High-Temperature Labeling Standards for Laboratories

In laboratory environments, accurate and reliable labeling is crucial for the safe and efficient management of various materials and equipment. High-temperature labeling plays a significant role in ensuring that labels remain intact and readable even under extreme conditions. This article explores the importance of high-temperature labeling standards in the sticker label industry and highlights the key considerations for creating durable and professional labels.

1. Understanding High-Temperature Labeling

High-temperature labeling refers to the process of creating labels that can withstand elevated temperatures without compromising their adhesive strength, print quality, or readability. In laboratory settings, where extreme heat may be present due to autoclaving, sterilization, or other high-temperature processes, standard labels are often insufficient and can become illegible or detach from surfaces.

To address these challenges, high-temperature labels are specifically designed to withstand a range of temperatures, typically up to 300°C or higher. These labels are made from durable materials and utilize advanced adhesives that can resist heat, chemicals, and other harsh conditions commonly encountered in laboratories.

2. Importance of High-Temperature Labeling Standards

Accurate and reliable labeling is essential for maintaining the integrity of samples, chemicals, and equipment in laboratories. High-temperature labeling standards ensure that labels remain affixed and readable, providing critical information such as item identification, expiration dates, safety warnings, and handling instructions.

By adhering to high-temperature labeling standards, laboratories can:

- Enhance safety: Labels that remain intact and legible even under extreme heat conditions help prevent accidents and minimize the risk of mishandling hazardous materials.

- Improve efficiency: Clearly labeled equipment and samples enable easy identification, reducing the time spent searching for specific items and streamlining laboratory workflows.

- Ensure compliance: High-temperature labeling standards help laboratories meet regulatory requirements and maintain proper documentation, which is particularly important in industries such as healthcare, pharmaceuticals, and research.

3. Key Considerations for High-Temperature Labels

Creating effective high-temperature labels requires careful consideration of various factors. Here are some key considerations:

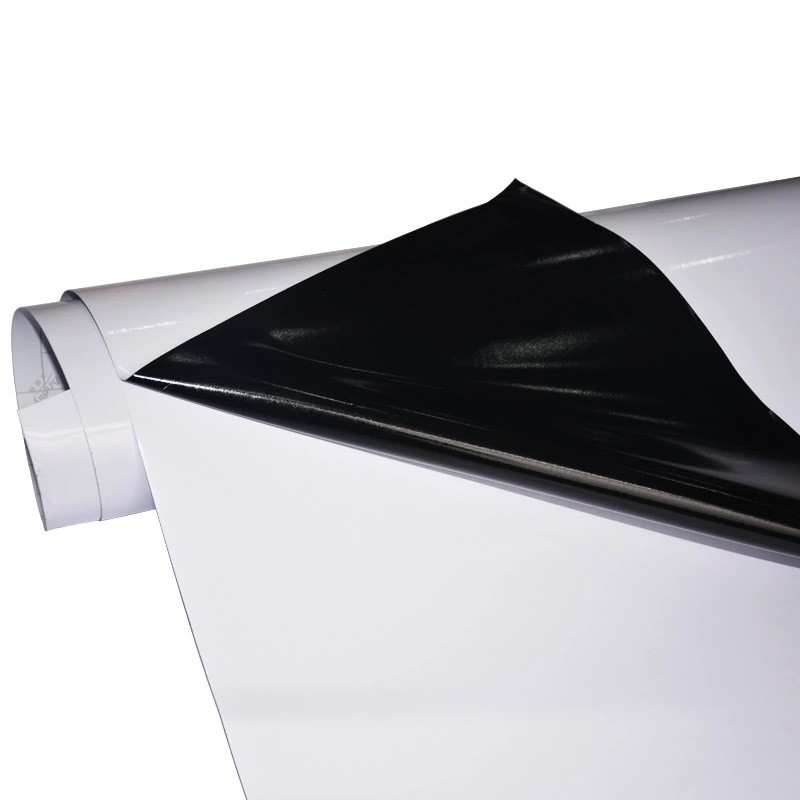

Material selection: Choose label materials that can withstand high temperatures without warping, fading, or losing adhesion. Common options include polyester, polyimide, and ceramic labels, which offer excellent resistance to heat, chemicals, and abrasion.

Adhesive properties: Opt for adhesives that can withstand high temperatures and maintain their bonding strength. High-performance adhesives, such as silicone-based or acrylic adhesives, are commonly used for high-temperature labeling.

Print quality: Ensure that labels are printed with high-quality, durable inks that can withstand extreme heat without smudging or fading. Thermal transfer printing or laser etching are popular methods for creating long-lasting labels.

Label design: Consider the size, shape, and layout of the labels to ensure they fit properly on different surfaces and can accommodate all necessary information. Utilize clear and concise fonts, appropriate colors, and standardized symbols for improved readability.

Testing and validation: Before implementing high-temperature labels, conduct thorough testing to ensure they meet the desired performance requirements. Subject labels to simulated high-temperature conditions and evaluate their durability, legibility, and adhesive strength.

Conclusion

High-temperature labeling standards are crucial for laboratories to maintain safety, efficiency, and compliance. By utilizing durable materials, advanced adhesives, and proper label design, laboratories can ensure that labels remain intact and readable even under extreme heat. Implementing high-temperature labeling standards not only enhances the overall management of materials and equipment but also contributes to a safer and more productive laboratory environment.

We offer comprehensive technical support, including free professional labeling solutions, advice on label materials and adhesive selection, as well as online/offline assistance from professional software and hardware engineers. Service email: andy@ownlikes.cn. In pre-sales, we leverage our extensive experience in specialty labeling projects to provide clients with the most suitable hardware solutions. Additionally, all our label barcode printers and scanners come with a three-year free warranty, demonstrating our confidence in our products.

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.