High-Temperature Resistant Labels for Electrical Appliances

Sticker labels play a crucial role in the branding, identification, and safety of electrical appliances. As technology advances, electrical appliances are becoming more sophisticated, and they often generate high levels of heat during operation. This necessitates the use of high-temperature resistant labels that can withstand extreme temperatures without compromising their functionality or readability.

The Importance of High-Temperature Resistance

Electrical appliances, such as ovens, stovetops, and industrial machinery, often operate at elevated temperatures. Standard labels may not be able to endure these extreme conditions, leading to issues like fading, peeling, or illegibility. High-temperature resistant labels are designed to withstand the heat generated by these appliances, ensuring that the labels remain intact and readable throughout their lifespan.

These labels are typically made from specialized materials that can withstand temperatures ranging from 150°C (302°F) to 500°C (932°F) or even higher. They are engineered to resist heat, chemicals, and other environmental factors, making them ideal for use in demanding applications.

The Construction of High-Temperature Resistant Labels

High-temperature resistant labels are composed of several layers, each with a specific purpose. The primary layers include:

1. Facestock: The facestock is the visible layer of the label that carries the printed information. It is usually made from materials like polyester, polyimide, or aluminum, which offer excellent heat resistance and durability.

2. Adhesive: The adhesive layer bonds the label to the surface of the appliance. It is specially formulated to withstand high temperatures without melting or losing its adhesive properties. Silicone-based adhesives are commonly used due to their excellent heat resistance.

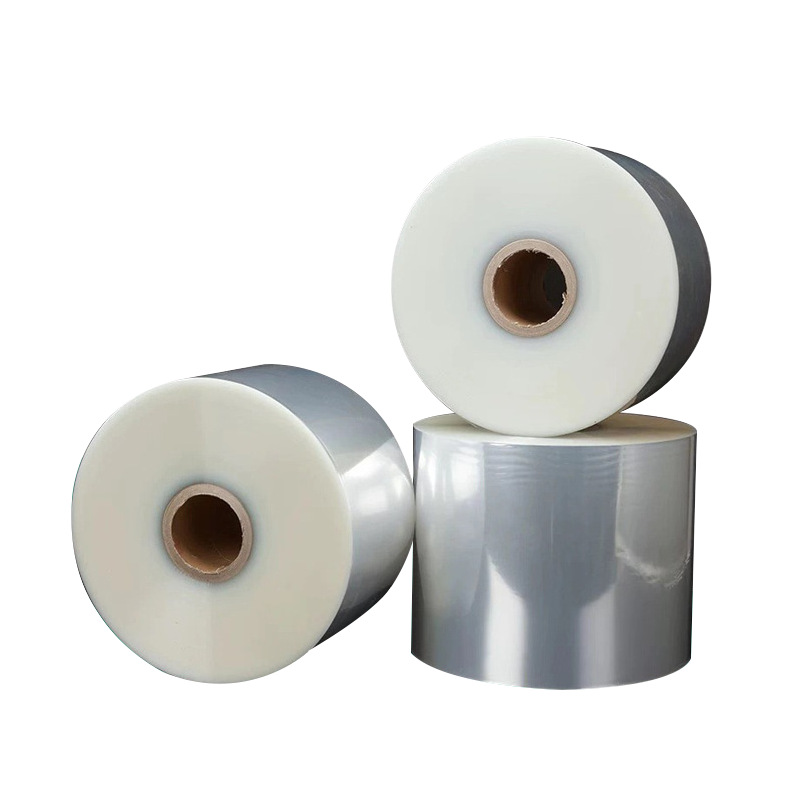

3. Liner: The liner is the backing material that protects the adhesive until the label is applied. It is designed to be easily removable without leaving any residue behind.

Applications of High-Temperature Resistant Labels

High-temperature resistant labels find extensive use in various industries, including:

1. Kitchen Appliances: Ovens, stovetops, microwave ovens, and other cooking appliances generate high levels of heat. High-temperature resistant labels are essential for providing clear instructions, safety warnings, and branding without compromising their readability.

2. Industrial Machinery: Manufacturing plants and industrial machinery often operate at elevated temperatures. Labels used on such equipment need to withstand extreme heat, chemicals, and harsh environments to ensure proper identification, maintenance, and safety.

3. Automotive Industry: In automotive applications, labels need to withstand the heat generated by engines, exhaust systems, and other high-temperature components. These labels are used for identification, warning signs, and branding purposes.

The Benefits of High-Temperature Resistant Labels

High-temperature resistant labels offer several advantages over standard labels, including:

1. Durability: These labels are designed to withstand extreme temperatures, ensuring that they remain intact and readable even in demanding environments.

2. Safety: Labels play a vital role in conveying safety instructions and warnings. High-temperature resistant labels ensure that these messages are clearly visible and legible, reducing the risk of accidents or mishaps.

3. Branding: High-quality labels contribute to the overall branding of electrical appliances. High-temperature resistant labels maintain their appearance and legibility, enhancing the brand's image and customer perception.

In Conclusion

High-temperature resistant labels are essential in the sticker label industry, especially for electrical appliances that generate high levels of heat. These labels provide durability, safety, and clear identification, even in extreme temperature conditions. By utilizing specialized materials and construction techniques, high-temperature resistant labels ensure that crucial information and branding remain intact, contributing to the overall functionality and aesthetics of electrical appliances.

We offer comprehensive technical support, including free professional labeling solutions, advice on label materials and adhesive selection, as well as online/offline assistance from professional software and hardware engineers. Service email: andy@ownlikes.cn. In pre-sales, we leverage our extensive experience in specialty labeling projects to provide clients with the most suitable hardware solutions. Additionally, all our label barcode printers and scanners come with a three-year free warranty, demonstrating our confidence in our products.

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.