High-Temperature Resistant Labels for Printed Circuits

Sticker labels play a crucial role in various industries, providing essential information and identification for products. In the electronics industry, where printed circuits are prevalent, the demand for high-temperature resistant labels has been steadily increasing. These labels are specifically designed to withstand elevated temperatures, ensuring durability and legibility in challenging environments. In this article, we will explore the significance of high-temperature resistant labels for printed circuits and their applications.

The Importance of High-Temperature Resistance

Printed circuits are widely used in electronic devices, ranging from consumer electronics to aerospace and automotive applications. These circuits consist of intricate patterns of conductive materials that enable the flow of electrical signals. During the manufacturing process, these circuits often undergo high-temperature operations, such as soldering and reflow processes, which subject the labels to extreme heat.

Conventional labels are not designed to withstand these elevated temperatures, making them prone to degradation, smudging, or complete failure. High-temperature resistant labels, on the other hand, are specifically engineered to endure these harsh conditions, ensuring that the critical information they carry remains intact and legible throughout the circuit's lifecycle.

Applications of High-Temperature Resistant Labels

1. Circuit Board Identification:

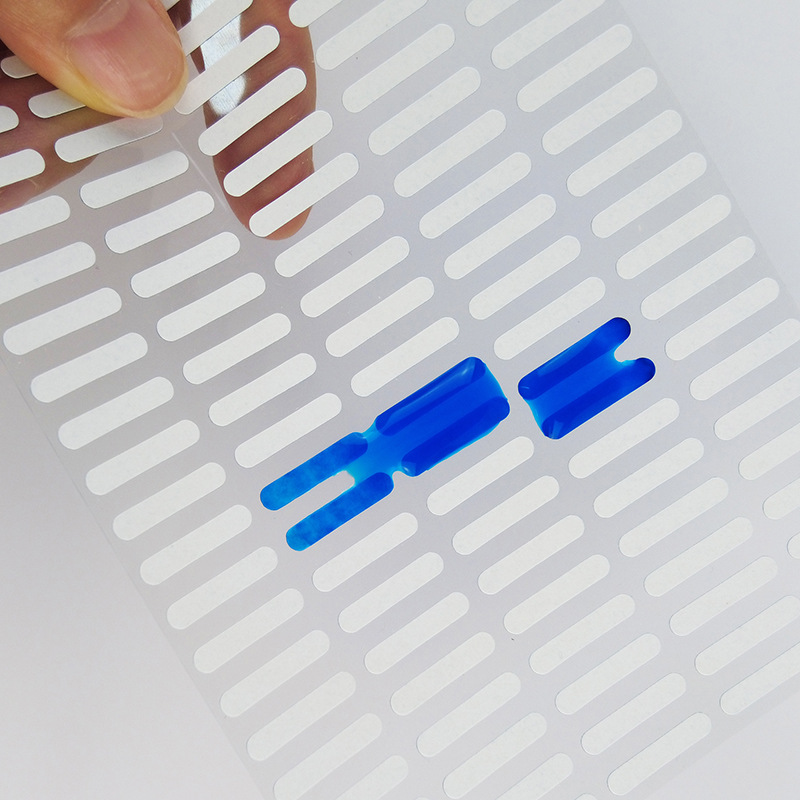

High-temperature resistant labels are commonly used to identify different components and sections on printed circuit boards (PCBs). These labels are applied directly onto the PCBs, providing clear information about the circuit's functionality, manufacturing date, serial numbers, and other essential details. The ability to withstand high temperatures ensures that the labels remain affixed and readable during the PCB assembly process.

2. Traceability and Quality Control:

In the electronics industry, traceability and quality control are of utmost importance. High-temperature resistant labels enable manufacturers to track and identify individual circuits throughout the production and testing processes. These labels can withstand the heat generated during testing and ensure that crucial information, such as batch numbers and quality control indicators, remains intact.

3. Component Labeling:

Electronic devices consist of numerous components, each requiring precise identification. High-temperature resistant labels are used to mark individual components, such as resistors, capacitors, and integrated circuits. These labels provide essential information, including part numbers, specifications, and manufacturing details. By withstanding high temperatures, these labels ensure that the information remains legible even after soldering or reflow processes.

Key Features of High-Temperature Resistant Labels

1. Temperature Resistance:

High-temperature resistant labels are designed to withstand extreme temperatures typically encountered during soldering and reflow processes. They can endure temperatures ranging from 200°C to 300°C without compromising their adhesion or readability.

2. Chemical Resistance:

Labels used in the electronics industry must also withstand exposure to various chemicals, such as fluxes and cleaning agents. High-temperature resistant labels are engineered to resist these chemicals, ensuring that the printed information remains intact and legible.

3. Durability:

High-temperature resistant labels are manufactured using robust materials that offer excellent durability. They are resistant to abrasion, moisture, and other environmental factors, ensuring that the labels remain intact and readable throughout the circuit's lifecycle.

Conclusion

In the electronics industry, where printed circuits are extensively used, high-temperature resistant labels play a vital role in providing essential information and identification. These labels are designed to withstand extreme temperatures, ensuring durability and legibility during the manufacturing, assembly, and testing processes. With their ability to endure high temperatures, resist chemicals, and maintain their integrity, high-temperature resistant labels contribute significantly to the reliability and traceability of printed circuits.

For manufacturers and end-users alike, investing in high-quality high-temperature resistant labels is essential to ensure the longevity and functionality of electronic devices. By choosing labels that meet the specific requirements of the industry, manufacturers can enhance their production processes and provide reliable products to their customers.

We offer comprehensive technical support, including free professional labeling solutions, advice on label materials and adhesive selection, as well as online/offline assistance from professional software and hardware engineers. Service email: andy@ownlikes.cn. In pre-sales, we leverage our extensive experience in specialty labeling projects to provide clients with the most suitable hardware solutions. Additionally, all our label barcode printers and scanners come with a three-year free warranty, demonstrating our confidence in our products.

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.