High-Temperature Label Tape Manufacturer: Customizable Solutions for Extreme Heat Environments

When it comes to labeling products in extreme heat environments, durability and reliability are of utmost importance. Industries such as automotive, aerospace, electronics, and manufacturing often face the challenge of finding suitable label solutions that can withstand high temperatures without compromising their functionality. This is where high-temperature label tape manufacturers play a crucial role in providing customizable solutions that meet the unique demands of these industries.

The Importance of High-Temperature Label Tape

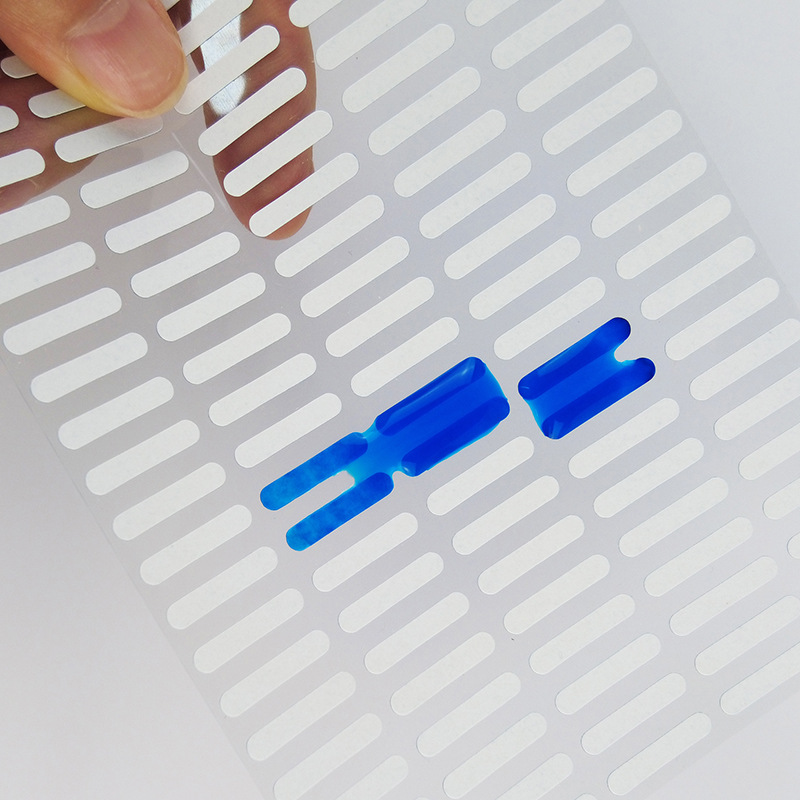

In extreme heat environments, regular labels may fail to adhere properly, fade, or even melt, rendering them ineffective. High-temperature label tape, on the other hand, is specifically designed to withstand elevated temperatures, ensuring that critical information remains visible and intact. These labels are commonly used for applications such as asset tracking, product identification, warning labels, and barcoding.

High-temperature label tape manufacturers understand the challenges faced by industries operating in extreme heat environments. They employ advanced materials and adhesive technologies to create labels that can withstand temperatures ranging from 250°F to 600°F (121°C to 316°C) or even higher, depending on the specific requirements.

Customizable Solutions for Every Need

High-temperature label tape manufacturers offer a wide range of customizable solutions to meet the diverse needs of different industries. These solutions include:

1. Material Selection:

Manufacturers provide a variety of label materials suitable for high-temperature applications. These materials may include polyester, polyimide, ceramic, or aluminum, each with its own unique properties and temperature resistance capabilities. By selecting the most appropriate material, industries can ensure that their labels remain intact and legible even in extreme heat conditions.

2. Adhesive Options:

The adhesive used in high-temperature label tape is specially formulated to withstand extreme heat without losing its bonding strength. Manufacturers offer different adhesive options, such as silicone-based or acrylic-based adhesives, allowing industries to choose the one that best suits their specific requirements.

3. Custom Printing:

High-temperature label tape manufacturers understand that each industry has its own unique labeling needs. They offer custom printing services, allowing businesses to incorporate their logos, barcodes, serial numbers, and other essential information onto the labels. This ensures that the labels not only withstand high temperatures but also meet specific branding and identification requirements.

4. Resistance to Chemicals and Solvents:

In addition to extreme heat, many industries also face exposure to chemicals and solvents. High-temperature label tape manufacturers provide solutions that are resistant to these substances, ensuring that the labels remain intact and readable even in harsh chemical environments.

Applications and Benefits

The application of high-temperature label tape extends to various industries, including:

1. Automotive:

In the automotive industry, high-temperature labels are used for engine components, exhaust systems, and other parts that are exposed to extreme heat. These labels ensure that vital information, such as manufacturing dates, part numbers, and safety warnings, remains visible throughout the lifespan of the vehicle.

2. Aerospace:

Aerospace manufacturers rely on high-temperature label tape for labeling critical components, such as engines, turbines, and fuselage parts. These labels help track maintenance schedules, provide safety instructions, and ensure compliance with industry regulations.

3. Electronics:

Electronic devices often generate significant heat during operation. High-temperature label tape is used to label circuit boards, power supplies, and other electronic components. These labels withstand the heat generated by the devices, ensuring that important information, such as serial numbers and safety warnings, remains legible.

4. Manufacturing:

In the manufacturing industry, high-temperature label tape is used for labeling machinery, tools, and equipment that operate in extreme heat environments. These labels help track inventory, provide usage instructions, and improve overall safety in the workplace.

The benefits of using high-temperature label tape include:

- Durability: These labels are designed to withstand extreme heat, ensuring they remain intact and readable for extended periods. - Legibility: High-temperature label tape maintains its visibility, allowing critical information to be easily read and understood. - Compliance: Industries must adhere to safety regulations and standards. High-temperature labels help meet these requirements by providing clear warnings and instructions. - Efficiency: Customizable solutions enable businesses to streamline their labeling processes and improve overall efficiency in high-temperature environments.Conclusion

High-temperature label tape manufacturers play a vital role in providing customizable solutions for industries operating in extreme heat environments. Their expertise in material selection, adhesive options, custom printing, and resistance to chemicals ensures that labels remain intact and legible even under the harshest conditions. By utilizing high-temperature label tape, industries can enhance safety, improve efficiency, and maintain compliance with industry standards.

We offer comprehensive technical support, including free professional labeling solutions, advice on label materials and adhesive selection, as well as online/offline assistance from professional software and hardware engineers. Service email: andy@ownlikes.cn. In pre-sales, we leverage our extensive experience in specialty labeling projects to provide clients with the most suitable hardware solutions. Additionally, all our label barcode printers and scanners come with a three-year free warranty, demonstrating our confidence in our products.

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.