High-Temperature Resistant Label Paper for Aluminum Panels

Sticker labels play a crucial role in various industries, serving as a means to convey important information, enhance brand visibility, and ensure product identification. When it comes to labeling aluminum panels, a unique challenge arises due to the high temperatures these panels are exposed to during manufacturing and usage. In order to address this challenge, the sticker label industry has developed high-temperature resistant label paper specifically designed for aluminum panels.

The Need for High-Temperature Resistance

Aluminum panels are widely used in industries such as automotive, aerospace, and construction due to their lightweight, durability, and corrosion resistance. However, during the manufacturing process, these panels are subjected to high temperatures, which can range from 200 to 500 degrees Celsius. Ordinary sticker labels cannot withstand such extreme temperatures and would quickly deteriorate, leading to illegible or damaged labels.

To ensure proper labeling and maintain the integrity of information on aluminum panels, it is essential to use high-temperature resistant label paper. This specialized paper is designed to withstand the extreme heat encountered during manufacturing, as well as the subsequent use of aluminum panels in high-temperature environments.

The Composition of High-Temperature Resistant Label Paper

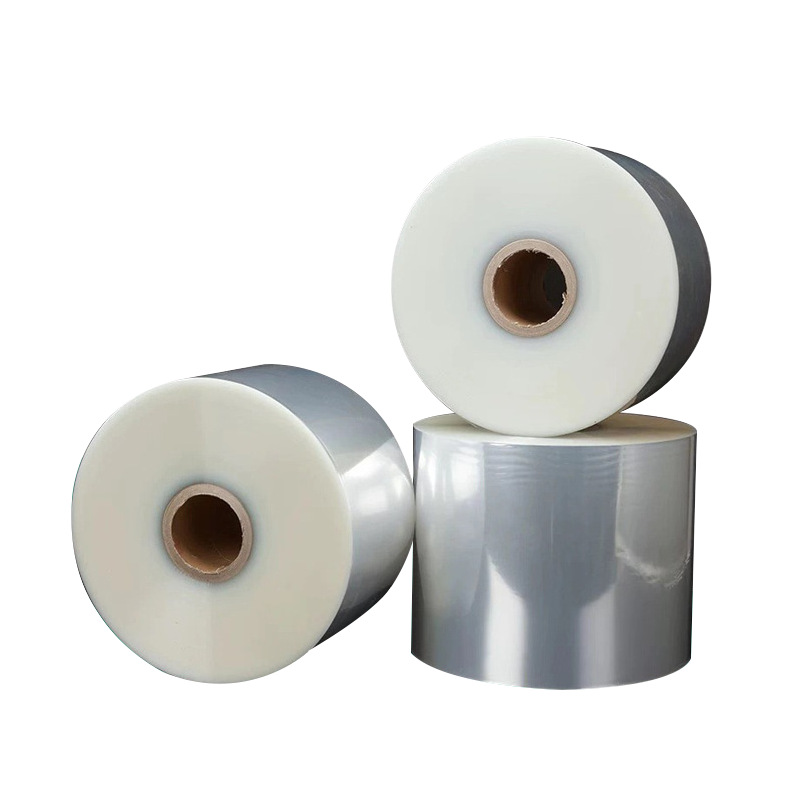

High-temperature resistant label paper is engineered using a combination of advanced materials and adhesive technologies. These labels are typically composed of three layers: the facestock, adhesive layer, and liner.

The facestock layer is the visible part of the label that carries the printed information. It is made from a specially formulated material that can withstand high temperatures without warping or fading. This facestock material is often a combination of synthetic fibers, such as polyester or polyimide, which have excellent thermal stability and resistance to heat-induced degradation.

The adhesive layer is responsible for securely bonding the label to the aluminum panel. It is formulated to withstand the high temperatures encountered during the manufacturing process and maintain its adhesive properties in extreme conditions. Silicone-based adhesives are commonly used in high-temperature resistant label papers due to their excellent thermal stability and resistance to degradation.

The liner layer serves as a protective backing for the label and is removed before application. It is made from a material that can withstand the high temperatures during manufacturing and does not leave any residue on the label or the aluminum panel.

Benefits of High-Temperature Resistant Label Paper

The use of high-temperature resistant label paper offers several benefits in the labeling of aluminum panels:

1. Durability: High-temperature resistant label paper ensures that labels remain intact and legible even under extreme heat conditions, thereby enhancing the longevity of the labeling solution.

2. Information Integrity: Labels made from high-temperature resistant paper maintain the integrity of printed information, preventing smudging, fading, or illegibility due to heat exposure.

3. Regulatory Compliance: Industries such as automotive and aerospace have stringent labeling requirements. High-temperature resistant label paper enables compliance with these regulations by ensuring that labels remain intact and readable throughout the product's lifespan.

4. Enhanced Safety: Accurate and visible labeling on aluminum panels is crucial for safety purposes. High-temperature resistant label paper ensures that important safety information, warning signs, and identification labels remain intact and readable, reducing the risk of accidents or mishaps.

Conclusion

The development of high-temperature resistant label paper has revolutionized the labeling of aluminum panels. By using specialized materials and adhesive technologies, these labels can withstand extreme temperatures, ensuring durability, information integrity, regulatory compliance, and enhanced safety. As industries continue to rely on aluminum panels for their various applications, the sticker label industry's innovation in high-temperature resistant label paper plays a vital role in meeting the unique challenges posed by high-temperature environments.

We offer comprehensive technical support, including free professional labeling solutions, advice on label materials and adhesive selection, as well as online/offline assistance from professional software and hardware engineers. Service email: andy@ownlikes.cn. In pre-sales, we leverage our extensive experience in specialty labeling projects to provide clients with the most suitable hardware solutions. Additionally, all our label barcode printers and scanners come with a three-year free warranty, demonstrating our confidence in our products.

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.