Quotation for High-Temperature Resistant Labels

Introduction High-temperature resistant labels are an essential component in various industries where products are exposed to extreme temperatures. These labels are designed to withstand the harsh conditions of high heat, ensuring that important information and branding remain intact. In this article, we will explore the significance of high-temperature resistant labels in the sticker label industry, their applications, and the factors to consider when providing a quotation for such labels.

Applications of High-Temperature Resistant Labels

1. Automotive Industry In the automotive industry, high-temperature resistant labels are used for various purposes. They are applied to engine components, exhaust systems, and other parts that experience intense heat. These labels help identify critical information, such as part numbers, warnings, and safety instructions, even in extreme conditions.

2. Aerospace Industry Aerospace manufacturers rely on high-temperature resistant labels to ensure the safety and efficiency of their products. These labels are used on engine components, fuel systems, and other critical parts that encounter extreme temperatures during flight. The labels provide crucial information for maintenance, repair, and overall traceability.

3. Electronics Industry With the increasing demand for electronic devices, high-temperature resistant labels play a vital role in the electronics industry. These labels are used on circuit boards, power supplies, and other components that generate significant heat during operation. They provide essential information, such as serial numbers, barcodes, and safety warnings, ensuring accurate identification and compliance.

Factors to Consider for Quotation

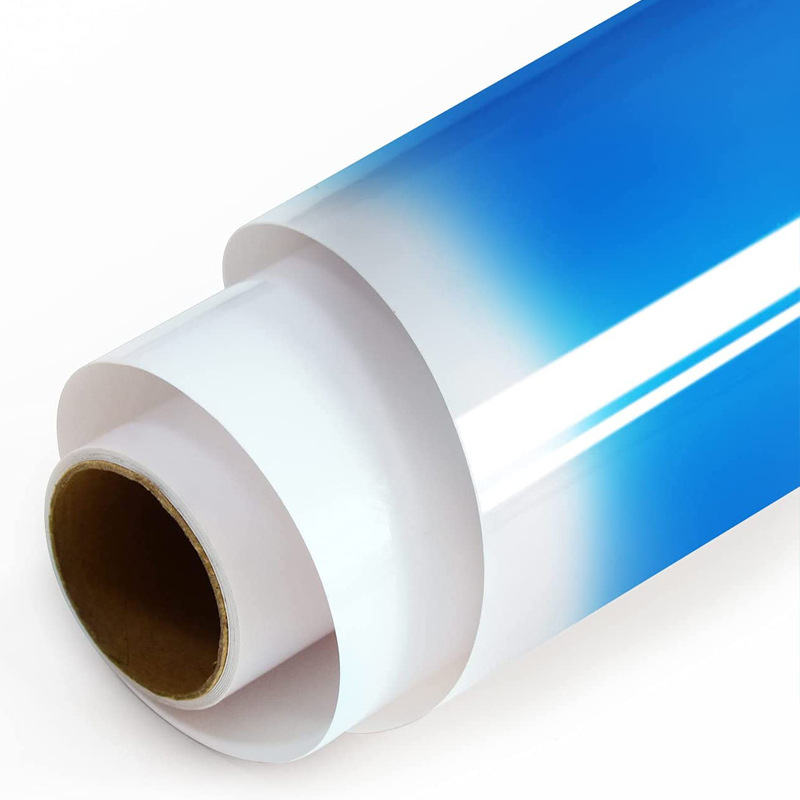

1. Material Selection Choosing the right material is crucial for high-temperature resistant labels. Common options include polyimide, polyester, and ceramic-based materials. Each material has its own advantages and suitability for specific applications. Factors such as temperature range, chemical resistance, and durability should be considered when selecting the material for the labels.

2. Adhesive Properties The adhesive used in high-temperature resistant labels must be capable of withstanding extreme heat without deteriorating or losing adhesion. Factors such as the surface type, temperature range, and duration of exposure should be considered when selecting an adhesive. It is essential to ensure that the adhesive maintains its integrity, preventing label peeling or detachment.

3. Label Design and Printing The design and printing of high-temperature resistant labels should be carefully considered. The label design should incorporate clear and concise information, ensuring readability even in high-temperature environments. Printing techniques, such as thermal transfer or laser printing, should be chosen to ensure durability and resistance to fading or smudging.

4. Regulatory Compliance Certain industries have specific regulations and standards for labeling requirements. It is essential to consider these regulations when providing a quotation for high-temperature resistant labels. Compliance with industry standards ensures that the labels meet the necessary safety and quality requirements.

Conclusion High-temperature resistant labels are indispensable in industries where extreme heat is a constant factor. The automotive, aerospace, and electronics industries heavily rely on these labels to provide critical information, ensure safety, and maintain product integrity. When providing a quotation for high-temperature resistant labels, factors such as material selection, adhesive properties, label design, and regulatory compliance should be carefully considered. By understanding the significance of these factors, sticker label manufacturers can offer tailored solutions that meet the specific needs of their customers in high-temperature environments.

We offer comprehensive technical support, including free professional labeling solutions, advice on label materials and adhesive selection, as well as online/offline assistance from professional software and hardware engineers. Service email: andy@ownlikes.cn. In pre-sales, we leverage our extensive experience in specialty labeling projects to provide clients with the most suitable hardware solutions. Additionally, all our label barcode printers and scanners come with a three-year free warranty, demonstrating our confidence in our products.

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.