High-Temperature Label Design Software: Create Heat-Resistant Labels Easily!

The sticker label industry plays a crucial role in various sectors, including manufacturing, automotive, aerospace, and electronics. Labels are used to provide important information, such as product identification, safety warnings, and tracking details. However, in certain environments where high temperatures are present, traditional labels may fail to withstand the heat, causing readability issues and potential safety hazards. To address this challenge, high-temperature label design software has emerged as a valuable solution, enabling the creation of heat-resistant labels with ease.

The Importance of Heat-Resistant Labels

In industries where extreme temperatures are encountered, it is vital to have labels that can withstand the heat without compromising their functionality. High-temperature labels ensure that critical information remains legible and intact, even in harsh conditions. They are designed to resist heat, chemicals, and other environmental factors, ensuring that the labels maintain their adhesive properties and readability over time.

High-temperature labels find extensive use in applications such as engine components, circuit boards, industrial ovens, and chemical processing plants. These labels must be able to endure temperatures ranging from several hundred to thousands of degrees Fahrenheit, depending on the specific application. Without the right label materials and design, companies risk facing compliance issues, safety risks, and potential product failures.

Introducing High-Temperature Label Design Software

High-temperature label design software offers an intuitive and user-friendly platform for creating heat-resistant labels. This software provides a range of features specifically tailored to withstand extreme temperatures, ensuring that labels remain intact and readable in demanding environments.

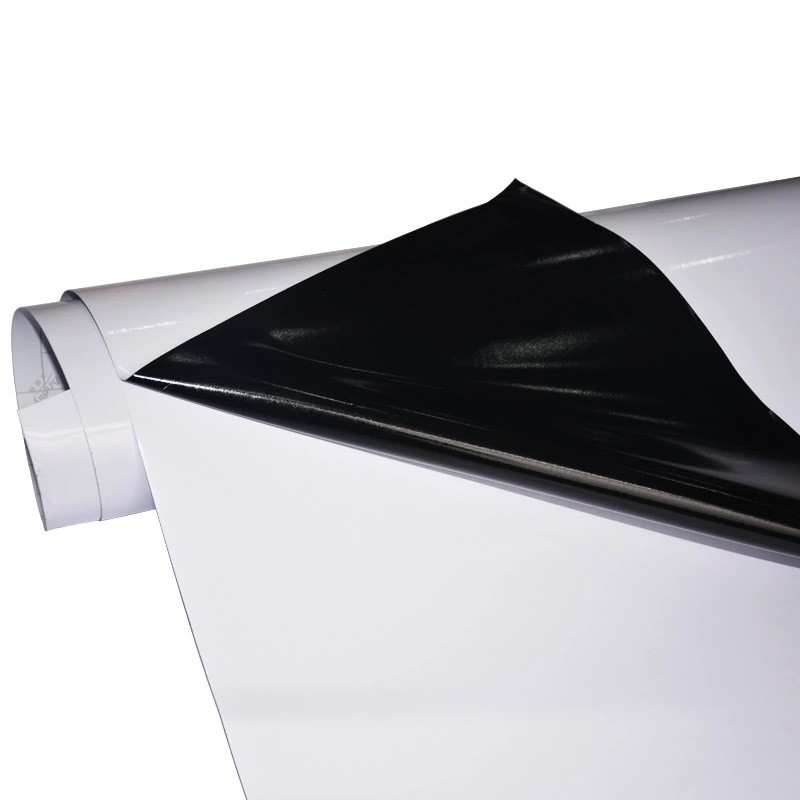

One of the key features of high-temperature label design software is the ability to select appropriate label materials. These software tools offer a wide selection of materials that can withstand high temperatures, including specialized adhesives, coatings, and substrates. Users can choose the most suitable material for their specific application, taking into account factors such as temperature range, chemical resistance, and durability.

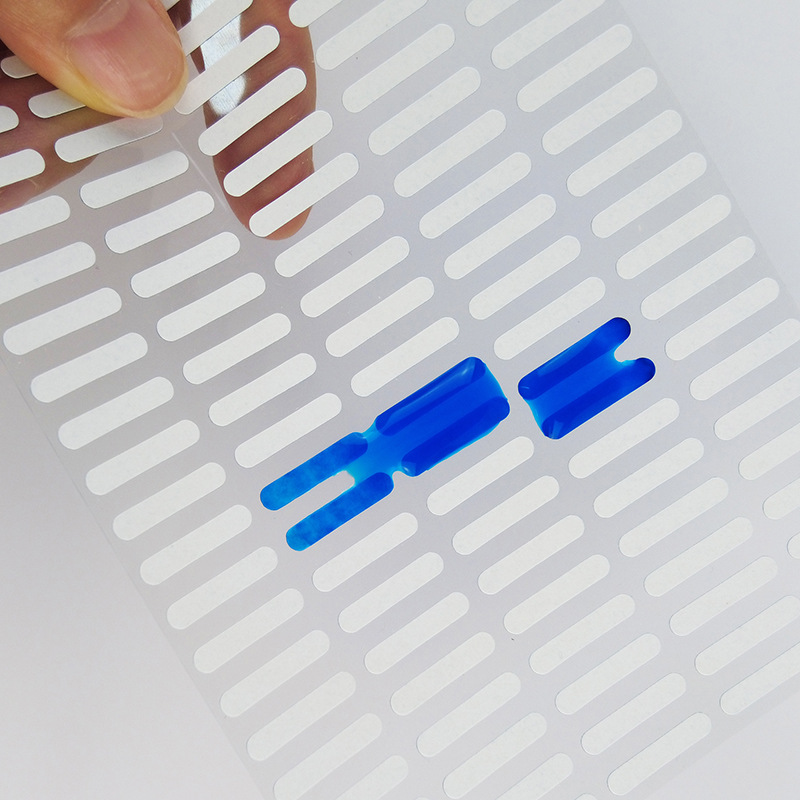

Furthermore, high-temperature label design software provides advanced customization options. Users can easily add text, barcodes, graphics, and other elements to their labels, ensuring that all necessary information is included. The software allows for precise control over label dimensions, fonts, colors, and layouts, enabling users to create professional-looking labels that meet their unique requirements.

The Benefits of High-Temperature Label Design Software

By utilizing high-temperature label design software, companies can experience several key benefits:

- Improved durability: Labels created with high-temperature label design software are specifically engineered to withstand extreme temperatures, ensuring longevity and reliability.

- Enhanced safety: Heat-resistant labels enable clear communication of critical safety information, minimizing the risk of accidents and ensuring compliance with industry regulations.

- Increased productivity: The user-friendly interface and customization options of high-temperature label design software allow for quick and efficient label creation, saving time and resources.

- Cost-effective solution: By preventing label failures and the need for frequent replacements, high-temperature labels can help reduce costs associated with rework and downtime.

Conclusion

In industries where high temperatures are a constant challenge, having heat-resistant labels is essential. High-temperature label design software provides a comprehensive solution for creating durable and reliable labels that can withstand extreme environments. By utilizing this software, companies can ensure the readability and effectiveness of their labels, contributing to improved safety, compliance, and overall operational efficiency.

We offer comprehensive technical support, including free professional labeling solutions, advice on label materials and adhesive selection, as well as online/offline assistance from professional software and hardware engineers. Service email: andy@ownlikes.cn. In pre-sales, we leverage our extensive experience in specialty labeling projects to provide clients with the most suitable hardware solutions. Additionally, all our label barcode printers and scanners come with a three-year free warranty, demonstrating our confidence in our products.

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.