Cost of Customizing High-Temperature Resistant Label Barcodes

In the sticker label industry, the demand for high-temperature resistant labels has been steadily increasing. These labels are specifically designed to withstand extreme temperatures, making them suitable for various applications in industries such as automotive, aerospace, and manufacturing. However, the customization of high-temperature resistant label barcodes comes with its own set of costs and considerations.

Understanding High-Temperature Resistant Labels

High-temperature resistant labels are manufactured using specialized materials and adhesives that can withstand extreme temperatures. These labels are designed to maintain their integrity and readability even when exposed to heat, chemicals, and other harsh conditions. The barcode on these labels plays a crucial role in tracking and identifying products throughout their lifecycle.

Factors Affecting the Cost of Customization

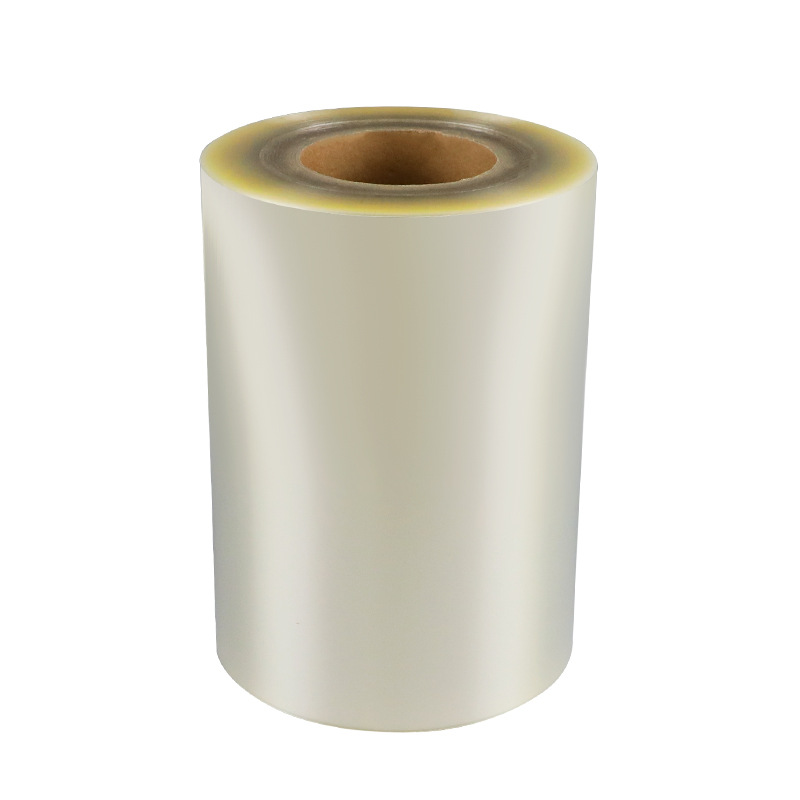

1. Material Selection: The choice of materials used for high-temperature resistant labels significantly impacts the overall cost. Different materials have varying levels of durability and resistance to heat, chemicals, and UV exposure. Labels made from materials such as polyester, polyimide, or ceramic are commonly used for high-temperature applications.

2. Printing Techniques: The printing technique employed for barcode customization also affects the cost. Thermal transfer printing, laser etching, and screen printing are commonly used methods. Each technique has its own set of advantages and limitations, impacting the final cost of customization.

3. Barcode Specifications: The complexity and size of the barcode directly impact the cost. Barcodes with intricate designs or smaller sizes may require more precise printing techniques, which can increase the overall customization cost.

4. Quantity: The volume of labels required for customization can also influence the cost. Larger quantities often come with economies of scale, resulting in lower costs per label. However, smaller quantities may have higher unit costs due to setup and material waste.

Benefits of Customizing High-Temperature Resistant Label Barcodes

1. Enhanced Durability: High-temperature resistant labels are designed to withstand extreme conditions, ensuring that the barcode remains readable throughout the product's lifecycle. This durability reduces the need for label replacements, saving both time and money.

2. Improved Traceability: Customized barcodes allow for efficient tracking and identification of products, enhancing supply chain management and reducing errors. This improves overall productivity and reduces costs associated with lost or misidentified products.

3. Compliance with Industry Standards: Many industries have specific labeling requirements, especially in sectors such as automotive and aerospace. Customizing high-temperature resistant label barcodes ensures compliance with these standards, avoiding penalties and rejections.

Conclusion

Customizing high-temperature resistant label barcodes involves careful consideration of various factors such as material selection, printing techniques, barcode specifications, and quantity. While the cost of customization may vary depending on these factors, the benefits of using high-temperature resistant labels outweigh the expenses. Enhanced durability, improved traceability, and compliance with industry standards make these labels a valuable investment for businesses operating in extreme environments.

We offer comprehensive technical support, including free professional labeling solutions, advice on label materials and adhesive selection, as well as online/offline assistance from professional software and hardware engineers. Service email: andy@ownlikes.cn. In pre-sales, we leverage our extensive experience in specialty labeling projects to provide clients with the most suitable hardware solutions. Additionally, all our label barcode printers and scanners come with a three-year free warranty, demonstrating our confidence in our products.

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.