High-Temperature Resistant Identification Labels for the Electronics Industry

In the fast-paced and ever-evolving electronics industry, efficient and accurate identification of components and products is crucial for seamless operations. High-temperature resistant identification labels play a vital role in this domain, ensuring that critical information remains intact even under extreme heat conditions. In this article, we will explore the significance of these labels and their various applications in the electronics industry.

The Importance of High-Temperature Resistant Identification Labels

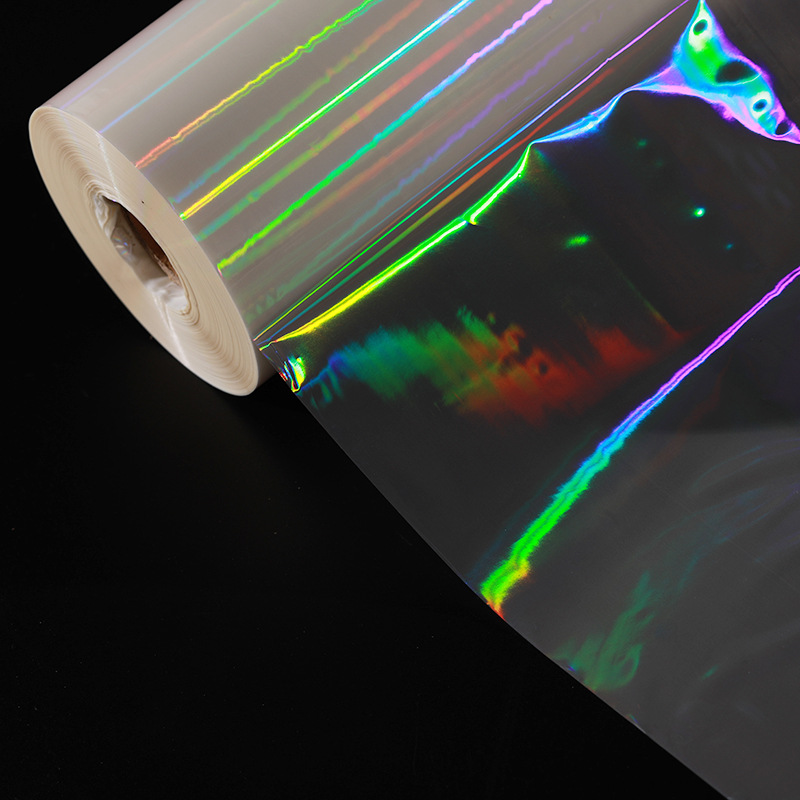

High-temperature resistant identification labels are specifically designed to withstand extreme temperatures, making them ideal for the demanding environments encountered in the electronics industry. These labels are made from durable materials that can endure high heat without compromising their adhesive properties or legibility. By using these labels, manufacturers can ensure that crucial information such as product codes, serial numbers, and barcodes remain intact throughout the manufacturing, assembly, and usage processes.

One of the primary benefits of high-temperature resistant identification labels is their ability to withstand the soldering process. During the manufacturing of electronic components, soldering is a common technique used to join parts together. The high temperatures involved in this process can damage regular labels, rendering them unreadable. However, high-temperature resistant labels can withstand the heat, ensuring that the identification information remains visible and traceable.

Applications of High-Temperature Resistant Identification Labels

High-temperature resistant identification labels find extensive applications in the electronics industry. Let's explore some of the key areas where these labels are utilized:

1. Circuit Board Identification

Circuit boards are the backbone of electronic devices, and accurate identification is crucial for efficient assembly and troubleshooting. High-temperature resistant labels are used to mark components, connectors, and test points on circuit boards, enabling technicians to identify and trace the flow of signals effectively. These labels can withstand the high temperatures encountered during soldering, ensuring that the identification information remains intact throughout the manufacturing process.

2. Product Tracking and Traceability

In the electronics industry, tracking and traceability are essential for quality control and regulatory compliance. High-temperature resistant identification labels are used to mark products with unique identifiers such as serial numbers and barcodes. These labels remain legible even when subjected to high temperatures during the product's lifecycle, enabling manufacturers to track and trace products accurately from production to end-user.

3. Equipment and Component Labeling

Electronic equipment and components often operate in high-temperature environments. High-temperature resistant identification labels are used to mark these items, providing crucial information such as model numbers, specifications, and safety warnings. By using these labels, manufacturers ensure that the identification information remains visible and intact, even in extreme conditions, facilitating efficient maintenance and servicing.

4. Ruggedized Electronics

In certain applications, electronic devices need to operate in harsh environments characterized by extreme temperatures, vibrations, and exposure to chemicals. High-temperature resistant identification labels are crucial in such scenarios, as they can withstand the demanding conditions while maintaining legibility. These labels are used to mark components, connectors, and cables in ruggedized electronics, ensuring accurate identification and traceability.

Conclusion

High-temperature resistant identification labels are indispensable in the electronics industry. Their ability to withstand extreme temperatures and maintain legibility ensures efficient operations, accurate tracking, and traceability. Whether it is circuit board identification, product tracking, equipment labeling, or ruggedized electronics, these labels play a vital role in ensuring seamless operations and reliable information. By investing in high-temperature resistant identification labels, manufacturers can enhance productivity, quality control, and customer satisfaction in the fast-paced world of electronics.

We offer comprehensive technical support, including free professional labeling solutions, advice on label materials and adhesive selection, as well as online/offline assistance from professional software and hardware engineers. Service email: andy@ownlikes.cn. In pre-sales, we leverage our extensive experience in specialty labeling projects to provide clients with the most suitable hardware solutions. Additionally, all our label barcode printers and scanners come with a three-year free warranty, demonstrating our confidence in our products.

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.