Classification of High-Temperature Labels: An Overview

Sticker labels play a crucial role in various industries, providing essential information and identification for products. However, in high-temperature environments, traditional labels may fail to withstand the extreme conditions, leading to illegible or damaged labels. To address this challenge, the development of high-temperature labels has gained significant attention. In this article, we will provide an overview of the classification of high-temperature labels, exploring their various types and applications.

1. Ceramic Labels

Ceramic labels are widely recognized for their exceptional durability and resistance to high temperatures. These labels are made from ceramic materials, such as alumina, zirconia, or silica, which exhibit excellent thermal stability. Ceramic labels can withstand temperatures up to 1000°C, making them suitable for applications in industries like aerospace, automotive, and metal processing.

2. Metal Labels

Metal labels are another popular choice for high-temperature environments. They are typically made from stainless steel or aluminum, which offer excellent resistance to heat, chemicals, and mechanical stress. Metal labels can withstand temperatures ranging from 400°C to 800°C, making them suitable for applications in the oil and gas, chemical, and manufacturing industries.

3. Polyester Labels

Polyester labels, also known as polyimide labels, are a versatile option for high-temperature applications. These labels are made from a durable polyester film that exhibits excellent thermal stability. Polyester labels can withstand temperatures up to 300°C, making them suitable for applications in electronics, automotive, and laboratory settings.

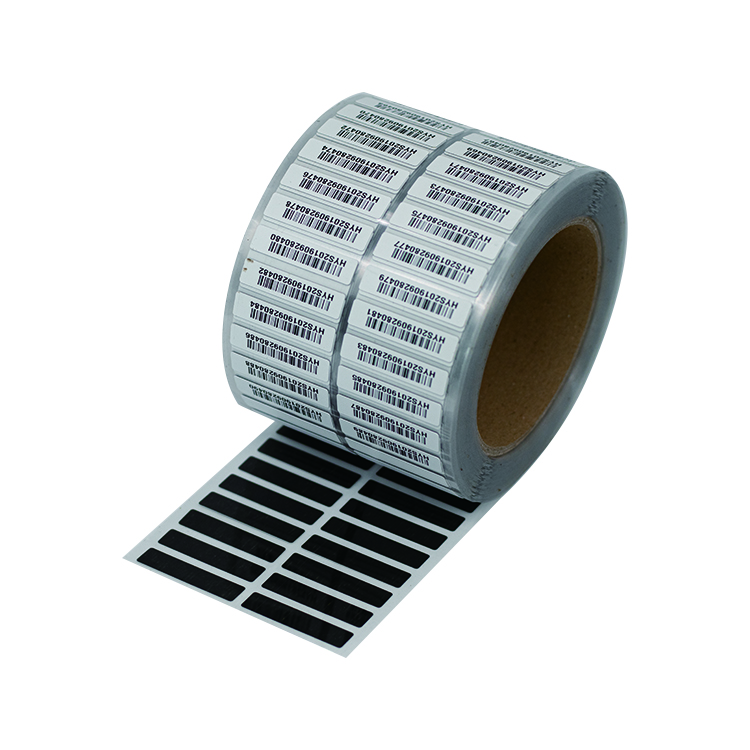

4. Thermal Transfer Labels

Thermal transfer labels are designed to withstand high temperatures through a unique printing process. These labels are made from a combination of materials, including polyester, polyimide, or ceramic, and are printed using a thermal transfer printer. The printer applies heat to transfer ink onto the label, creating a durable and heat-resistant print. Thermal transfer labels can withstand temperatures up to 600°C, making them suitable for applications in the electrical, chemical, and industrial sectors.

5. RFID Labels

RFID (Radio Frequency Identification) labels are a cutting-edge solution for high-temperature environments. These labels combine a high-temperature-resistant material, such as ceramic or polyimide, with an embedded RFID chip. RFID labels can withstand temperatures up to 200°C and provide wireless identification and tracking capabilities. They find applications in industries like manufacturing, logistics, and asset management.

Conclusion

In high-temperature environments, traditional labels may not withstand the extreme conditions, leading to illegible or damaged labels. However, with the development of high-temperature labels, industries can ensure clear and durable identification of their products. Ceramic labels, metal labels, polyester labels, thermal transfer labels, and RFID labels are all viable options for different temperature ranges and application requirements. By choosing the appropriate high-temperature label, businesses can maintain efficiency, safety, and compliance in challenging environments.

We offer comprehensive technical support, including free professional labeling solutions, advice on label materials and adhesive selection, as well as online/offline assistance from professional software and hardware engineers. Service email: andy@ownlikes.cn. In pre-sales, we leverage our extensive experience in specialty labeling projects to provide clients with the most suitable hardware solutions. Additionally, all our label barcode printers and scanners come with a three-year free warranty, demonstrating our confidence in our products.

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.