High-Temperature Resistant Label Materials in Fuyang

The sticker label industry plays a crucial role in various sectors, providing essential product information, branding, and identification. As industries continue to evolve, there is an increasing demand for label materials that can withstand high temperatures. Fuyang, a renowned hub for label production, has emerged as a leader in manufacturing high-temperature resistant label materials. In this article, we will explore the significance of these materials and their applications in different industries.

Understanding High-Temperature Resistant Label Materials

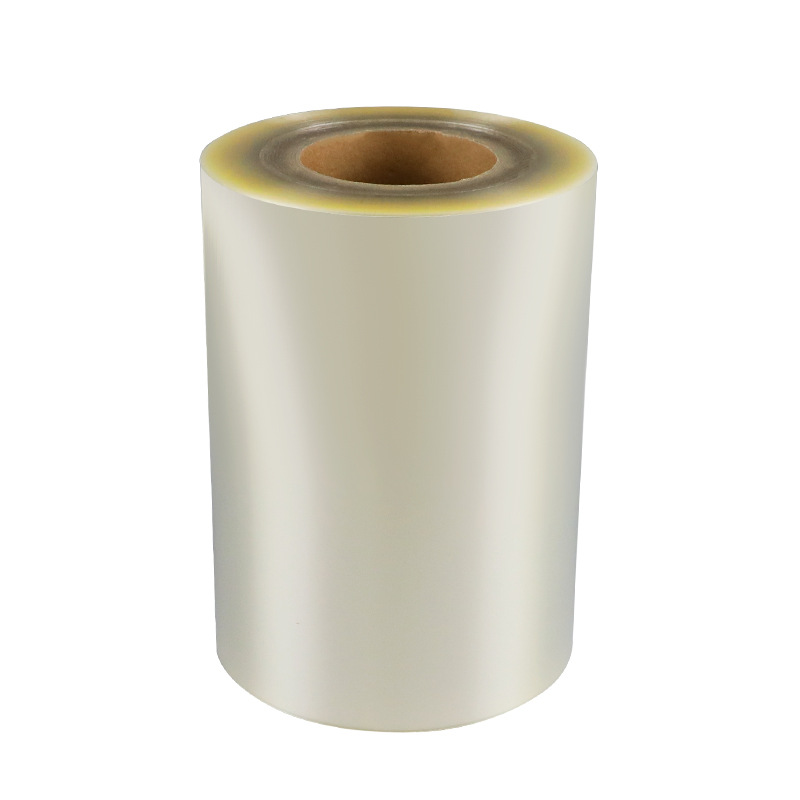

High-temperature resistant label materials are specifically designed to withstand extreme heat conditions without compromising their adhesive properties or legibility. These materials are engineered using advanced technologies and specialized components, ensuring durability and reliability in harsh environments.

One of the key components used in high-temperature resistant label materials is a robust adhesive. This adhesive is formulated to maintain its bonding strength even when exposed to temperatures exceeding 300 degrees Celsius. Additionally, the facestock used in these materials is carefully selected to withstand heat, preventing any distortion or discoloration.

Applications in the Automotive Industry

The automotive industry heavily relies on high-temperature resistant label materials due to the extreme heat generated by engines and exhaust systems. These labels are used for various purposes, including part identification, warning labels, and branding. With their ability to withstand high temperatures, these labels ensure important information remains intact and visible throughout the lifespan of the vehicle.

In the automotive manufacturing process, high-temperature resistant labels are applied to critical components such as engine parts, exhaust systems, and brake components. These labels play a vital role in ensuring accurate identification and traceability, even in extreme conditions. Moreover, they contribute to the overall safety and reliability of the vehicles.

Utilization in the Electronics Industry

The electronics industry is another sector that greatly benefits from high-temperature resistant label materials. With the constant miniaturization and increased power densities of electronic devices, the ability to withstand high temperatures is crucial for labels used in this industry.

High-temperature resistant labels find applications in electronic components, circuit boards, and other devices that are exposed to elevated temperatures during manufacturing processes or in operation. These labels ensure clear identification, tracking, and compliance with safety standards, even in high-temperature environments.

Advancements in Material Technology

Continuous research and development efforts have led to significant advancements in high-temperature resistant label materials. Manufacturers in Fuyang have been at the forefront of these innovations, constantly improving the performance and durability of these labels.

New materials, such as ceramic-based facestocks and high-performance adhesives, have been introduced to enhance the heat resistance of labels. These materials exhibit exceptional stability and can withstand extreme temperatures, making them ideal for demanding applications in industries such as aerospace, defense, and energy.

Conclusion

High-temperature resistant label materials have become indispensable in industries where extreme heat conditions are prevalent. Fuyang's expertise in manufacturing these materials has positioned it as a leading supplier in the global market. With the continuous advancements in material technology, high-temperature resistant labels will continue to play a vital role in ensuring product identification, safety, and compliance in various industries.

Disclaimer: The views and opinions expressed in this article are solely those of the author and do not necessarily reflect the official policy or position of any agency or organization.

We offer comprehensive technical support, including free professional labeling solutions, advice on label materials and adhesive selection, as well as online/offline assistance from professional software and hardware engineers. Service email: andy@ownlikes.cn. In pre-sales, we leverage our extensive experience in specialty labeling projects to provide clients with the most suitable hardware solutions. Additionally, all our label barcode printers and scanners come with a three-year free warranty, demonstrating our confidence in our products.

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.