Customized Price for High-Temperature Resistant Label Barcodes

In the ever-evolving landscape of the sticker label industry, one particular segment has been gaining significant attention - high-temperature resistant label barcodes. These specialized labels are designed to withstand extreme temperatures, making them ideal for industries such as automotive, aerospace, electronics, and manufacturing, where products undergo rigorous heat exposure. In this article, we will delve into the intricacies of customized pricing for high-temperature resistant label barcodes, highlighting the key factors that influence costs and the benefits they offer.

Understanding High-Temperature Resistant Label Barcodes

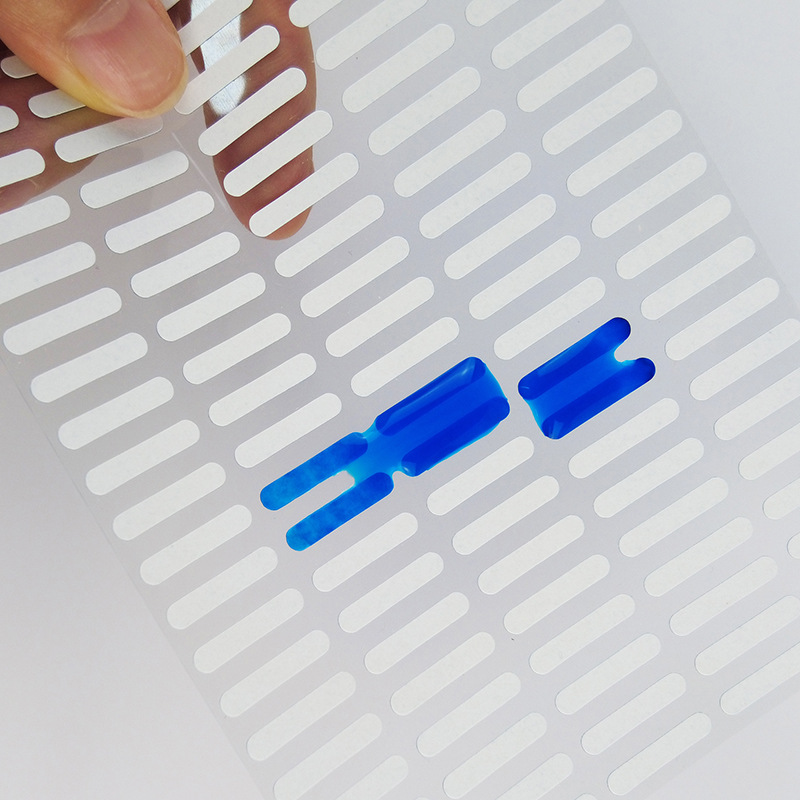

High-temperature resistant label barcodes are specifically engineered to withstand extreme temperatures without compromising their functionality. These labels are made from durable materials, such as polyester or polyimide, which possess exceptional resistance to heat, chemicals, and other environmental factors. Additionally, they are equipped with adhesives that maintain their integrity even in the face of extreme heat.

These labels find extensive usage in industries where products are subjected to high-temperature processes, such as powder coating, soldering, or heat treatment. By utilizing high-temperature resistant label barcodes, businesses can ensure that their products are accurately identified and tracked throughout the manufacturing and supply chain processes, even in the most demanding environments.

Factors Influencing Customized Pricing

When it comes to customized pricing for high-temperature resistant label barcodes, several factors come into play. These factors are crucial in determining the final cost of the labels and ensuring that they meet the specific requirements of each industry.

1. Material Selection: The choice of materials significantly impacts the durability and performance of high-temperature resistant label barcodes. Premium materials, such as polyimide, offer superior resistance to extreme temperatures and harsh chemicals but may be more expensive compared to other options.

2. Label Size and Shape: The size and shape of the label influence the amount of material required and the complexity of the manufacturing process. Irregular shapes or larger sizes may require additional customization, resulting in higher costs.

3. Adhesive Properties: The adhesive used in high-temperature resistant label barcodes must be carefully selected to ensure it can withstand the specific temperature range required. Adhesives with exceptional heat resistance are often more expensive due to their specialized nature.

4. Printing Techniques: The printing method employed for these labels can also impact pricing. Advanced printing techniques, such as thermal transfer printing or laser etching, may incur additional costs but offer superior print quality and durability.

5. Quantity and Lead Time: The volume of labels required and the lead time provided for production can influence the overall pricing. Larger quantities often result in reduced unit costs, while urgent orders or smaller quantities may incur additional fees.

The Benefits of High-Temperature Resistant Label Barcodes

Investing in high-temperature resistant label barcodes brings numerous advantages to businesses operating in demanding environments. Some key benefits include:

1. Enhanced Product Traceability: High-temperature resistant label barcodes ensure accurate product identification and tracking, enabling businesses to maintain a reliable record of their inventory throughout the manufacturing and distribution processes.

2. Improved Efficiency and Productivity: By utilizing durable labels that can withstand extreme temperatures, businesses can streamline their operations, reduce errors, and increase overall productivity.

3. Compliance with Industry Standards: Many industries have specific labeling requirements, especially when it comes to high-temperature environments. Customized high-temperature resistant label barcodes ensure compliance with these standards, avoiding potential penalties or rejections.

4. Cost Savings: Although high-temperature resistant label barcodes may involve higher upfront costs, their durability and resistance to extreme conditions result in longer-lasting labels. This reduces the need for frequent label replacements, leading to cost savings in the long run.

Conclusion

As industries continue to push the boundaries of temperature extremes, the demand for high-temperature resistant label barcodes continues to grow. Customized pricing for these labels takes into account various factors, including material selection, label size, adhesive properties, printing techniques, quantity, and lead time. By investing in high-temperature resistant label barcodes, businesses can ensure product traceability, improve efficiency, comply with industry standards, and achieve long-term cost savings. Embracing these specialized labels is a strategic move for industries that operate in high-temperature environments, providing them with a competitive edge in an increasingly demanding market.

We offer comprehensive technical support, including free professional labeling solutions, advice on label materials and adhesive selection, as well as online/offline assistance from professional software and hardware engineers. Service email: andy@ownlikes.cn. In pre-sales, we leverage our extensive experience in specialty labeling projects to provide clients with the most suitable hardware solutions. Additionally, all our label barcode printers and scanners come with a three-year free warranty, demonstrating our confidence in our products.

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.