Creating Heat-Resistant Labels for Cake Decoration

Sticker labels play a crucial role in the cake decoration industry. They not only provide essential information about the cake but also enhance its visual appeal. However, the challenges faced in this industry are unique, as the labels need to withstand high temperatures during the baking process. In this article, we will explore the process of creating heat-resistant labels for cake decoration, ensuring that they maintain their integrity and aesthetics throughout the baking and decorating process.

The Importance of Heat Resistance

Heat resistance is a critical factor to consider when designing labels for cake decoration. The labels must endure the high temperatures inside an oven without losing their adhesive properties or distorting their appearance. This is essential to ensure that the labels remain securely attached to the cake throughout the baking process, without compromising food safety or visual appeal.

Choosing the Right Materials

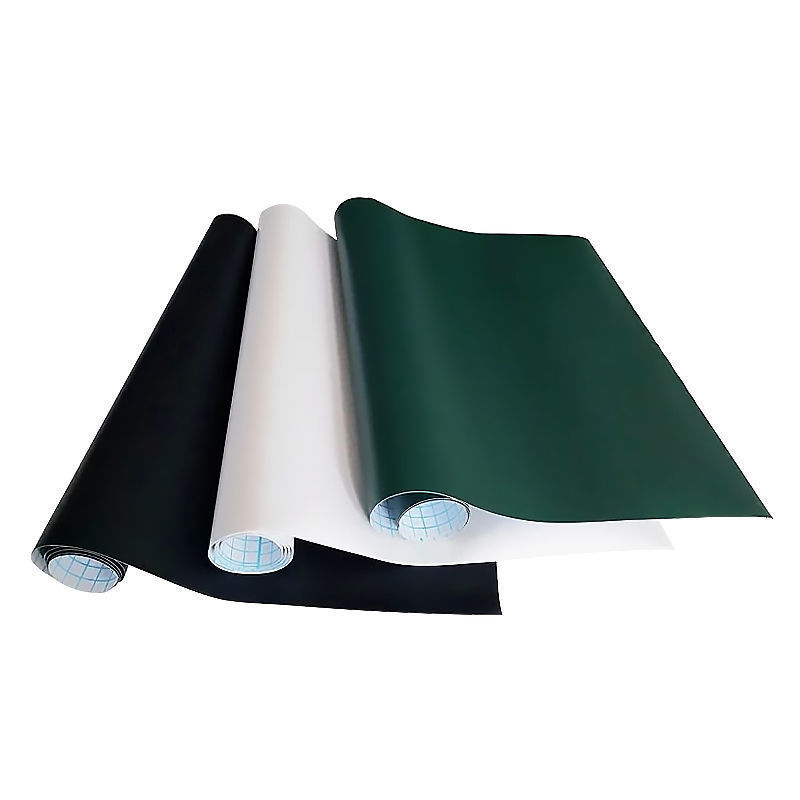

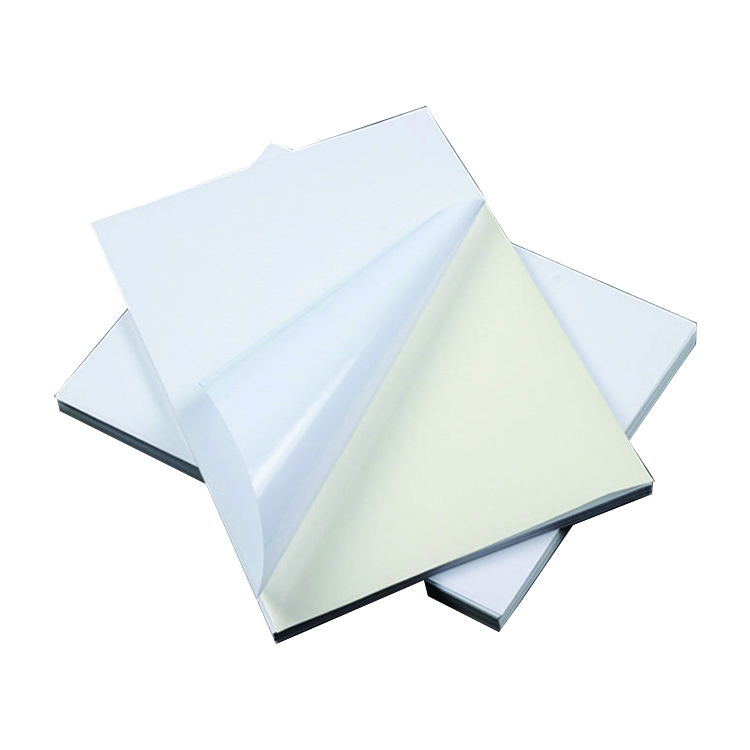

When creating heat-resistant labels for cake decoration, selecting the appropriate materials is paramount. Certain materials, such as standard paper labels, may not withstand the heat and can become damaged or disintegrate during baking. Instead, materials like synthetic films or specialty heat-resistant papers should be considered.

Synthetic films, such as polypropylene or polyester, offer excellent heat resistance properties. They are durable, waterproof, and can withstand temperatures well above those typically used in baking. These films also provide a smooth surface for printing vibrant and high-quality designs, ensuring that the labels maintain their visual appeal.

Specialty heat-resistant papers are another viable option. These papers are specifically designed to withstand high temperatures without losing their integrity. They are often coated with a heat-resistant substance that prevents the paper from burning or disintegrating when exposed to heat. This coating also ensures that the labels remain securely attached to the cake, even during prolonged baking periods.

Printing Techniques

Choosing the right printing technique is crucial to create heat-resistant labels for cake decoration. Traditional inkjet or laser printing methods may not be suitable, as the inks used in these processes can smudge or fade when exposed to high temperatures.

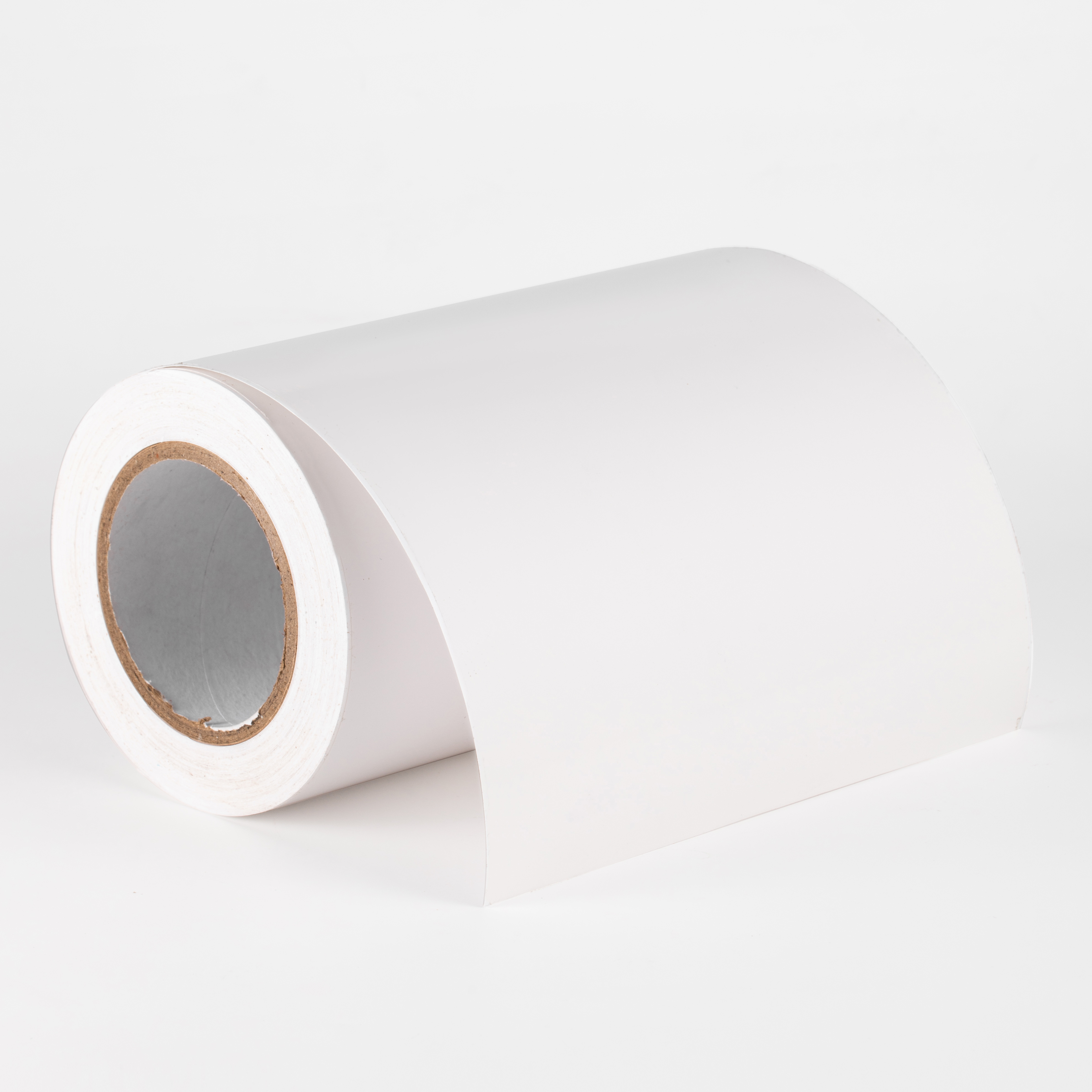

One effective printing technique for heat-resistant labels is thermal transfer printing. This method involves using a thermal transfer ribbon, which contains heat-resistant ink. The ribbon is heated, causing the ink to transfer onto the label material. This process ensures that the ink adheres securely to the label and remains intact even under high temperatures.

Another option is UV-curable printing. This technique involves using UV-curable inks that are instantly cured by exposure to ultraviolet light. The resulting prints are highly durable and resistant to heat, making them suitable for cake decoration labels. UV-curable inks also offer vibrant colors and excellent print quality, enhancing the visual appeal of the labels.

Applying the Labels

Applying heat-resistant labels to cakes requires careful consideration to ensure proper adhesion. The labels should be applied to the cake after it has cooled down from baking but before any frosting or decorations are added. This allows the labels to adhere securely to the cake's surface without being affected by moisture or other ingredients.

It is essential to press the labels firmly onto the cake to ensure proper adhesion. This can be done using a gentle rolling motion with a clean, dry hand or a specialized tool designed for applying labels to delicate surfaces. Taking these precautions will help the labels withstand the rigors of the decorating process and maintain their integrity throughout.

Conclusion

Creating heat-resistant labels for cake decoration is a crucial aspect of the sticker label industry. By choosing the right materials, employing suitable printing techniques, and applying the labels correctly, cake decorators can ensure that their labels withstand high temperatures and maintain their integrity and visual appeal. With these considerations in mind, cake decorators can confidently showcase their creations while providing essential information to customers.

We offer comprehensive technical support, including free professional labeling solutions, advice on label materials and adhesive selection, as well as online/offline assistance from professional software and hardware engineers. Service email: andy@ownlikes.cn. In pre-sales, we leverage our extensive experience in specialty labeling projects to provide clients with the most suitable hardware solutions. Additionally, all our label barcode printers and scanners come with a three-year free warranty, demonstrating our confidence in our products.

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.