How to Choose High-Temperature Resistant Label Materials?

High-temperature resistant label materials play a crucial role in various industries where labels are exposed to extreme heat and harsh environments. These labels need to withstand high temperatures without compromising their functionality or appearance. In this article, we will explore the key factors to consider when choosing high-temperature resistant label materials.

1. Temperature Range

The first and most important factor to consider is the temperature range that the label will be exposed to. Different applications require different temperature resistance levels. Determine the maximum and minimum temperatures the label will encounter during its lifespan. This will help you select a label material that can withstand those specific temperature extremes.

2. Material Composition

The material composition of the label is crucial for high-temperature resistance. Look for materials that are specifically designed to withstand heat, such as polyester, polyimide, or ceramic-filled materials. These materials have excellent thermal stability and can resist deformation or degradation at high temperatures.

3. Adhesive Properties

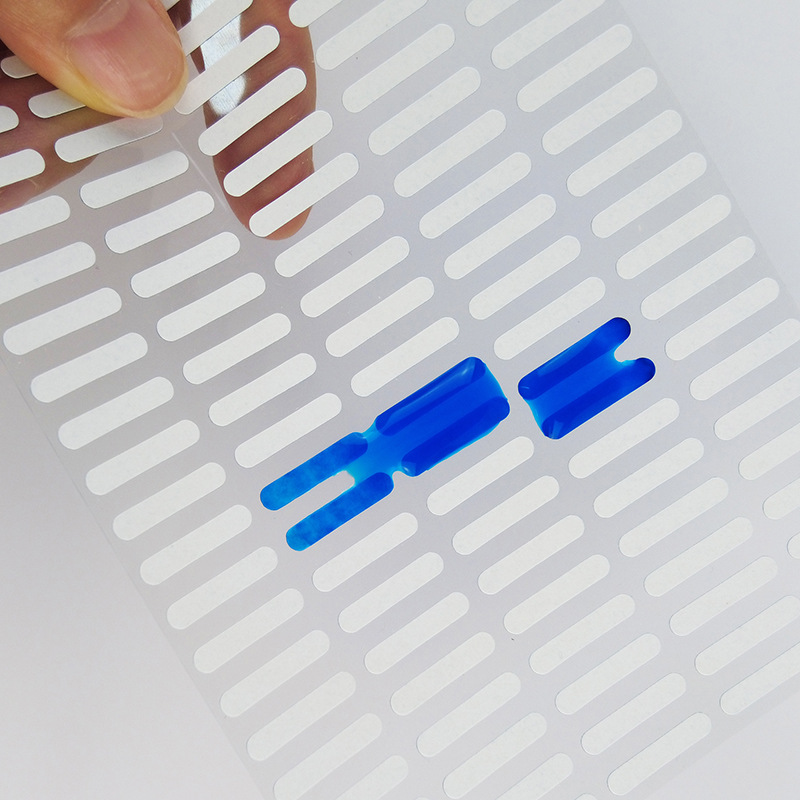

The adhesive used on the label should also be able to withstand high temperatures. Consider adhesives that are specifically formulated for high-temperature applications. Silicone-based adhesives are often preferred for their ability to maintain adhesion even at elevated temperatures. Ensure that the adhesive can bond effectively to the surface where the label will be applied.

4. Durability and Resistance

Labels exposed to high temperatures often face additional challenges like chemical exposure, abrasion, or moisture. Choose label materials that are resistant to these factors. Look for labels with chemical-resistant coatings or laminates to protect the print and ensure longevity. Additionally, consider labels with UV resistance if they will be exposed to sunlight.

5. Compliance Requirements

Depending on the industry or application, there may be specific compliance requirements for labels. Ensure that the chosen label materials meet the necessary standards and regulations. For example, labels used in the automotive industry may need to comply with automotive specifications, while labels used in the food industry may require FDA approval.

6. Testing and Sample Evaluation

Before finalizing your choice, it is advisable to conduct testing and sample evaluations. Test the label materials under the expected temperature conditions to ensure they perform as expected. Evaluate the label's adhesion, readability, and overall durability. This step will help you identify any potential issues and make an informed decision.

Conclusion

Choosing the right high-temperature resistant label materials is crucial for ensuring the longevity and functionality of labels in extreme heat environments. Consider the temperature range, material composition, adhesive properties, durability, compliance requirements, and conduct thorough testing before making a final decision. By selecting the appropriate label materials, you can ensure that your labels remain intact and readable even in the most challenging conditions.

We offer comprehensive technical support, including free professional labeling solutions, advice on label materials and adhesive selection, as well as online/offline assistance from professional software and hardware engineers. Service email: andy@ownlikes.cn. In pre-sales, we leverage our extensive experience in specialty labeling projects to provide clients with the most suitable hardware solutions. Additionally, all our label barcode printers and scanners come with a three-year free warranty, demonstrating our confidence in our products.

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.