High-Temperature Resistant PET Labels: A Must-Have for Extreme Conditions

In the world of sticker label manufacturing, there is a growing demand for labels that can withstand extreme conditions. Industries such as aerospace, automotive, and electronics often require labels that can endure high temperatures without compromising their functionality or appearance. This is where high-temperature resistant PET labels come into play. These labels are designed to meet the stringent requirements of extreme environments, making them a must-have for various industries.

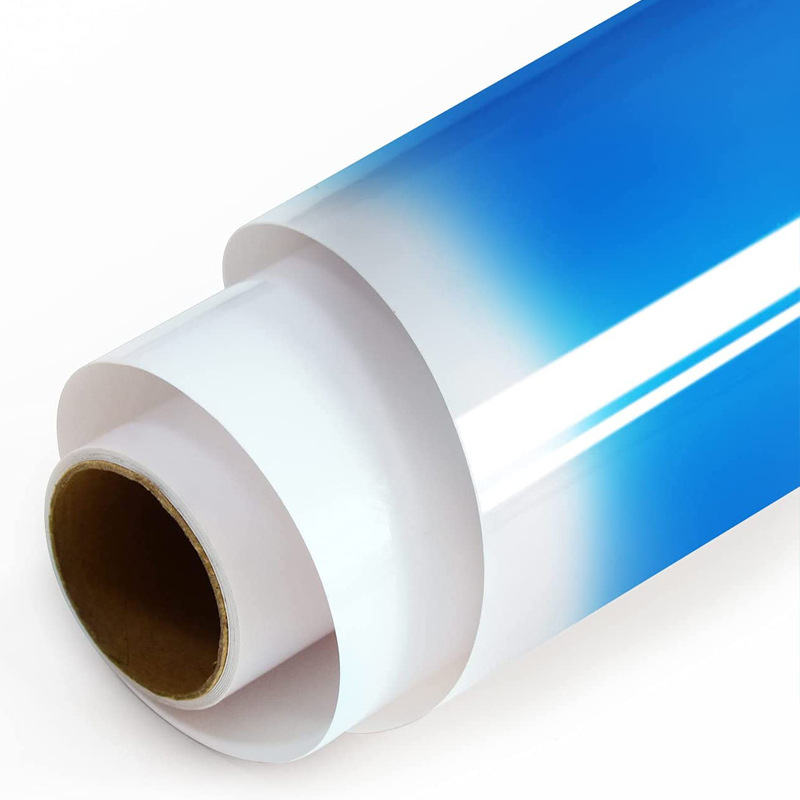

High-temperature resistant PET labels are made from polyethylene terephthalate (PET), a durable and versatile material known for its excellent thermal stability. PET labels are specifically engineered to withstand temperatures ranging from -40°C to 150°C, making them ideal for applications in extreme conditions.

One of the key advantages of high-temperature resistant PET labels is their ability to maintain their adhesive properties even at elevated temperatures. The adhesive used in these labels is formulated to withstand the heat without melting or losing its stickiness. This ensures that the labels remain securely attached to the surface they are applied to, even in the harshest of environments.

Furthermore, high-temperature resistant PET labels offer exceptional resistance to chemicals, solvents, and UV radiation. This makes them suitable for use in industries where exposure to harsh chemicals or intense sunlight is common. The labels' resistance to chemicals and UV radiation ensures that the information printed on them remains legible and intact, providing crucial identification and safety instructions.

The versatility of high-temperature resistant PET labels extends beyond their ability to withstand extreme temperatures and harsh environments. These labels can be customized to meet specific requirements, including size, shape, color, and design. This flexibility allows businesses to create labels that align with their branding and product specifications, while still ensuring the labels can endure the demanding conditions they will be exposed to.

When it comes to application methods, high-temperature resistant PET labels can be easily applied using various techniques. They can be adhered to surfaces using pressure-sensitive adhesives, heat transfer methods, or even through shrink sleeves. The ease of application ensures that businesses can efficiently integrate these labels into their production processes without any disruptions or complications.

In conclusion, high-temperature resistant PET labels are an essential component in industries that face extreme conditions. Their ability to withstand high temperatures, chemicals, solvents, and UV radiation makes them a reliable choice for applications in aerospace, automotive, and electronics sectors. With their customizable options and easy application methods, these labels provide businesses with a practical and durable solution for their labeling needs. When it comes to extreme environments, high-temperature resistant PET labels are truly a must-have.

We offer comprehensive technical support, including free professional labeling solutions, advice on label materials and adhesive selection, as well as online/offline assistance from professional software and hardware engineers. Service email: andy@ownlikes.cn. In pre-sales, we leverage our extensive experience in specialty labeling projects to provide clients with the most suitable hardware solutions. Additionally, all our label barcode printers and scanners come with a three-year free warranty, demonstrating our confidence in our products.

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.