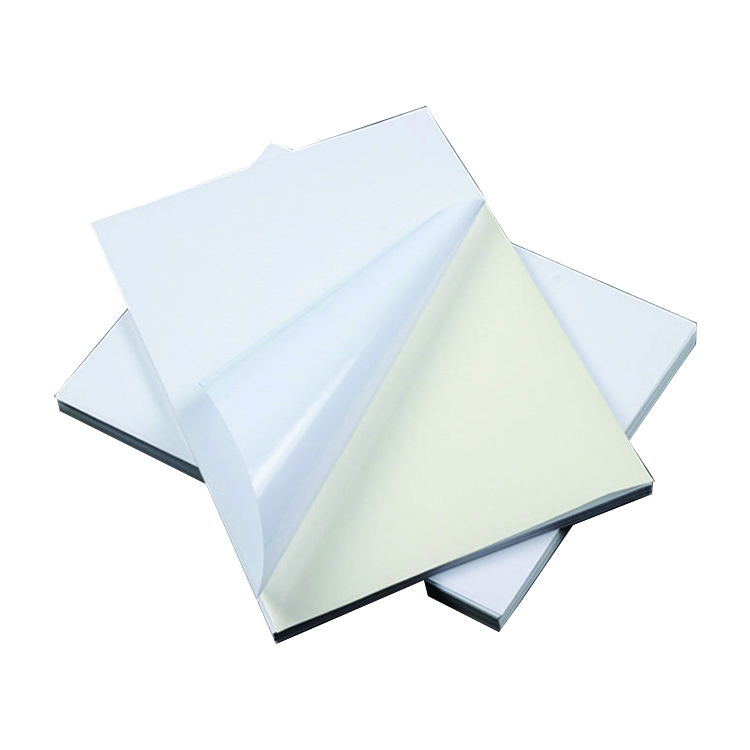

1. Material Selection: The choice of materials used in label production is crucial. Traditional paper-based labels are not suitable for high-temperature applications as they tend to degrade and lose legibility. Manufacturers must explore alternative materials, such as polyester or polyimide, which offer better resistance to heat and ensure long-lasting durability.

2. Adhesive Considerations: Adhesives used in high-temperature labels must be carefully selected to withstand extreme heat without melting or losing their bonding properties. Specialized adhesives, such as silicone-based or acrylic-based adhesives, are commonly used to ensure labels remain securely attached even in challenging environments.

3. Printing Techniques: Printing high-temperature labels requires specialized techniques to ensure the ink or toner used can withstand elevated temperatures. Thermal transfer printing, for example, utilizes heat to transfer ink onto the label surface, creating a durable and heat-resistant print. Manufacturers must invest in advanced printing technologies to achieve the desired longevity and legibility of high-temperature labels.

The Importance of Quality Assurance

Given the critical role of high-temperature labels in ensuring product safety and compliance, quality assurance is of utmost importance. Manufacturers must implement rigorous testing procedures to guarantee the performance of their labels under extreme heat conditions. These tests may include subjecting labels to various temperature cycles, exposure to chemicals, and mechanical stress to assess their resilience and durability.

Furthermore, compliance with industry standards and regulations is essential. High-temperature labels must meet specific requirements, such as UL 969 for marking and labeling systems, to ensure they adhere to safety guidelines and maintain their legibility over time.

Future Trends and Innovations

The sticker label industry is continuously evolving to meet the increasing demand for indelible high-temperature labels. Advancements in materials, adhesives, and printing technologies are driving innovation in this field. For instance, the development of nanotechnology has opened up possibilities for creating labels with enhanced heat resistance and improved durability.

Additionally, the integration of RFID (Radio Frequency Identification) technology into high-temperature labels offers new opportunities for real-time tracking and monitoring of products in extreme environments. This technology enables automated data collection and enhances supply chain management in industries where high temperatures are a concern.

Conclusion

The creation of indelible high-temperature labels is a critical aspect of the sticker label industry. These labels play a vital role in ensuring the safety, traceability, and compliance of products in industries exposed to extreme heat conditions. Manufacturers must overcome challenges related to material selection, adhesive considerations, and printing techniques to produce labels that can withstand high temperatures without compromising legibility. With continuous advancements and innovations, the future of high-temperature labels looks promising, providing industries with reliable and durable labeling solutions.

We offer comprehensive technical support, including free professional labeling solutions, advice on label materials and adhesive selection, as well as online/offline assistance from professional software and hardware engineers. Service email: andy@ownlikes.cn. In pre-sales, we leverage our extensive experience in specialty labeling projects to provide clients with the most suitable hardware solutions. Additionally, all our label barcode printers and scanners come with a three-year free warranty, demonstrating our confidence in our products.

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.