Choosing Heat-Resistant Label Materials: Tips and Recommendations

In the sticker label industry, selecting the right materials for various applications is crucial. One important consideration is heat resistance, as labels often encounter high temperatures during manufacturing, transportation, or usage. In this article, we will provide tips and recommendations for choosing heat-resistant label materials to ensure durability and legibility in challenging environments.

Understanding Heat-Resistant Label Materials

Heat-resistant label materials are specifically designed to withstand elevated temperatures without compromising their adhesive properties or print quality. These materials are commonly used in industries such as automotive, electronics, aerospace, and food packaging, where exposure to heat is a common occurrence.

Tips for Choosing Heat-Resistant Label Materials

1. Determine the temperature range: Identify the highest temperature the label will encounter throughout its lifecycle. This includes exposure to heat during manufacturing processes, transportation, and end-use applications. Knowing the temperature range will help you select materials that can withstand those conditions.

2. Consider the adhesive: The adhesive used in heat-resistant labels must be capable of maintaining its bonding strength even at high temperatures. Look for adhesives that are specifically formulated for heat resistance, as they will ensure that the label remains securely attached to the surface even under extreme conditions.

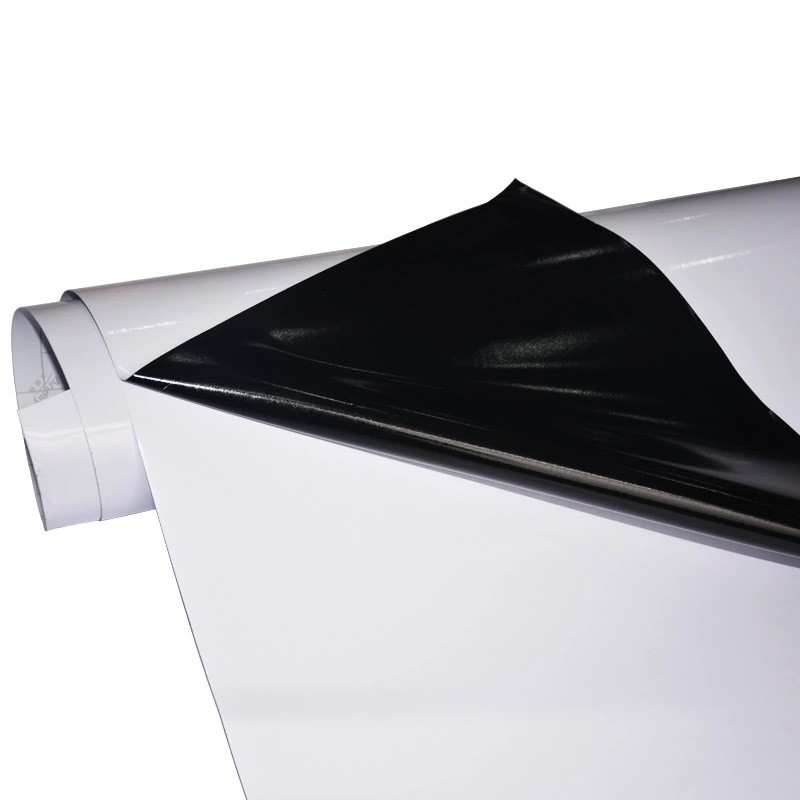

3. Evaluate the facestock material: The facestock material should be able to withstand the heat without warping, discoloration, or degradation. Common heat-resistant facestock materials include polyester, polyimide, and metalized films. Consider the specific requirements of your application and choose a facestock material that best suits your needs.

4. Assess print durability: Labels that are exposed to heat may undergo thermal transfer printing or other printing processes. Ensure that the label material can withstand the printing process without smudging or fading. Look for materials that offer excellent print durability, ensuring that the information remains legible throughout the label's lifespan.

5. Test for chemical resistance: In addition to heat resistance, labels may also come into contact with chemicals or solvents. Verify that the chosen label materials are resistant to these substances to prevent damage or deterioration.

Recommendations for Heat-Resistant Label Materials

1. Polyester (PET) labels: Polyester labels offer excellent heat resistance and durability. They can withstand temperatures up to 200°C (392°F) without warping or losing adhesion. Polyester labels are commonly used in automotive and electronic industries.

2. Polyimide (PI) labels: Polyimide labels are highly heat-resistant and can withstand temperatures up to 300°C (572°F). They are widely used in aerospace, automotive, and electronics industries, where extreme temperatures are encountered.

3. Metalized film labels: Metalized film labels provide exceptional heat resistance and are often used in applications where high temperatures and harsh environments are present. They can withstand temperatures up to 400°C (752°F) without compromising adhesion or print quality.

4. Ceramic labels: Ceramic labels are ideal for applications that require extreme heat resistance, such as furnace labeling or high-temperature manufacturing processes. They can withstand temperatures exceeding 1000°C (1832°F) and offer excellent resistance to chemicals and solvents.

Remember to consult with label material suppliers or experts in the field to ensure you choose the most suitable materials for your specific heat-resistant labeling needs. By selecting the right materials, you can ensure that your labels maintain their integrity, legibility, and adhesion even in challenging environments.

We offer comprehensive technical support, including free professional labeling solutions, advice on label materials and adhesive selection, as well as online/offline assistance from professional software and hardware engineers. Service email: andy@ownlikes.cn. In pre-sales, we leverage our extensive experience in specialty labeling projects to provide clients with the most suitable hardware solutions. Additionally, all our label barcode printers and scanners come with a three-year free warranty, demonstrating our confidence in our products.

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.