Customize High-Temperature Resistant Labels

Sticker labels play a crucial role in various industries, providing essential information and identification for products. However, in certain environments where high temperatures are present, standard labels might fail to withstand the extreme conditions. To address this challenge, the sticker label industry has introduced high-temperature resistant labels, which are designed to withstand elevated temperatures without compromising their functionality. In this article, we will explore the importance of these labels and how they are customized to meet the specific needs of different industries.

The Significance of High-Temperature Resistant Labels

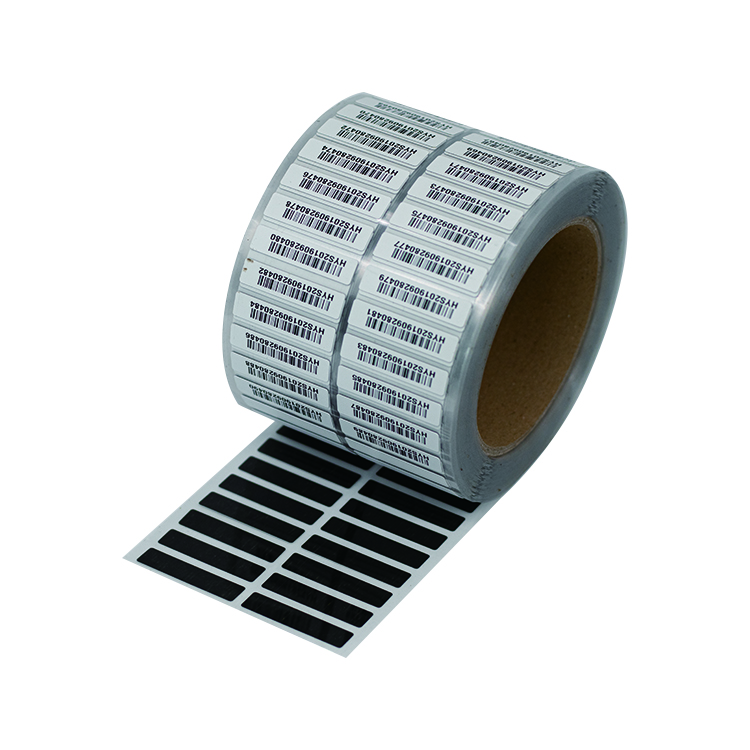

High-temperature resistant labels are essential for industries where products are exposed to extreme heat or thermal processes. These labels are commonly used in automotive, aerospace, electronics, and industrial manufacturing sectors, among others. The ability of these labels to withstand high temperatures ensures that crucial information, such as barcodes, serial numbers, and safety warnings, remains readable and intact throughout the product's lifecycle.

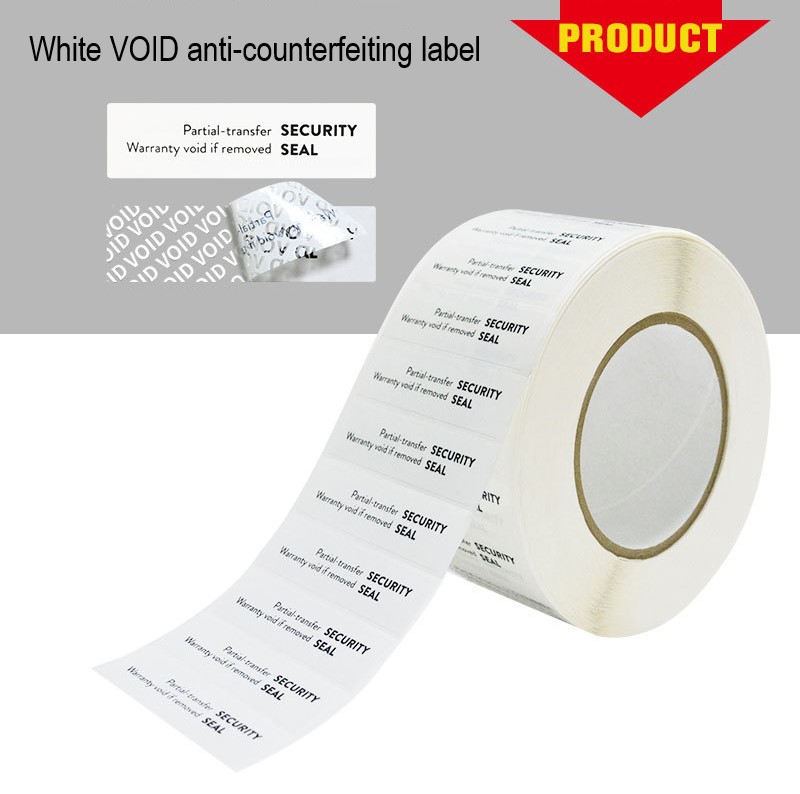

One of the primary concerns in industries that require high-temperature resistant labels is the potential for label degradation or failure under extreme conditions. Standard labels may lose their adhesive properties, fade, or become illegible when exposed to high temperatures. This can lead to significant safety risks, loss of traceability, and decreased efficiency in the production process. High-temperature resistant labels address these concerns by offering durability, legibility, and reliable adhesion even in extreme heat environments.

Customization for Specific Industries

High-temperature resistant labels are not one-size-fits-all solutions. They are customized to meet the specific requirements of different industries. Let's explore some key aspects of customization:

Material Selection

The choice of materials is crucial in designing high-temperature resistant labels. Common materials used include polyester, polyimide, and ceramic coatings. Polyester labels are suitable for applications requiring resistance to temperatures up to 300°C, while polyimide labels can withstand even higher temperatures, up to 500°C. Ceramic coatings are often used for extreme applications, such as in the aerospace industry, where labels need to endure temperatures exceeding 1000°C. The selection of the appropriate material ensures that the label remains intact and readable throughout the product's lifespan.

Adhesive Properties

The adhesive used in high-temperature resistant labels is formulated to withstand extreme heat without losing its bonding strength. The adhesive must maintain its integrity even when exposed to prolonged heat, chemicals, or other harsh conditions. Customizing the adhesive properties ensures that the label remains securely attached to the product, preventing any potential safety risks or loss of information.

Print Quality and Legibility

The printing process for high-temperature resistant labels must ensure excellent print quality and legibility. Specialized printing techniques, such as thermal transfer printing or laser etching, are commonly used to achieve high-resolution and durable prints. These techniques ensure that the labels remain readable, even after prolonged exposure to high temperatures, ensuring accurate tracking, identification, and safety compliance.

Compliance with Industry Standards

Customized high-temperature resistant labels must comply with industry-specific standards and regulations. Industries such as automotive and aerospace have stringent requirements for labels, including resistance to high temperatures, chemicals, and UV exposure. Customization ensures that the labels meet these standards, providing reliability and compliance in demanding environments.

Conclusion

Customize high-temperature resistant labels are essential for industries where extreme heat is a constant factor. These labels provide durability, legibility, and reliable adhesion, ensuring that crucial information remains intact throughout the product's lifecycle. By carefully selecting materials, adhesive properties, and printing techniques, these labels can be customized to meet the specific needs of different industries. Compliance with industry standards further guarantees the reliability and functionality of these labels. With customized high-temperature resistant labels, industries can maintain safety, traceability, and efficiency even in the harshest environments.

We offer comprehensive technical support, including free professional labeling solutions, advice on label materials and adhesive selection, as well as online/offline assistance from professional software and hardware engineers. Service email: andy@ownlikes.cn. In pre-sales, we leverage our extensive experience in specialty labeling projects to provide clients with the most suitable hardware solutions. Additionally, all our label barcode printers and scanners come with a three-year free warranty, demonstrating our confidence in our products.

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.